Quality inspection detection device for flywheel housing inner cavity size

A detection device and flywheel housing technology, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of flywheel housing movement, low quality inspection efficiency, narrow use range, etc., to expand the fixed range and test accuracy. High, improve the effect of quality inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

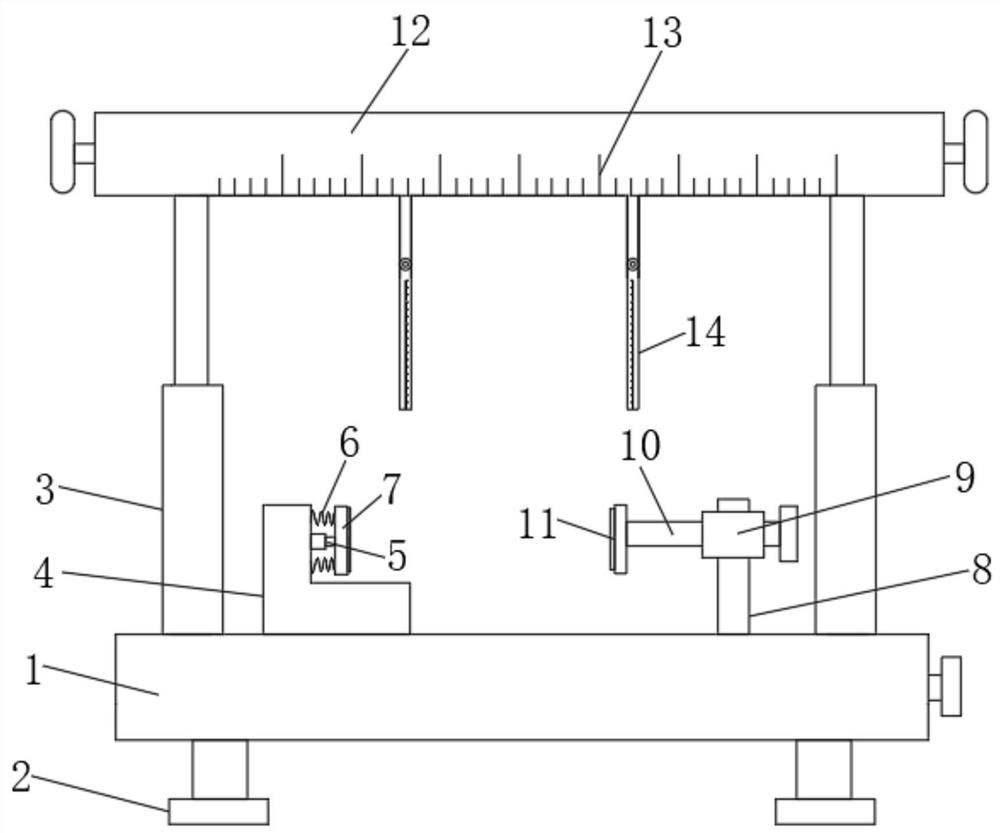

[0027] See Figure 1 ~ 4 , A quality inspection detection device for the inner cavity of the flywheel housing, including

[0028] The base 1 is fixed to the lower surface of the lower surface, and the upper surfaces thereof are attached to the upper surface, and the upper end of the lifting mechanism 3 is fixed to the upper end of the lifting mechanism 3;

[0029] The translation mechanism is disposed within the pass groove disposed inside the horizontal support column 12, and its symmetry is provided;

[0030] Combined clamping mechanism, it is disposed between the upper surface of the base 1 between the two lifting mechanisms 3, which is convenient to fix the flywheel housing by setting the combined clamping mechanism to avoid moving during measurement;

