Friction plate with protrusion structures

A friction plate and main body technology is applied in the field of friction plates with a convex structure, which can solve the problems of difficult long-term use, troublesome maintenance, and short life of the friction plates, and achieve the effects of high wear resistance, long service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

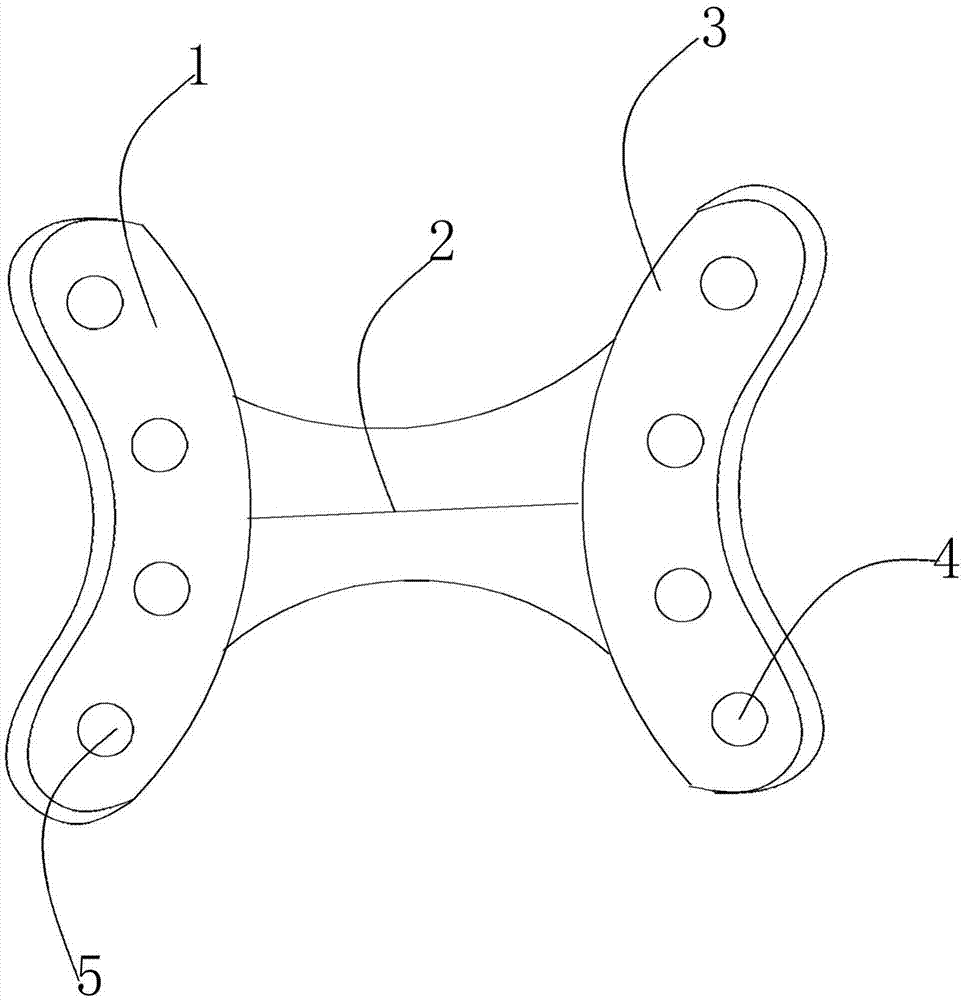

[0008] refer to figure 1 , A friction plate with a raised structure disclosed in this embodiment includes a main body and a fixed plate 2, and is characterized in that: the main body includes a friction plate A1 and a friction plate B3, and the friction plate A1 and the friction plate B3 are fixed by The plates 2 are connected, the friction plate A1 is provided with a protruding structure A5, and the friction plate B3 is provided with a protruding structure B4.

[0009] By adopting the above-mentioned technical solution, the beneficial effect of the present invention is: the structure is simple, it can play a frictional effect on two rotating shafts or runners at the same time, and the friction plate is also provided with a raised structure, which is more wear-resistant during use; As mentioned above, the present invention has the characteristics of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com