Laser film carving machine for thin-film solar cell panel

A solar panel, laser engraving technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, to achieve the effect of improving production efficiency and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

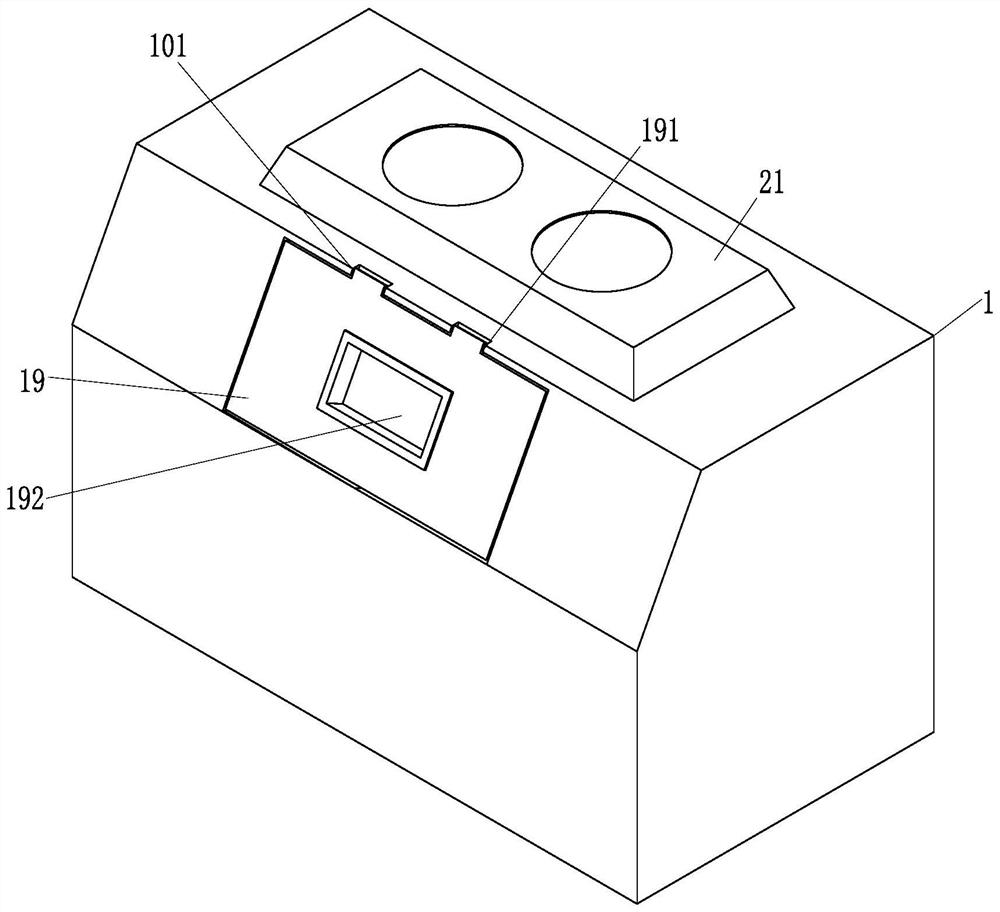

[0035] As a specific embodiment of the present invention, a light-shielding observation window 192 is provided in the middle of the cover plate 19 .

[0036] During the processing of thin-film solar panels, due to the need for sealing and safety of the processing environment, the cover plate 19 cannot be easily lifted, but the cover plate 19 and the box body 1 block the personnel from observing the inside of the box body 1. Thereby affecting the staff's understanding of the internal processing progress of the box body 1, and then unable to ensure continuous, efficient and safe production. Therefore, a light-shielding observation window 192 is provided in the middle of the cover plate 19, and the staff can pass through the dark-light and transparent light-shielding observation window 192. Observing the internal situation of the box 1 not only ensures the safety of personnel, but also ensures the orderly progress of production. At the same time, the observation window is treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com