Zero-dimensional ZnSe-one-dimensional FeSe2 heterojunction catalyst as well as preparation method and application thereof

A heterojunction and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low internal carrier separation and transmission efficiency, large band gap, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1g Zn(CH 3 COO) 2 2H 2 O, 1g SeO 2 , 2g sodium cetylbenzenesulfonate, 6g hydrazine hydrate, and 50g water are mixed according to the mass ratio of 1:1:2:6:50, and placed in a hydrothermal reaction kettle for hydrothermal reaction; the hydrothermal reaction temperature is 160°C , the constant temperature time is 12 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed alternately with deionized water and alcohol for 3 times, and then dried at 70°C for 4 hours; the dried product is ground into powder to obtain zero-dimensional nano-particle ZnSe; the above 10g zero-dimensional nano-particle ZnSe, 1g FeCl 3 , 2g Na 2 SeO 3 , 4g of cetyltrimethylammonium bromide, 4g of hydrazine hydrate and 50g of water are mixed according to the mass ratio of 10:1:2:4:4:50 to form a precursor solution, which is placed in a hydrothermal reaction kettle for hyd...

Embodiment 2

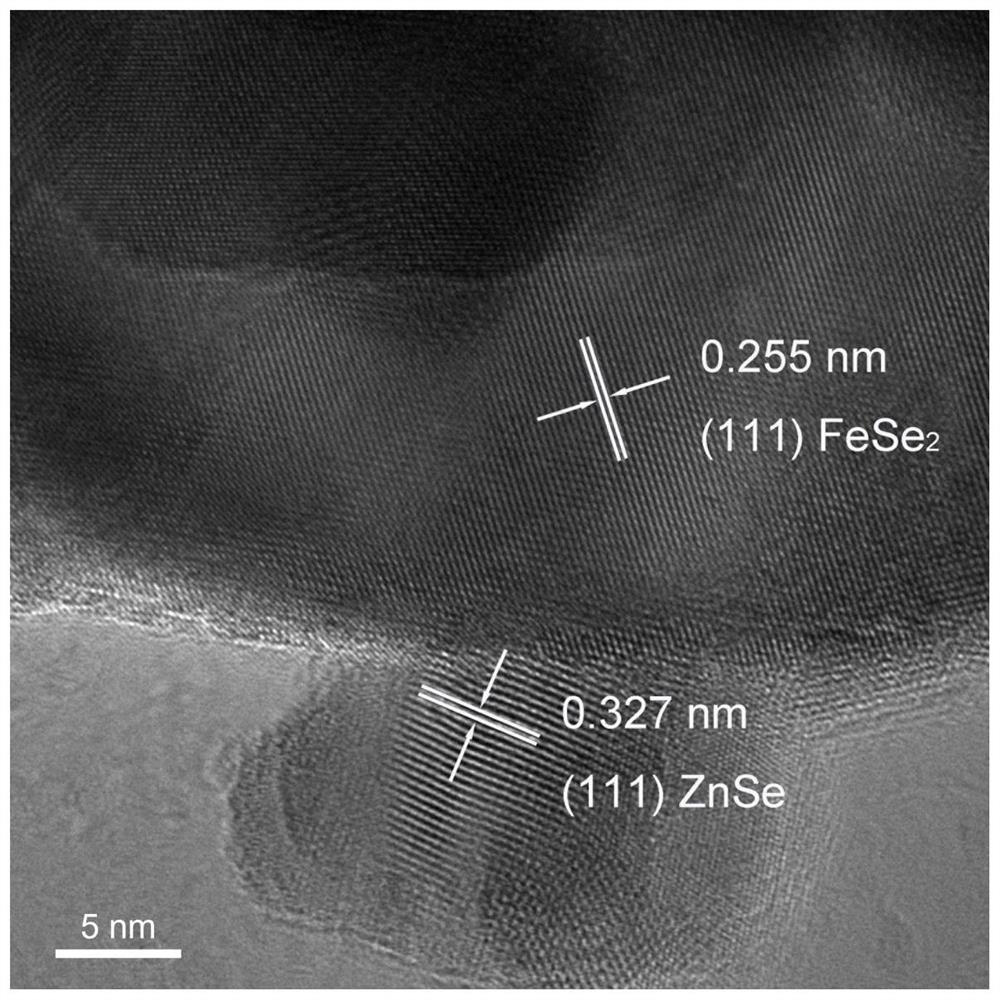

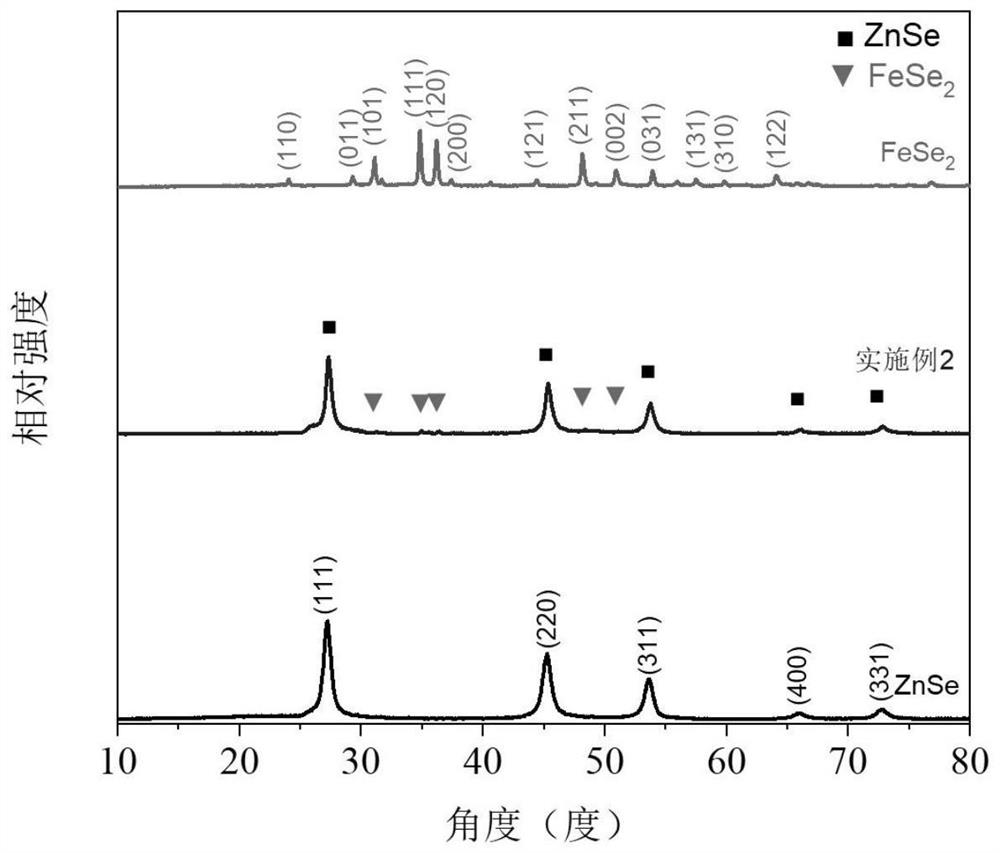

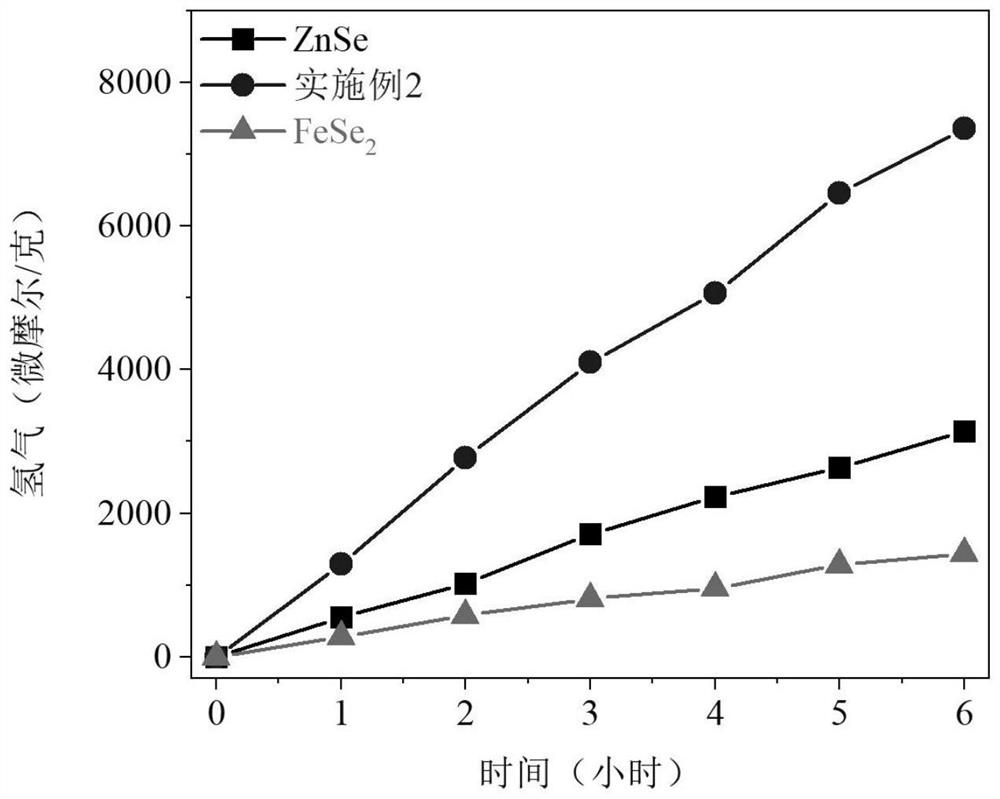

