Drying device with heating pretreatment function for white carbon black processing

A technology of heating pretreatment and drying equipment, which is applied in the direction of heating equipment, dryers for static materials, drying solid materials, etc., and can solve the problems of lack of convenient and fast feeding structure, affecting the efficiency of equipment use, and lack of drying structure. Achieve good dismantling, easy cleaning, and increase output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

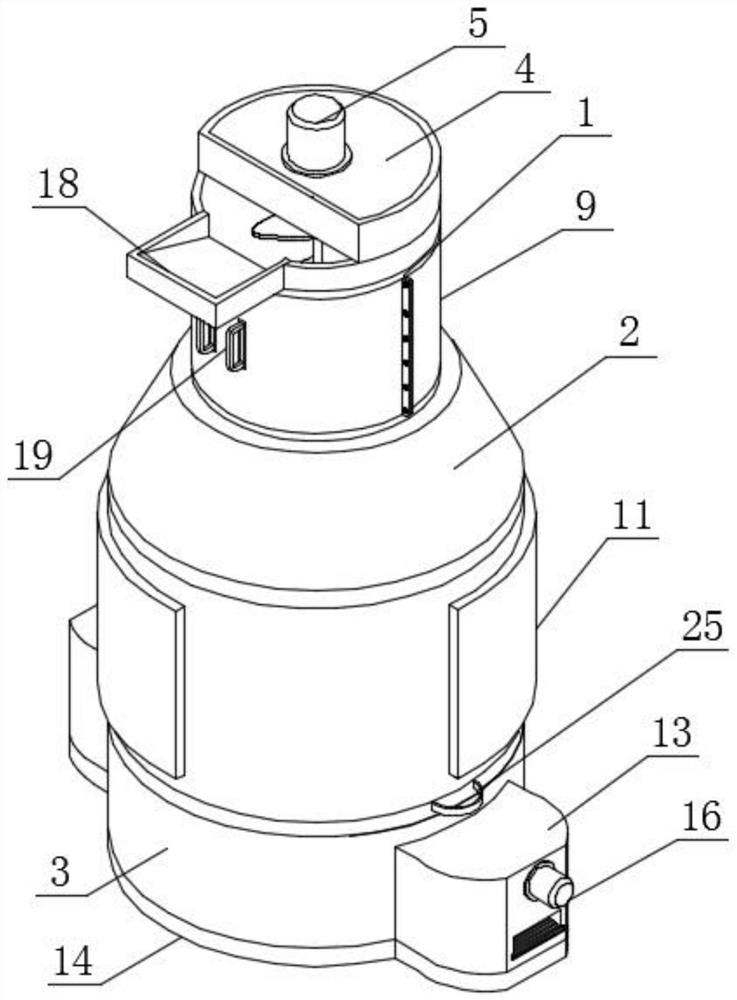

[0034] see figure 1 and figure 2 , an embodiment provided by the present invention, a drying device for silica processing with heating pretreatment, comprising a limit barrel 1, a limit seat 4, and a feed plate 18, the bottom of the limit barrel 1 is connected with Heating barrel 2, the bottom of heating barrel 2 is threaded with base 3, the top of limit barrel 1 is threaded with limit seat 4, the front of limit seat 4 is equipped with feed plate 18, and the outer surface of connecting plate 9 is set limited Position grip 19, positioning plate 20 is installed on both sides of connecting plate 9, drive motor 5 is installed on the top of limit seat 4, drive rod 6 is installed on the output end of drive motor 5, and the outer surface of drive rod 6 is provided with The stirring frame 7, the inner wall of the limiting barrel 1 is provided with a support frame 8, the outer surface of the limiting barrel 1 is fitted with an connecting plate 9, and the inner wall of the connecting ...

