Two-dimensional precise anti-backlash adjusting mechanism of photoelectric autocollimator

A photoelectric autocollimator and adjustment mechanism technology, applied in the direction of supporting machines, mechanical equipment, machine/stands, etc., can solve the problems of moving out of the measurement range, jumping and empty distance, and high measurement accuracy, avoiding measurement data coupling, Easy to install and operate, improve the effect of adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

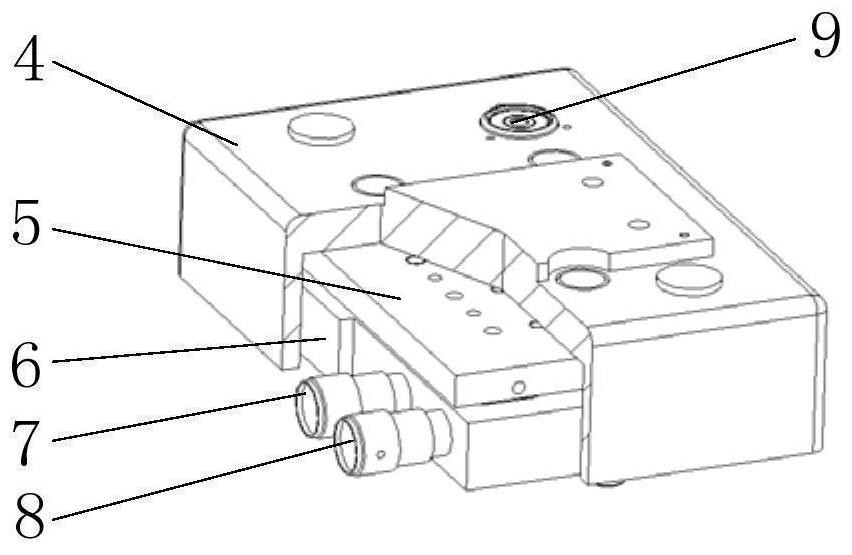

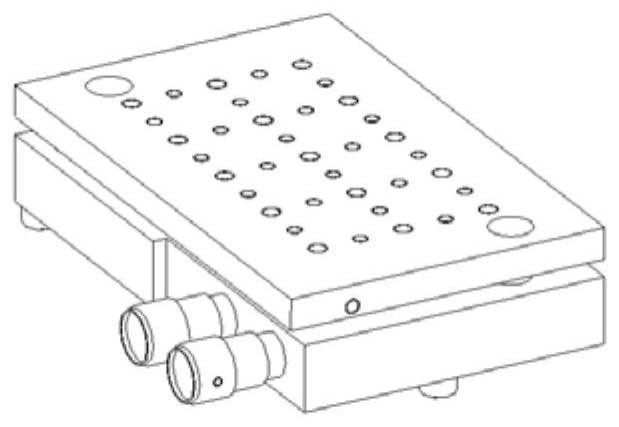

[0037] This embodiment provides a photoelectric autocollimator two-dimensional precision anti-backlash adjustment mechanism, see the attached Figure 1-2 , the adjustment mechanism 3 includes: an upper plate 5, a lower plate 6, a rotating shaft 28, a top column 29, a pressure cap 31, an azimuth component, a pitch component, an anti-backlash component, an adapter seat 4 and a level 9;

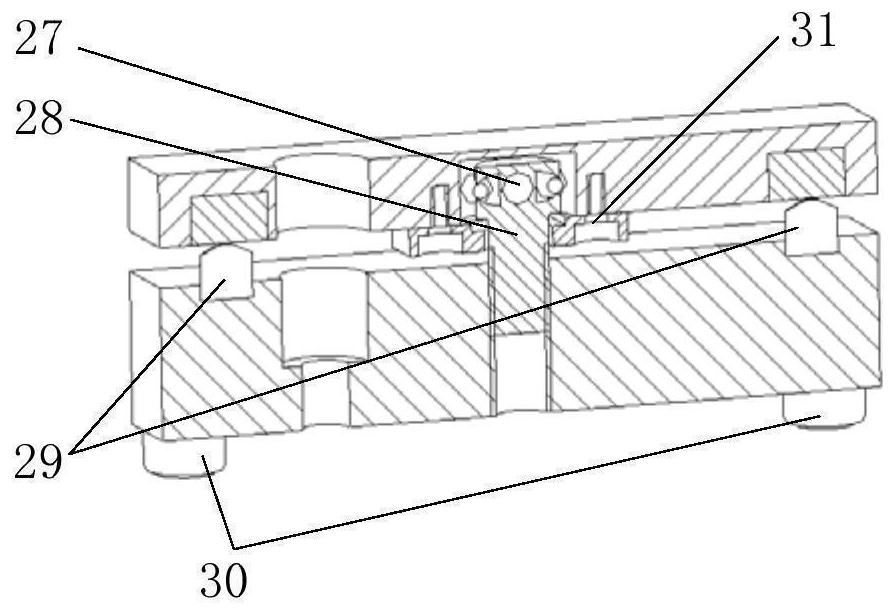

[0038] See attached image 3 , the lower surface of the lower plate 6 is provided with a bottom foot 30 for supporting on the external platform, and the upper surface of the lower plate 6 is fixed with two top posts 29, and the upper ends of the top posts 29 are processed as arc surfaces; The upper plate 5 is placed on the lower plate 6 and supported on the top column 29, that is, the lower surface of the upper plate 5 is in contact with the arc surface of the top column 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com