[0032] 1g Zn(CH 3 COO) 2 2H 2 O, 1g SeO 2 , 3g of sodium cetylbenzenesulfonate, 8g of hydrazine hydrate, and 50g of water are mixed according to the mass ratio of 1:1:3:8:50, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 180°C , the constant temperature time is 14 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed alternately with deionized water and alcohol for 3 times, and then dried at 80°C for 5 hours; the dried product is ground into powder to obtain zero-dimensional nano-particle ZnSe; the above 10g zero-dimensional nano-particle ZnSe, 2g FeCl 3 , 3g Na 2 SeO 3 , 5g of cetyltrimethylammonium bromide, 6g of hydrazine hydrate and 50g of water are mixed according to the mass ratio of 10:2:3:5:6:50 to form a precursor solution, which is placed in a hydrothermal reaction kettl...

Embodiment 3

[0038] 1g Zn(CH 3 COO) 2 2H 2 O, 2g SeO 2 , 4g sodium cetylbenzenesulfonate, 10g hydrazine hydrate, and 50g water are mixed according to the mass ratio of 1:2:4:10:50, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 200°C , the constant temperature time is 16 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed alternately with deionized water and alcohol for 3 times, and then dried at 80°C for 6 hours; the dried product is ground into powder to obtain zero-dimensional nano-particle ZnSe; the above 10g zero-dimensional nano-particle ZnSe, 2g FeCl 3 , 4g Na 2 SeO 3 , 6g of cetyltrimethylammonium bromide, 8g of hydrazine hydrate and 50g of water are mixed according to the mass ratio of 10:2:4:6:8:50 to form a precursor solution, which is placed in a hydrothermal reaction kettle for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com