Vertical conveyor with recyclable mother trays

A vertical conveyor, circulating technology, used in transportation and packaging, lifting devices, lifting frames, etc., can solve the problems of car sinking, affecting high-frequency handling, impact on the position of the import and export of freight elevators, etc., to achieve convenient handling and operation. , Improve balance and facilitate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

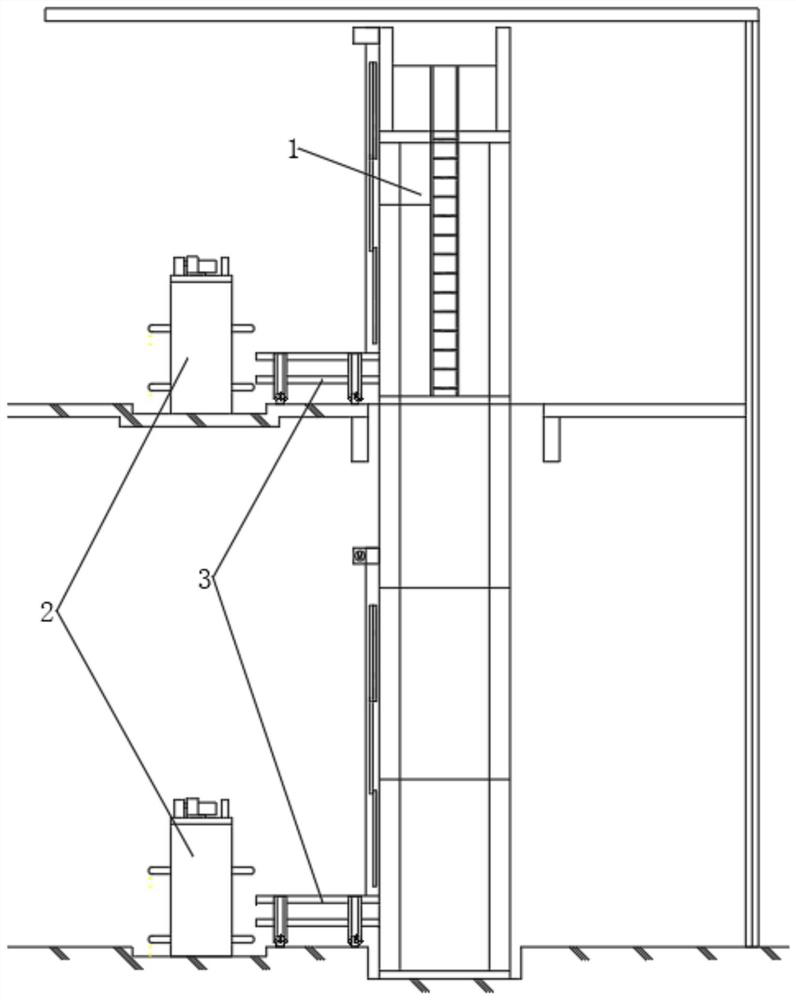

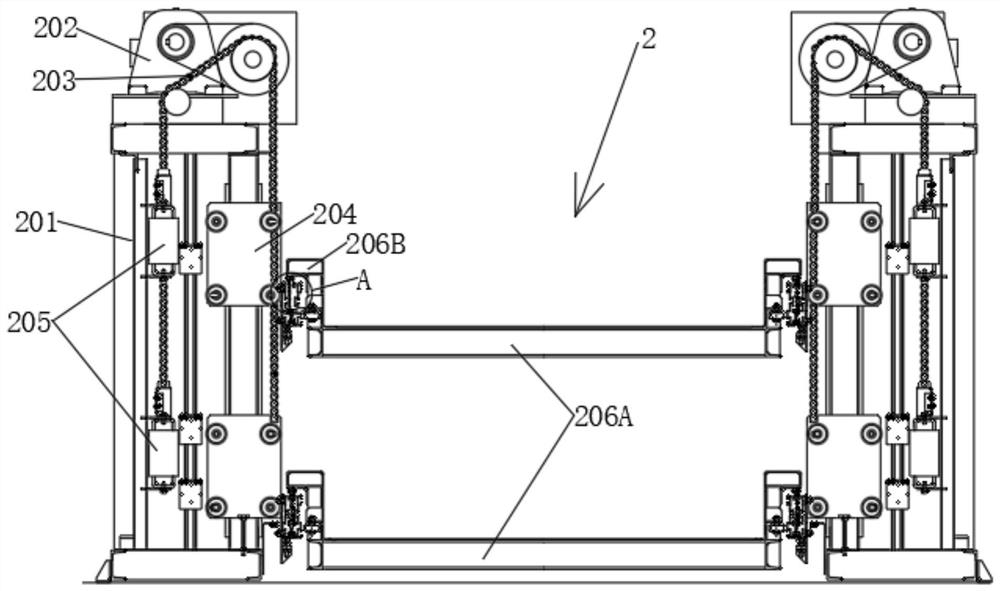

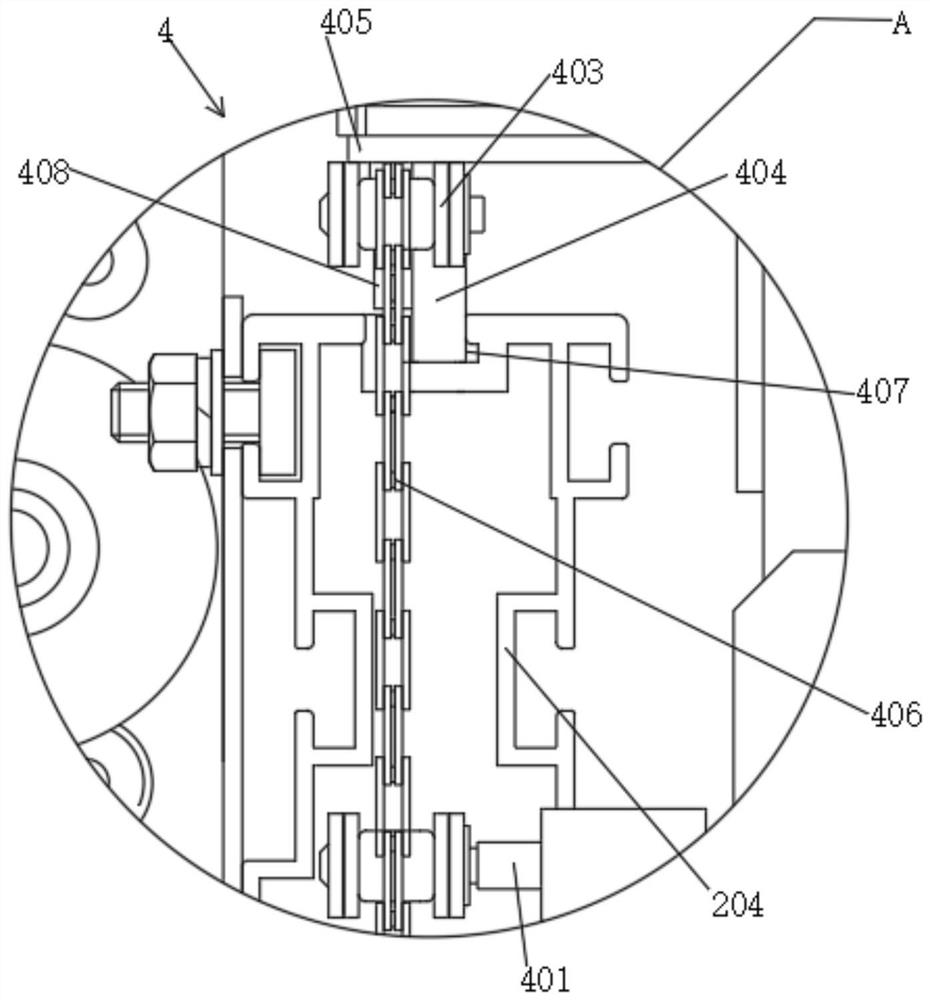

[0029] Embodiment 1 provides a recirculating vertical conveyor for mother trays. Embodiment 1 provides the connection and lifting device 2 provided by the present invention, which can vertically lift the special mother tray 206, lift and transport the articles to the transfer roller 303, and pass the transfer The drum 303 feeds the articles into the main body 1 of the device, which is convenient to carry and operate, and safe to use. The whole device does not include special equipment and does not need professional licensed personnel to operate. The balance device 205 is hung on the other end of the connection lifting chain 203, which can improve the balance of the special mother pallet 206 in the lifting process and the accuracy of the lifting height of the special mother pallet 206; The process of entering the device main body 1 is more stable and labor-saving. details as follows:

[0030] see Figure 1~5 , this embodiment provides a recyclable vertical conveyor for mother...

Embodiment 2

[0037] Embodiment 2 is an improvement on the basis of Embodiment 1. The special mother tray 206 provided in this embodiment is provided with a baffle plate 5, which can prevent articles, especially trucks, from falling from the special mother tray 206; further, by limiting the baffle plate 5 is rotatably connected with the special mother pallet 206 and configured with the latch 14 slot and the latch 14, the baffle plate 5 can be laid flat, and it is convenient to place goods in the special mother pallet 206 or the truck directly drives to the special mother pallet 206; further, by setting The return spring 15 can realize the precise return of the baffle plate 5 to its original position; furthermore, a pair of positioning sleeves 16 are provided to facilitate the positioning of the latch 14 .

[0038] details as follows:

[0039] see Figure 6-8 , the dedicated master tray 206 includes a tray portion 206A and a supporting portion 206B, the upper end surface of the tray portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com