Super high-rise post-cast floor steel bar reserved formwork and construction method thereof

A technology of super high-rise and steel formwork, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the impact of overall pouring strength, gluten and bottom Ribs are easy to fit, construction personnel are inconvenient, etc., to ensure the quality of pouring construction and the overall economic benefits of construction, fixed and reliable, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

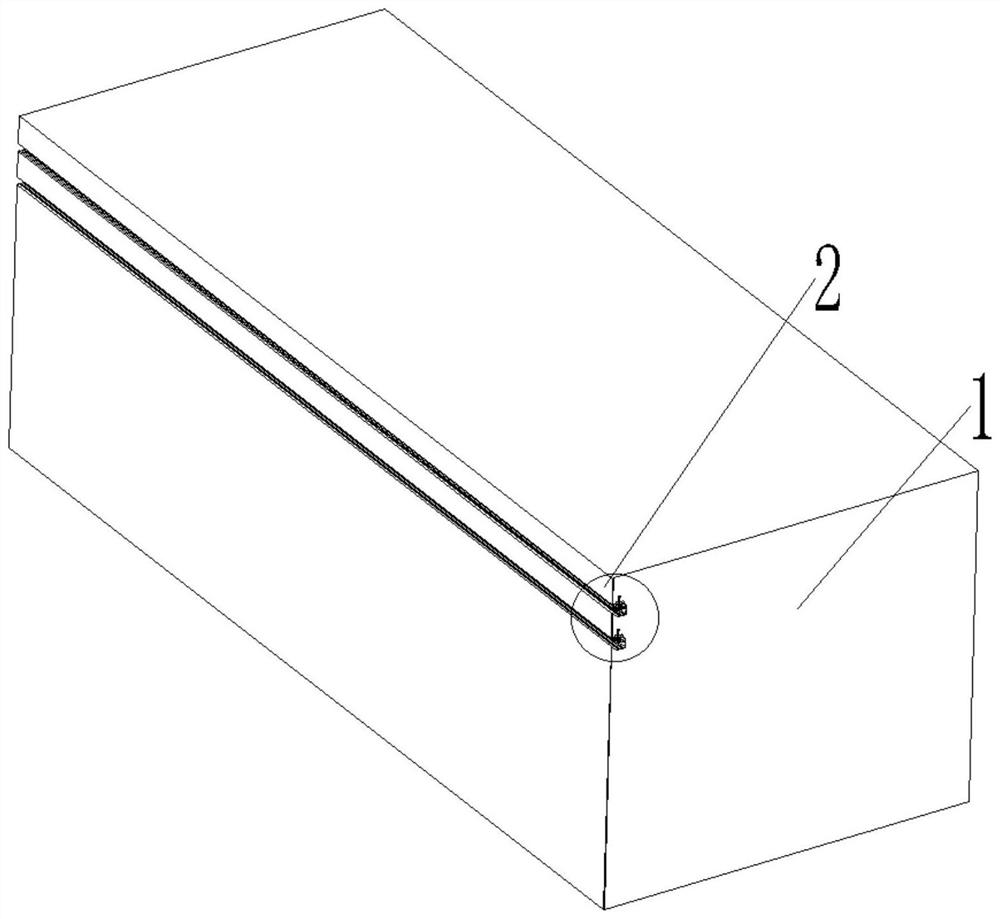

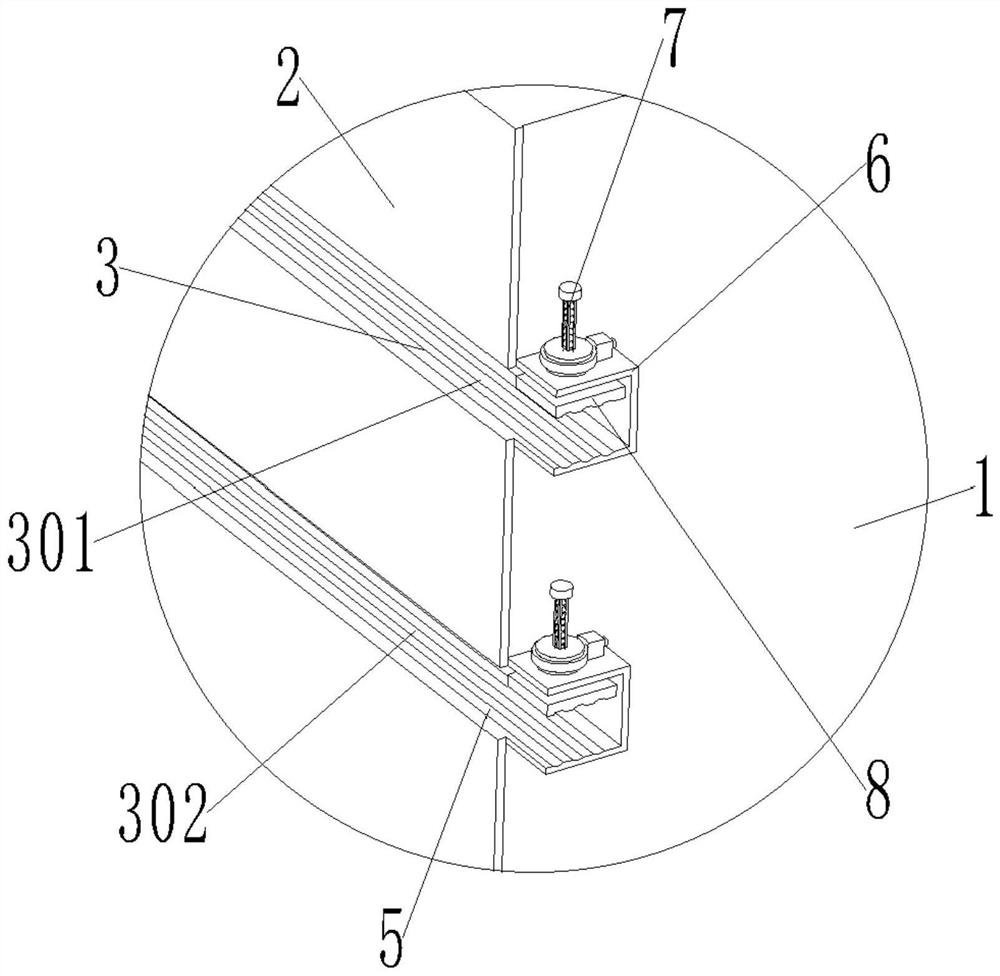

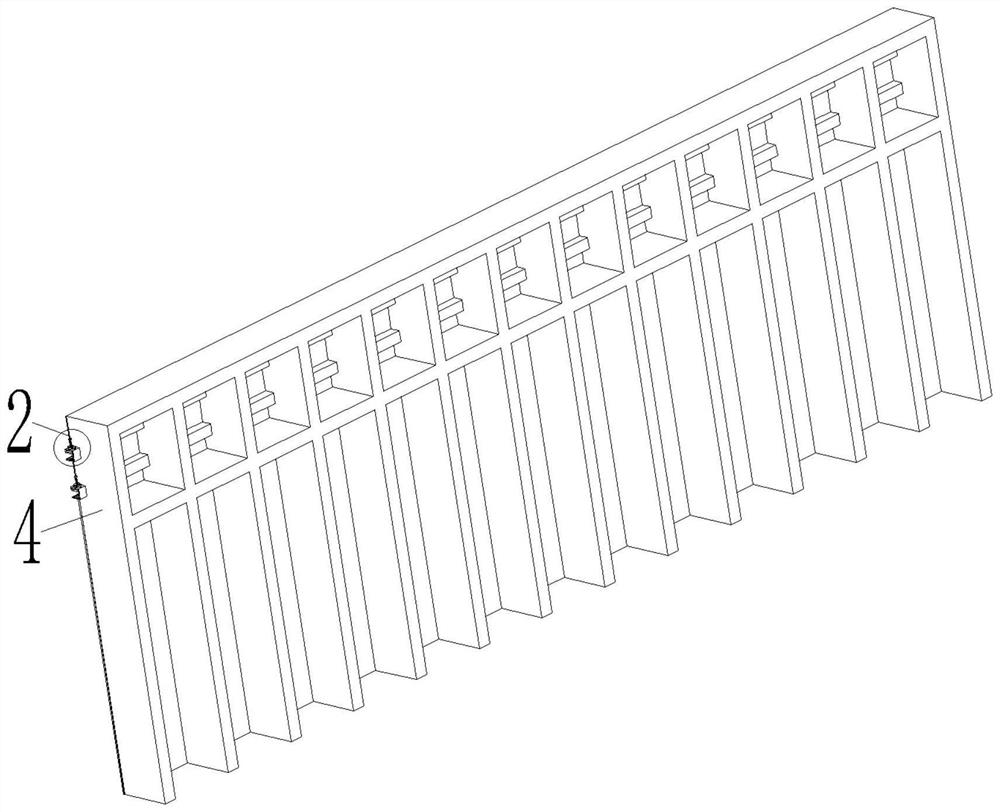

[0033] see Figure 1 to Figure 9 , the present invention provides a technical solution: a super-high-rise post-cast floor reinforcement reserved formwork, the present invention includes a core tube shear wall 1, a steel formwork 2, a double groove 3, a formwork secondary keel 4 and a concave fixing plate 6, Active rod 7, pressing plate 8, positioning assembly 10, clamping assembly 11;

[0034] One side of the core tube shear wall 1 is fixed with a formwork sub-keel 4, and one side of the formwork sub-keel 4 is fixed with a steel formwork 2. The steel formwork 2 is provided with double grooves 3, and the double grooves 3 are equidistantly arranged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com