Device and method for reducing fluoride through thermal plasma

A thermal plasma and plasma torch technology, which is applied in the field of devices for ion reduction of fluoride, can solve problems such as secondary pollution, and achieve the effects of less secondary pollution, easy industrialization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

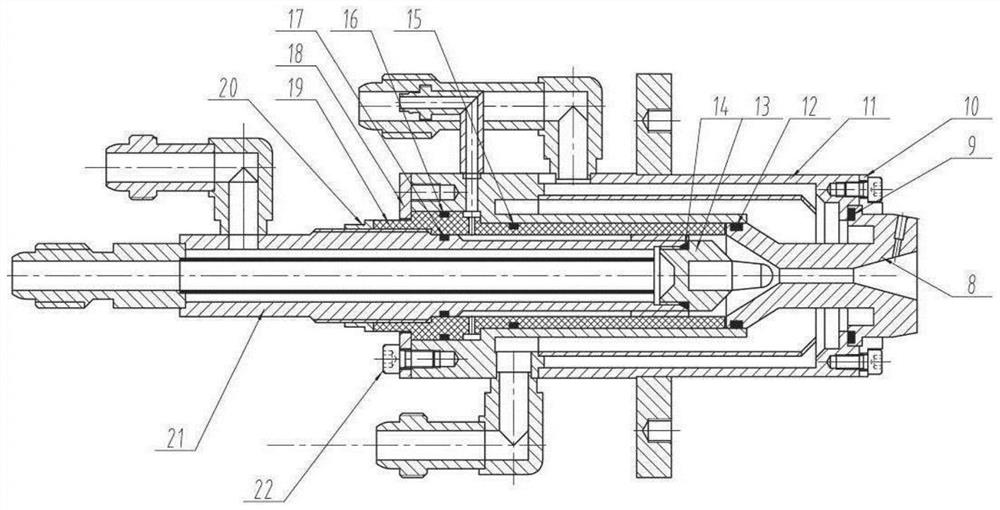

Image

Examples

Embodiment 1

[0040] In this embodiment, carbon tetrafluoride CF 4 , using thermal plasma to reduce carbon tetrafluoride to generate simple carbon, which specifically includes the following steps:

[0041] Step 1. Vacuumize the reaction chamber

[0042] Pump the vacuum in the reaction chamber to less than 5×10 -3 Pa, until it reaches 2~3×10 -3 After Pa, fill the reaction chamber with argon to 10 3 Pa, its purpose is to remove the air in the reaction chamber and prevent the product from being oxidized during the reduction reaction;

[0043] Step 2, Turn on and adjust the DC arc plasma torch until it runs stably

[0044] Turn on the DC arc plasma torch, the working gas is argon, and the flow rate is 3m 3 / h, adjust the power of the plasma torch to 50kW until it runs stably;

[0045] Step 3, mixing gaseous fluoride and hydrogen into the plasma torch for reduction treatment

[0046] The carbon tetrafluoride gas to be reduced and the hydrogen gas are uniformly mixed at a flow rate of 20sc...

Embodiment 2

[0051] In this example, sulfur hexafluoride SF 6 As the fluoride to be reduced, the reduction of fluoride is carried out, which specifically includes the following steps:

[0052] Step 1. Vacuumize the reaction chamber

[0053] Pump the vacuum in the reaction chamber to less than 5×10 -3 Pa, until it reaches 2~3×10 -3 After Pa, fill the reaction chamber with argon to 10 3 Pa, its purpose is to remove the air in the reaction chamber and prevent the product from being oxidized during the reduction reaction;

[0054] Step 2, Turn on and adjust the DC arc plasma torch until it runs stably

[0055] Turn on the DC arc plasma torch, the working gas is argon, and the flow rate is 3m 3 / h, adjust the power of the plasma torch to 50kW until it runs stably;

[0056] Step 3, mixing gaseous fluoride and hydrogen into the plasma torch for reduction treatment

[0057] The sulfur hexafluoride gas to be reduced and the hydrogen gas are uniformly mixed at a flow rate of 20sccm and 30sccm...

Embodiment 3

[0062] In this example, tungsten hexafluoride WF 6 As the fluoride to be reduced, the reduction of fluoride is carried out, which specifically includes the following steps:

[0063] Step 1. Vacuumize the reaction chamber

[0064] Pump the vacuum in the reaction chamber to less than 5×10 -3 Pa, until it reaches 2~3×10 -3 After Pa, fill the reaction chamber with argon to 10 3 Pa, its purpose is to remove the air in the reaction chamber and prevent the product from being oxidized during the reduction reaction;

[0065] Step 2, Turn on and adjust the DC arc plasma torch until it runs stably

[0066] Turn on the DC arc plasma torch, the working gas is argon, and the flow rate is 3m 3 / h, adjust the power of the plasma torch to 50kW until it runs stably;

[0067] Step 3, mixing gaseous fluoride and hydrogen into the plasma torch for reduction treatment

[0068] The tungsten hexafluoride gas and hydrogen gas to be reduced are uniformly mixed at a flow rate of 20sccm and 30sccm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com