High-yield bar production system

A production system and high-yield technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of high output, low investment cost, etc., and achieve great economic benefits, low comprehensive investment, and flexible production organization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

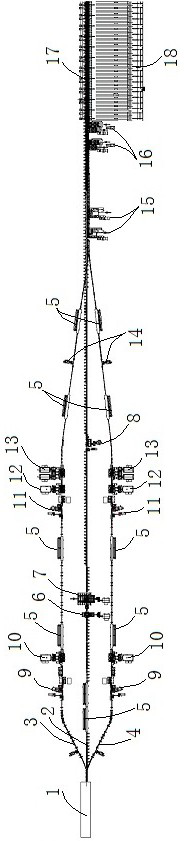

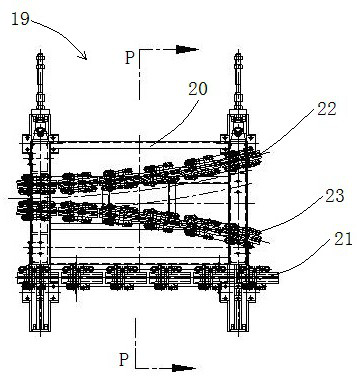

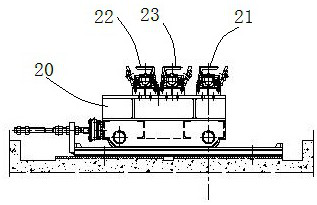

[0045] Further, between the rough, intermediate and pre-finishing areas 1 and the high-speed area, there are devices for connecting the pre-finishing area with the A-line production channel 2, the B-line production channel 3 and the C-line The traversing channel 19 of the channel 4 is produced. Furthermore, the traversing guide 19 includes a traversing trolley 20, an A-line transition guide 21 for connecting the pre-finishing area and the A-line production channel 2, and a transitional guide 21 for connecting the pre-finishing area and the A-line. The B-line transition channel 22 of the B-line production channel 3 and the C-line transition channel 23 for connecting the pre-finishing area and the C-line production channel 4; the A-line transition channel 21, the B-line transition channel Both the guide groove 22 and the C-line transition guide groove 23 are arranged on the traverse trolley 20 . The production system of this embodiment includes a rough rolling area, an intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com