High-performance CPP film and preparation process thereof

A preparation process and high-performance technology, applied in the field of CPP film, can solve problems such as difficult outflow of raw materials, waste of raw materials, and inability to accurately grasp the quality of CPP film products, so as to achieve the effect of ensuring output quality and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

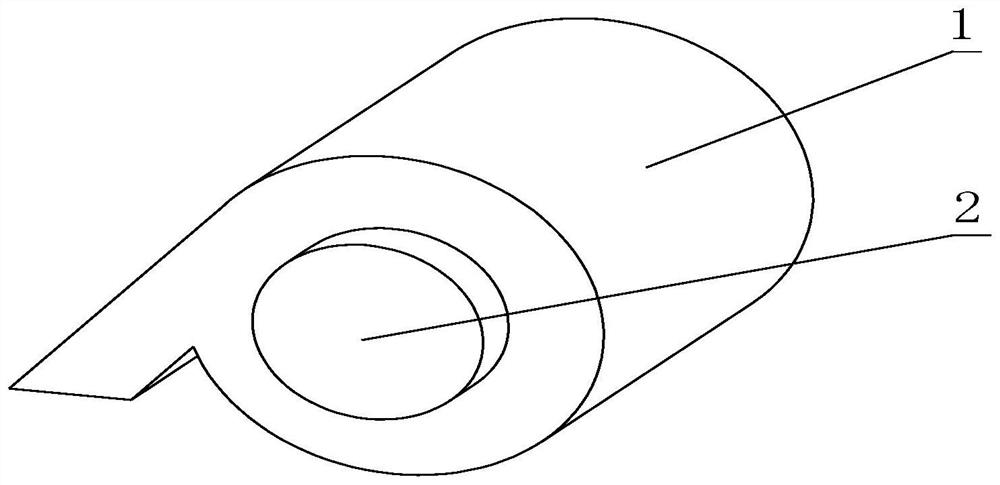

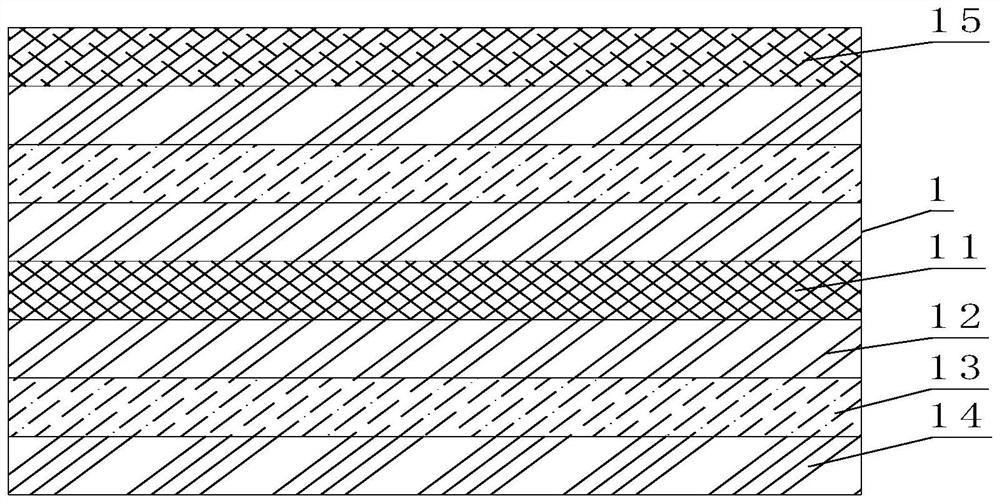

[0047] First aspect, such as Figure 1-5 As shown, the present invention provides a kind of high-performance CPP film, comprises CPP film 1, and the surface of CPP film 1 is provided with wrapping roller 2, and CPP film 1 comprises CPP film body 11, and the surface of CPP film body 11 is fixedly connected with glass Fiber membrane 12, the surface of glass fiber membrane 12 is fixedly connected with aramid fiber membrane 13, the surface of aramid fiber membrane 13 is fixedly connected with wear-resistant coating 14, and the surface of wear-resistant coating 14 is provided with self-adhesive protective film 15.

[0048]In the present embodiment, the setting of the self-adhesive protective film 15, the self-adhesive protective film 15 will always be attached to the surface of the wear-resistant coating 14 during the transportation of the CPP film 1, until the CPP film 1 is transported to a suitable position, the The self-adhesive protective film 15 is torn off, and the CPP film 1...

Embodiment 2

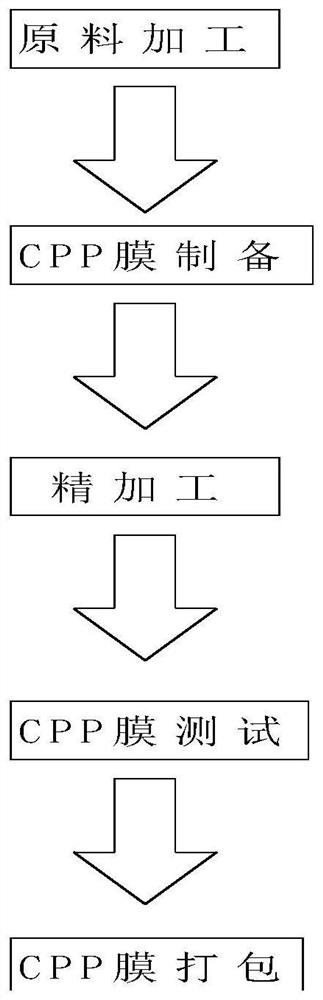

[0050] Second aspect, such as Figure 1-5 Shown, the present invention also provides a kind of preparation technology of high-performance CPP film, the preparation technology of this high-performance CPP film, comprises the following steps:

[0051] Step 1: raw material processing;

[0052] Step 2: CPP film 1 preparation;

[0053] Step three: finishing;

[0054] Step 4: CPP film 1 test;

[0055] Step 5: CPP film 1 is packaged.

[0056] Wherein step one also includes the following steps:

[0057] A1: put the raw material into the crushing device 3 for crushing;

[0058] A2: The pulverized raw materials are accurately measured by the weighing device 4 .

[0059] Wherein step two also includes the following steps:

[0060] B1: In the dust-free workshop, the raw materials are processed through the stirring device, the dispersing device and the drying device;

[0061] B2: Casting a film through a casting film forming machine.

[0062] Wherein step three also includes the f...

Embodiment 3

[0074] Such as Figure 1-5 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the crushing device 3 includes a vibrating mechanism 32, and the vibrating mechanism 32 includes a vibrating shell 321, and the bottom of the inner wall of the vibrating shell 321 is fixedly connected with a No. 2 motor 326, the output end of the No. 2 motor 326 is fixedly connected with the No. 2 rotating rod 323, and the surface of the No. 2 rotating rod 323 is fixedly connected with the chuck 329, and the top of the chuck 329 is lapped with the fixed disk 325, and the surface of the fixed disk 325 is fixed. Connected with an elastic rod 328, the other end of the elastic rod 328 is fixedly connected with a knocking block 327, the inside of the fixed plate 325 is provided with a threaded rod 324, the top of the threaded rod 324 extends to the top of the fixed plate 325, and the bottom of the threaded rod 324 extends To the bottom of the chuck 329...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com