Embodiment 2

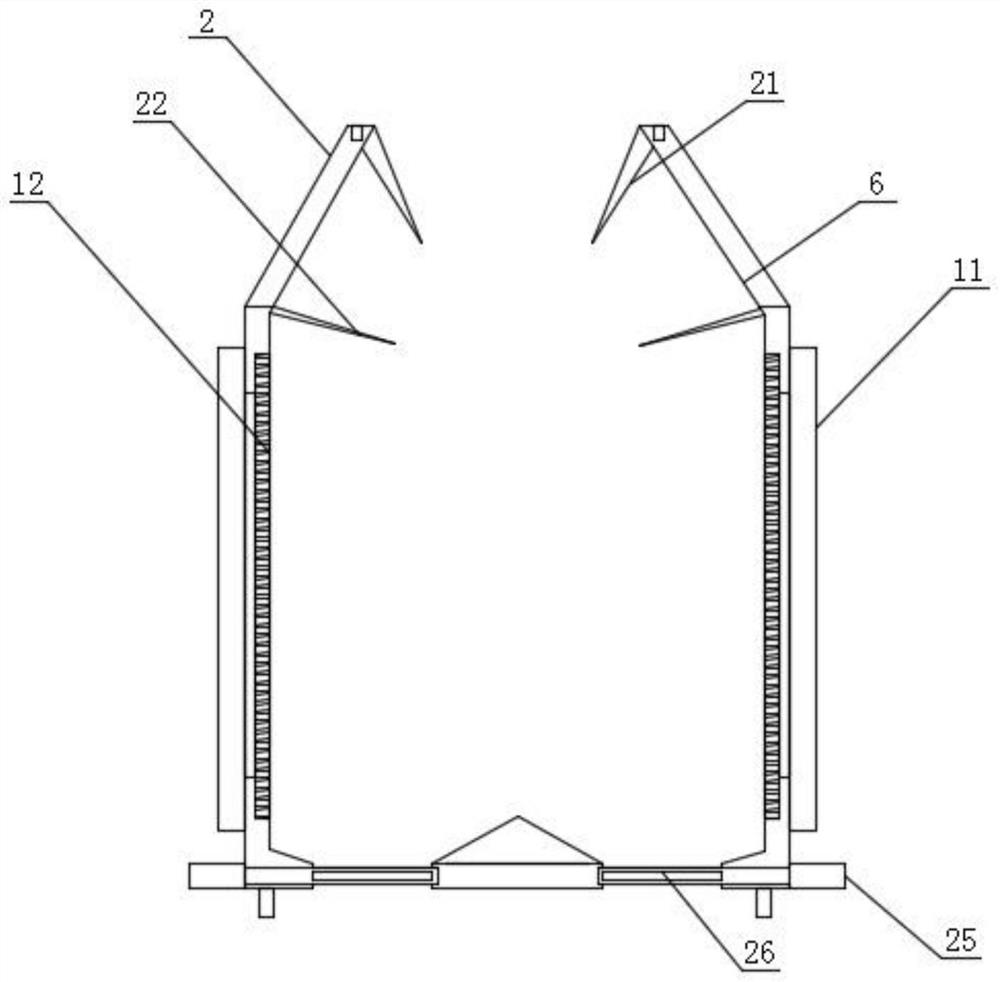

[0037] see figure 1 , image 3 and Figure 4, an embodiment provided by the present invention, a drying device for processing white carbon black with heating pretreatment, including a heating barrel 2, a power base 11 and a first current limiting sheet 21, the outer surface of the heating barrel 2 is provided with a Set the power base 11, the front end of the power base 11 is electrically connected to the electric heating plate 12, and the outer surface of the electric heating plate 12 is connected to the inner wall of the heating barrel 2, and the inner wall of the heating barrel 2 is sequentially installed with the first limiter from top to bottom. The flow plate 21 and the second current limiting plate 22, the bottom of the outer surface of the heating barrel 2 is connected with the limit handle 25, the inside of the heating barrel 2 is slidably connected with the sealing cover 26, and the outer surface of the sealing cover 26 is connected to the limit handle through the c...

Embodiment 3

[0040] see figure 1 , Figure 5 , Figure 6 and Figure 7 , an embodiment provided by the present invention, a drying device for silica processing with heating pretreatment, including a base 3, a discharge seat 13 and a limit handle 25, both sides of the base 3 are installed with The bottom of the discharge seat 13, the base 3 and the discharge seat 13 are all equipped with a limit base 14, the middle part of the bottom of the limit base 14 is fitted with a counterweight 23, and the outer side of the limit base 14 bottom is provided with an anti-skid ring 24 , the inner bottom wall of the base 3 is equipped with a flow-limiting seat 15, a stepper motor 16 is installed on the outside of the discharge seat 13, and a screw feeder 17 is installed on the output end of the stepper motor 16, and the front end of the screw feeder 17 Connected to the inside of the current limiting seat 15 through the bearing seat, the inner bottom wall of the discharge seat 13 is equipped with a ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com