Cleaning device for ground lenses of optical glasses

A technology for optical glasses and a cleaning device, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as cumbersome operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

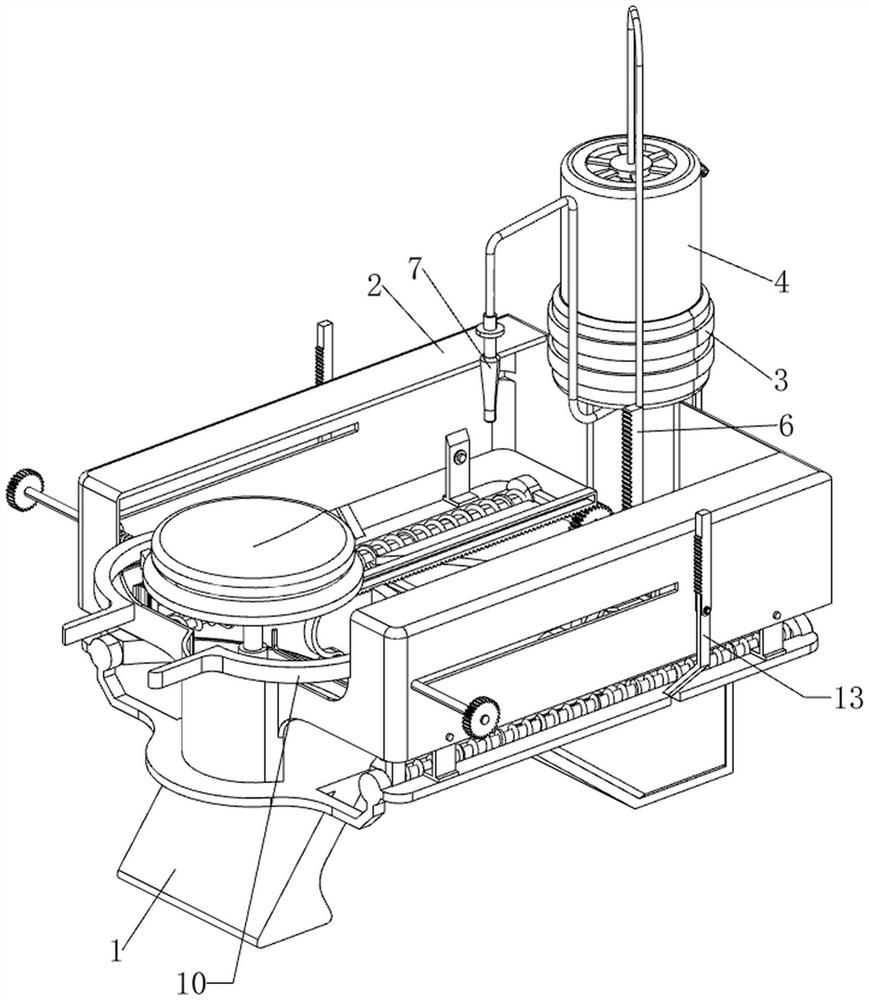

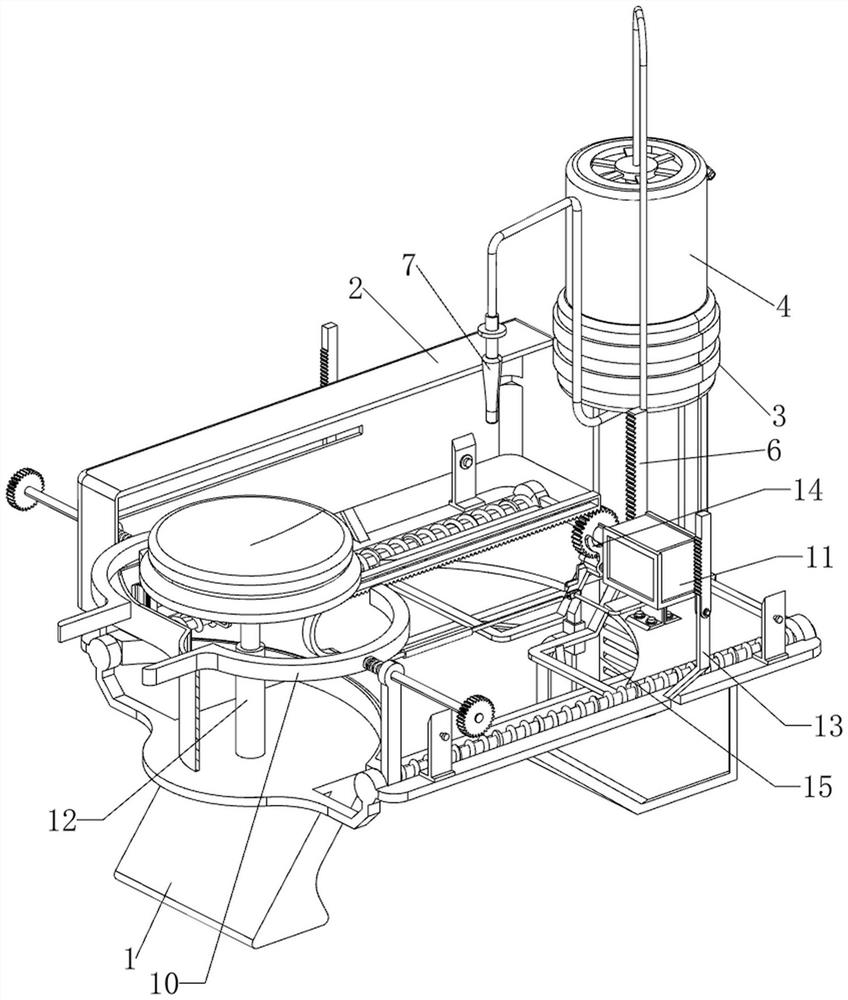

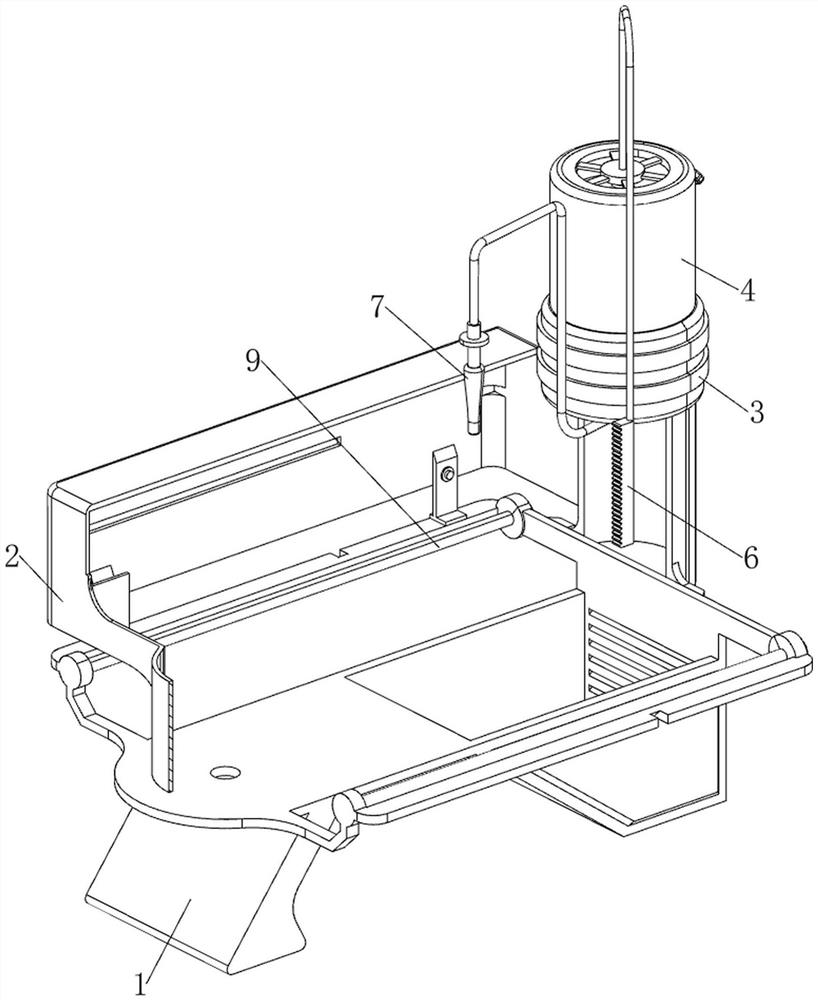

[0036] A lens cleaning device after grinding of optical glasses, referring to Figure 1-8 As shown, it includes a base 1, a side plate 2, a first mounting plate 3, a water tank 4, a lower pressing plate 5, a first rack 6, a nozzle 7, a first spring 8, a first guide rod 9, a clamping mechanism 10 and The moving mechanism 11, the top left side of the base 1 is provided with a side plate 2 by welding, the right side of the side plate 2 is provided with a first mounting plate 3, the bottom of the first mounting plate 3 is connected to the base 1, and the inside of the first mounting plate 3 passes The welding mode is provided with a water tank 4, and the water tank 4 is used to hold water for cleaning work. The middle part of the right side of the water tank 4 is slidingly provided with a lower pressure plate 5, and a first spring 8 is connected between the lower part of the rear side of the lower pressure plate 5 and the water tank 4. The front side of the bottom of the pressure ...

Embodiment 2

[0041] On the basis of embodiment 1, refer to figure 2 , Figure 9 and Figure 10 As shown, it also includes a placement mechanism 12, which is convenient for the clamping plate 101 to clamp the lens. The placement mechanism 12 includes a second hollow cylinder 120, a placement plate 121 and a fifth spring 122. The left side of the top of the base 1 is welded The second hollow tube 120 is provided in the same way, the second hollow tube 120 is slidingly provided with a placement plate 121, the placement plate 121 is used to place the lens, and the fifth spring 122 is connected between the bottom of the placement plate 121 and the second hollow tube 120 .

[0042] refer to figure 2 and Figure 11 As shown, a turning mechanism 13 is also included, and the turning mechanism 13 can automatically rotate the lens. The turning mechanism 13 includes a second gear 130, a second guide rod 131, a sixth spring 132, a connecting plate 133 and a third rack 134, The outer ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com