Waste heat recycling device with flue gas purification mechanism

A waste heat recovery and flue gas purification technology, applied in the direction of clean heat transfer devices, indirect heat exchangers, heat exchanger types, etc., can solve the problems of heat exchange efficiency reduction, pollution, environmental pollution, etc., and achieve loss reduction and use The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

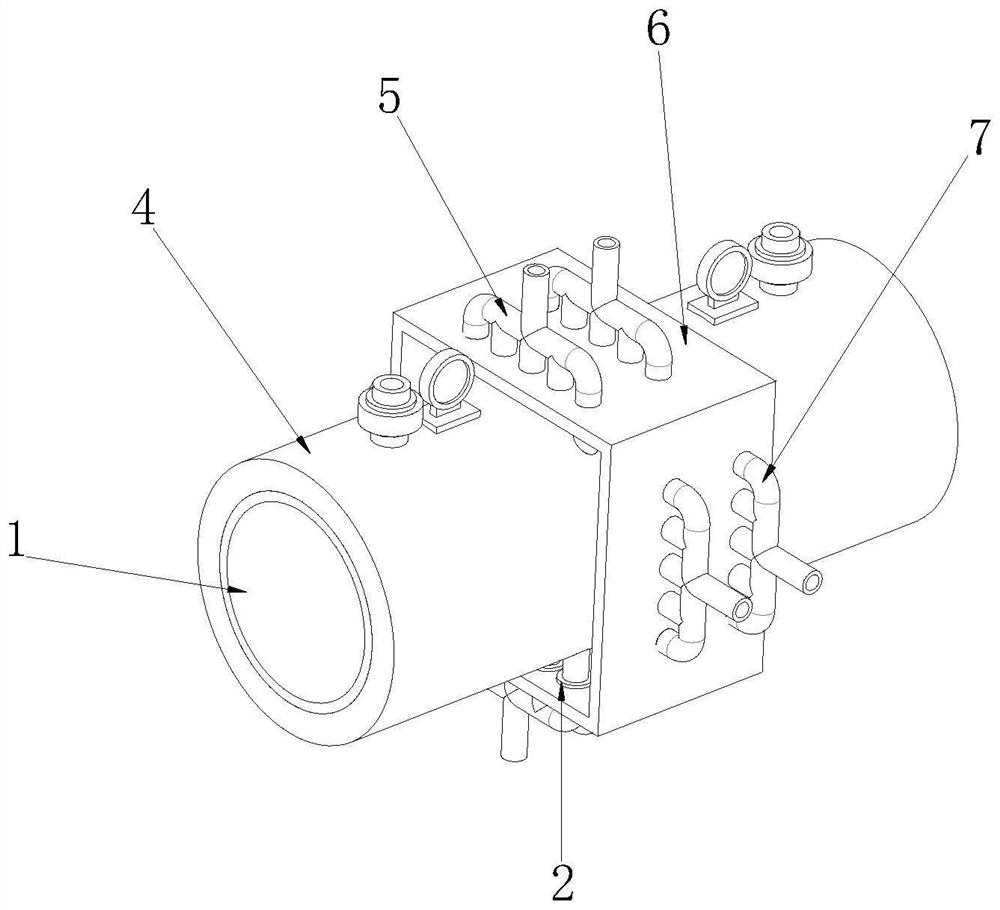

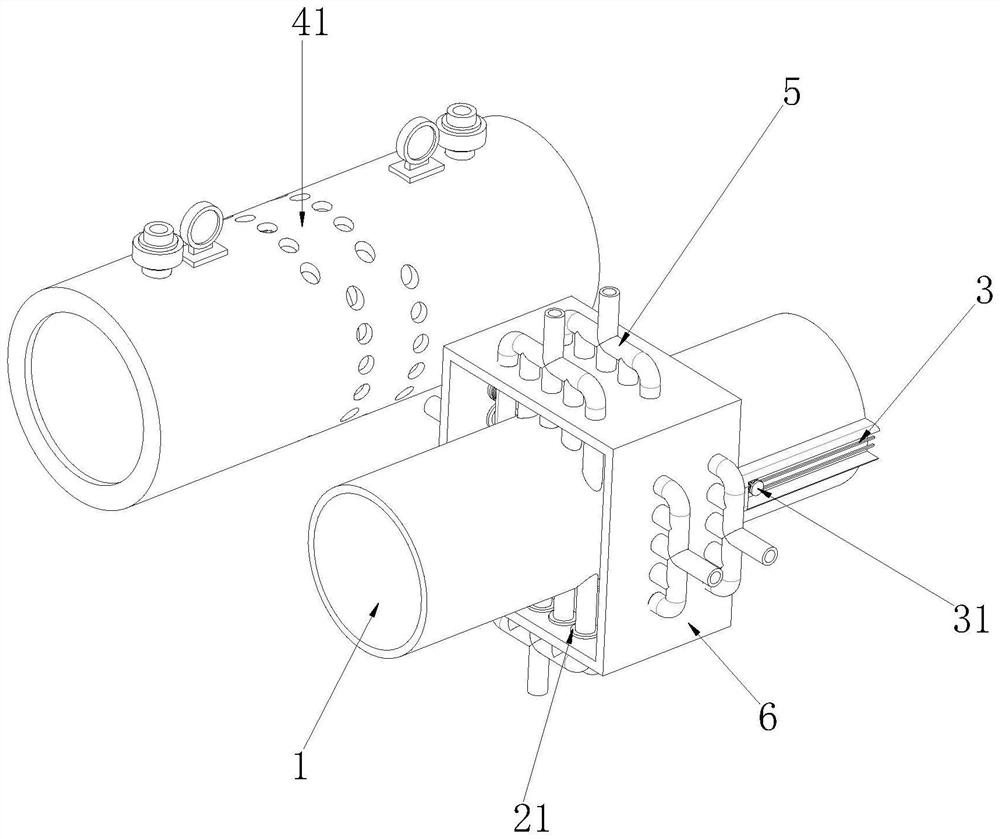

[0041] see Figure 1-7 As shown, the waste heat recovery and utilization device with a flue gas purification mechanism includes a smoke exhaust pipe 1, a longitudinal recovery pipe 5, an outer frame 6 and a horizontal recovery pipe 7, and the upper and lower sides of the outer surface of the smoke exhaust pipe 1 are connected with longitudinal recovery pipes 5 , the left and right sides of the outer surface of the smoke exhaust pipe 1 are connected with horizontal recovery pipes 7, and the outer wall of the smoke exhaust pipe 1 is provided with an outer frame 6 at the position corresponding to the longitudinal recovery pipe 5 and the horizontal recovery pipe 7;

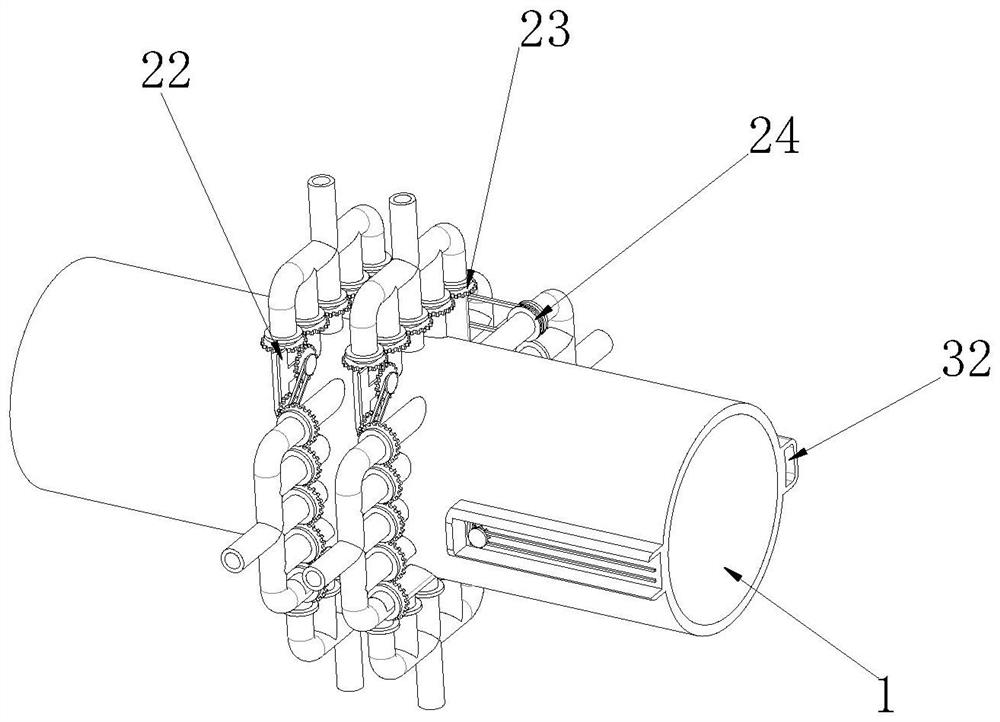

[0042] A waste heat recovery mechanism 2 is provided inside the outer frame 6 corresponding to the position of the exhaust pipe 1. The waste heat recovery mechanism 2 includes a rotating tube 216, and the two ends of the rotating tube 216 are rotatably connected with a rotating sleeve 21. Both ends of the rotating tube...

Embodiment 2