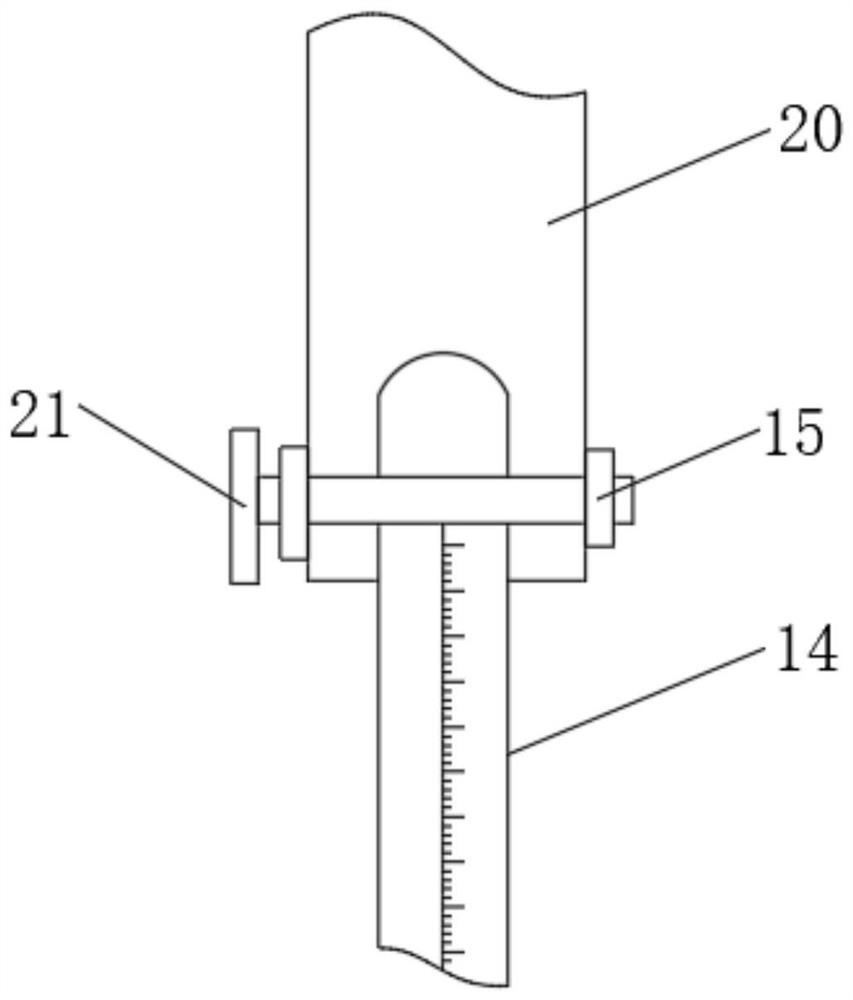

[0031] The scale 14 is provided at the lower end of the translation mechanism, and is convenient to measurement of the inner cavity of the flywheel housing by setting the scale 14.

[0032] In an embodiment of the present invent...

Embodiment 2

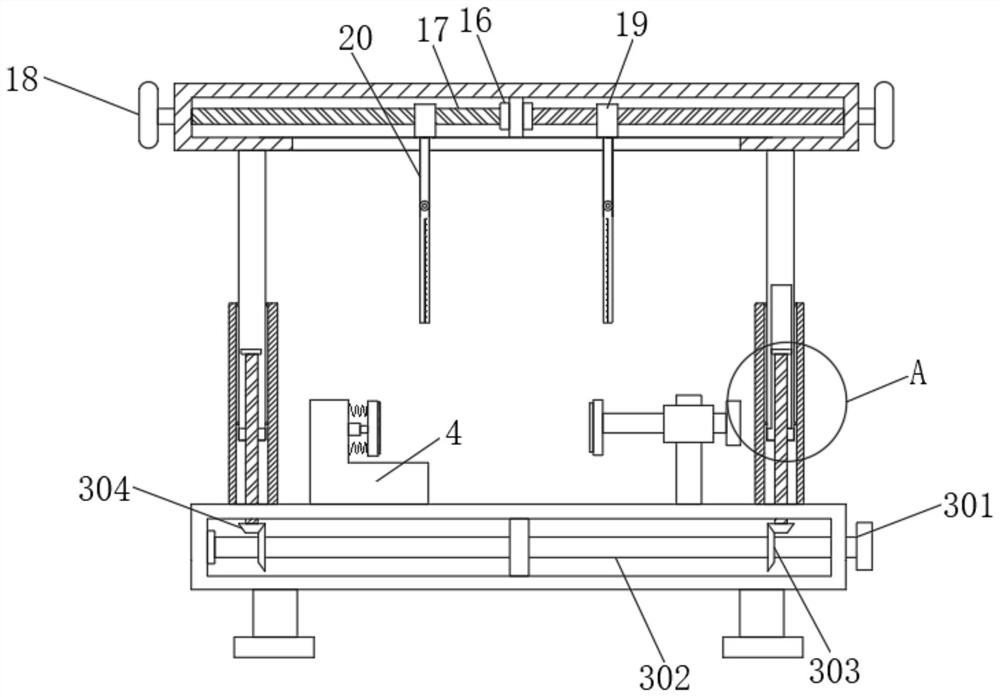

[0035] See Figure 1 ~ 4 , A quality inspection detection device for the inner cavity of the flywheel housing, including

[0036] The base 1 is fixed to the lower surface of the lower surface, and the upper surfaces thereof are attached to the upper surface, and the upper end of the lifting mechanism 3 is fixed to the upper end of the lifting mechanism 3;

[0037] The translation mechanism is disposed within the pass groove disposed inside the horizontal support column 12, and its symmetry is provided;

[0038] Combined clamping mechanism, it is disposed between the upper surface of the base 1 between the two lifting mechanisms 3, which is convenient to fix the flywheel housing by setting the combined clamping mechanism to avoid moving during measurement;

[0039] The scale 14 is provided at the lower end of the translation mechanism, and is convenient to measurement of the inner cavity of the flywheel housing by setting the scale 14.

[0040] In the embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com