Floating friction holding mechanism for main reducer assembly flange

A main reducer and flange technology, applied in the field of the main reducer assembly flange floating friction holding mechanism, can solve the problems of difficulty in guaranteeing reliability and compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

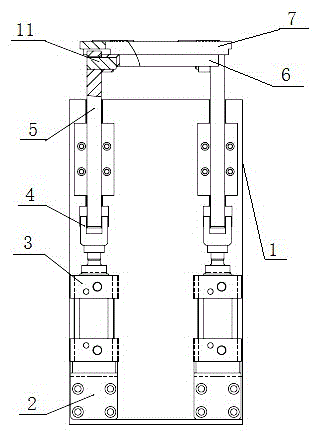

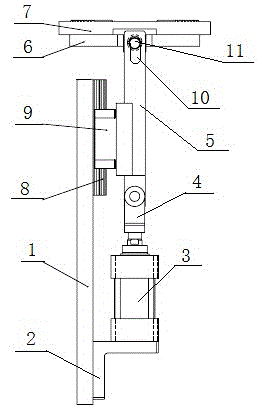

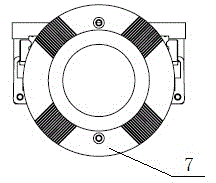

[0016] See figure 1 — image 3 , a main reducer assembly flange floating friction gripping mechanism, including a mounting plate 1, two cylinder bases 2 fixed on the mounting plate 1, two cylinders 3 installed on the corresponding cylinder bases 2, two The bottom end is connected to the piston rod of the corresponding cylinder 3 through the cylinder installation trunnion 4. The connecting rod 5 connected to the top of the two connecting rods 5 is connected to the clamping disc chassis 6, and the flange is fixed on the upper end surface of the clamping disc chassis 6. The tight disk 7, the guide rail 8 arranged on the mounting plate 1, and the slide block 9 slidably arranged on the guide rail 8, wherein the top ends of the two connecting rods 5 are connected to the outer circumference of the tight disk chassis 6 and arranged oppositely , the slider 9 is fixedly connected to the connecting rod 5, the top of the connecting rod 5 is provided with a waist hole 10, and the pin shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com