Rapid stamping production device for metal trough plate

A production device and metal groove technology, applied in the field of stamping equipment, can solve the problems of complex production process, offset of feeding and processing, inaccurate position of punching holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

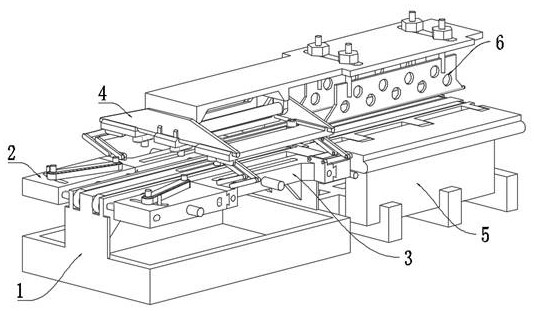

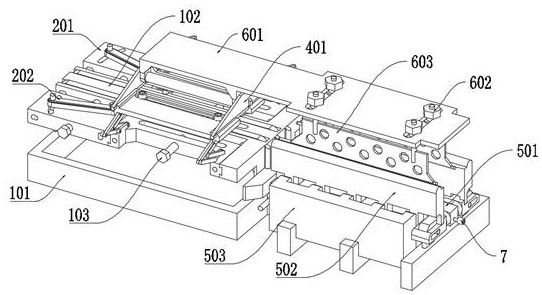

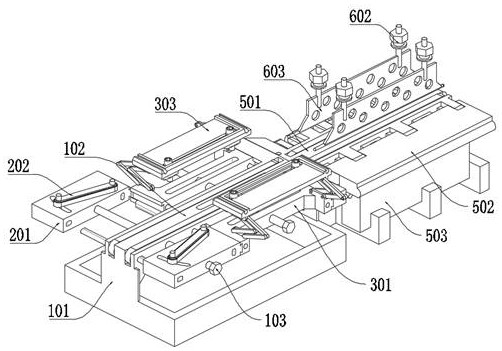

[0057] as attached figure 1 to attach Figure 8 Shown:

[0058] The present invention provides a rapid stamping production device for metal slats, including a base structure 1;

[0059] Feeding structure 2, the feeding structure 2 is provided with the same two groups before and after, and the two groups of feeding structures 2 are all slidably installed on the base structure 1;

[0060] The bearing structure 3 is slidably installed on the right side of the feeding structure 2, and the upper end of the bearing structure 3 is connected with a stamping structure 4, and the stamping structure 4 and the bearing structure 3 are parallel to each other;

[0061] Bending structure 5, the bending structure 5 is set to be slidably installed on the rightmost position of the base structure 1, and the bending structure 5 is rotated and installed with an adjustment structure 7;

[0062] The pressing structure 6 is arranged in the shape of a long rectangular plate, and the pressing structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com