[0046] see figure 2 , Figure 4 and Figure 7-11As shown, the ash removal mechanism 3 is arranged on the outer side wall of the exhaust pipe 1 close to the outer frame 6. The ash removal mechanism 3 includes a transmission chamber 32, and the inner side wall of the transmission chamber 32 is connected to the position corresponding to the third runner 215 through a rotating shaft. There is a fourth runner 34, and the fourth runner 34 is connected to the third runner 215 through a transmission belt 25. The fourth runner 34 is connected to a fourth gear 35 on one side of the outer wall, and the inner wall of the transmission chamber 32 is close to the fourth gear 35. The position is connected with the fifth gear 33 through the rotation of the rotating shaft, the fourth gear 35 and the fifth gear 33 are perpendicular to each other and interfitted with each other, and are driven to rotate, and the fifth gear 33 is connected to the fifth runner 31 on one side of the outer wall. T...

Embodiment 3

[0050] see Figure 8 and Figure 12 As shown, the end of the smoke exhaust pipe 1 away from the outer frame 6 is provided with an auxiliary mechanism 4, the auxiliary mechanism 4 includes a catalytic bed 44, and the outer wall of the connecting pipe on the side of the catalytic bed 44 close to the smoke exhaust pipe 1 is connected with a communication valve 42. An exhaust gas quality detector 45 is connected to the outer wall of the connecting pipe on the side of the bed 44 away from the smoke exhaust pipe 1, and an air collecting hopper 46 is connected to one end of the connecting pipe on the side of the catalytic bed 44 away from the smoke exhaust pipe 1, and the gas collecting hopper 46 is far away from the One side of the catalytic bed 44 is connected to a desulfurization box 47 through a connecting pipe. The interior of the desulfurization box 47 reacts with the sulfur oxides in the flue gas through the lime milk solution to remove the sulfur oxides. The outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com