Rapid copper wire cutting device

A rapid cutting and copper wire technology, applied in the field of copper wire cutting, can solve the problems of low copper wire cost, low efficiency, cutting efficiency affected by tools, etc., and achieve the effect of ensuring cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

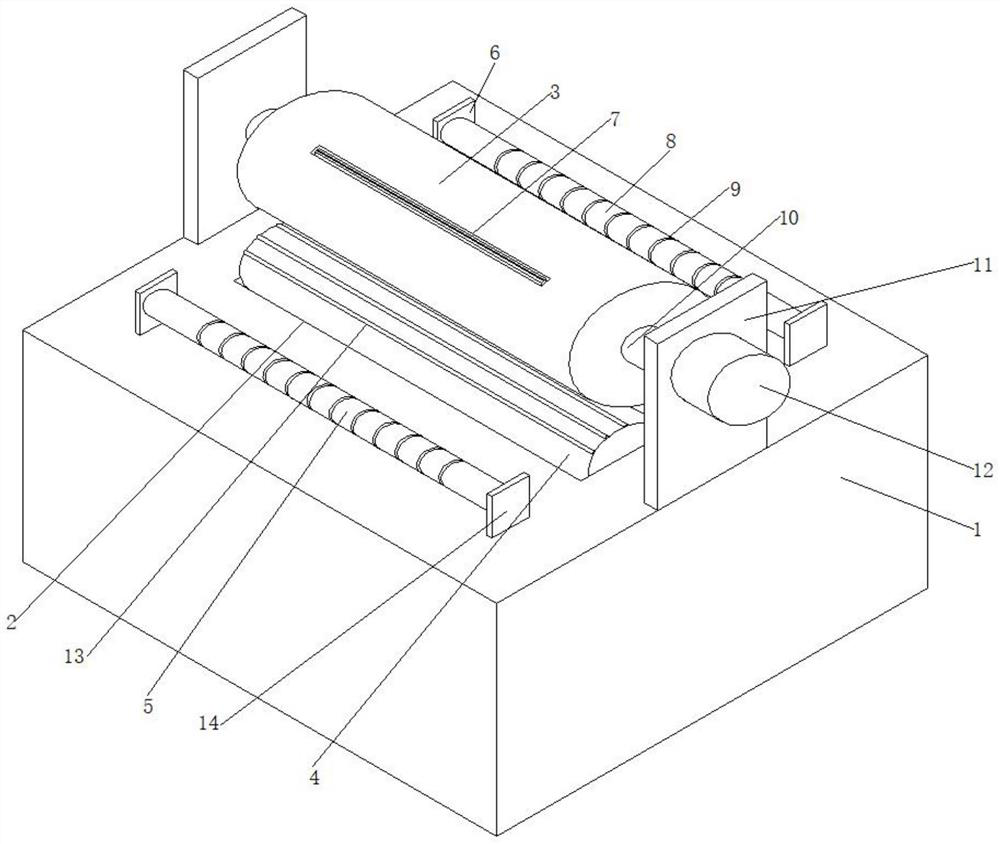

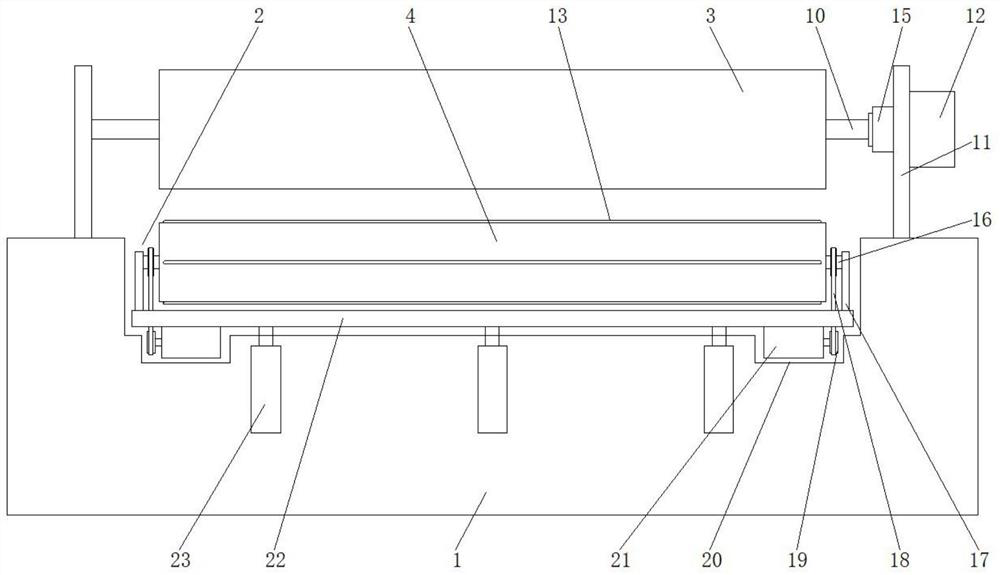

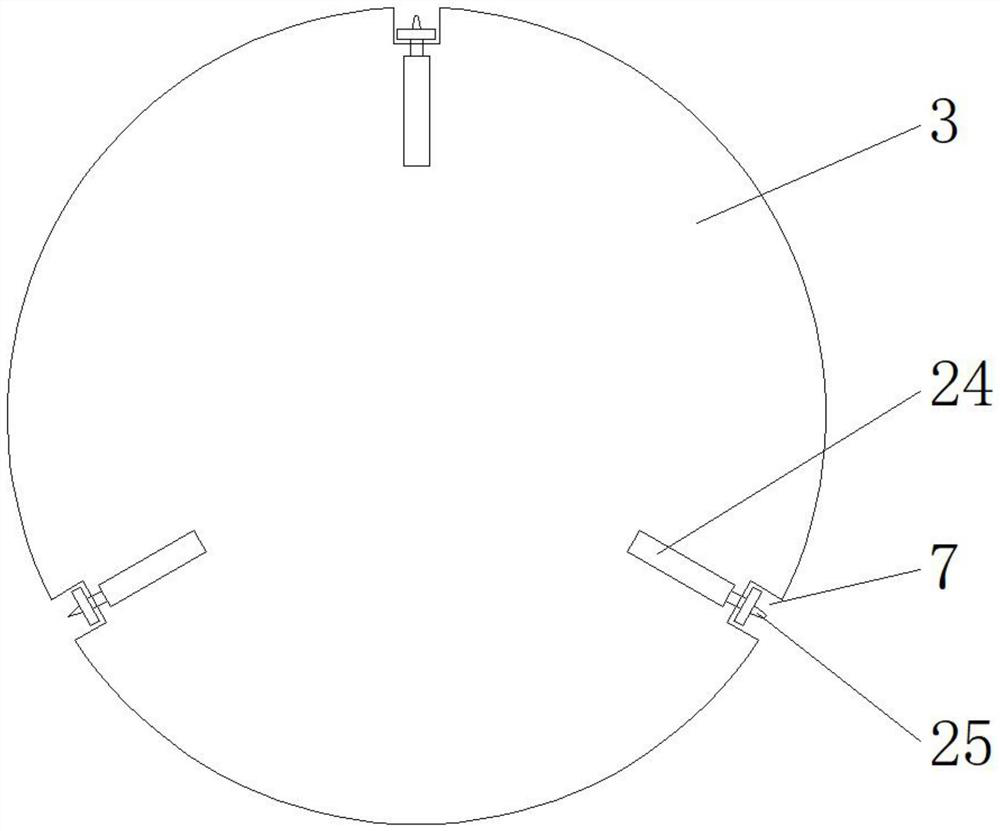

[0027] see Figure 1-4 , the present invention provides a technical solution: a copper wire rapid cutting device, including a support 1, a roller groove 2, an upper roller 3, a lower roller 4 and a leading roller 5; the roller groove 2 is arranged laterally on the support 1, and the roller groove 2 is located laterally in the middle of the surface of the support 1;

[0028] A lifting plate 22 is arranged horizontally below the inside of the roller groove 2, and the lifting plate 22 is parallel to the bottom of the roller groove 2. A first electric push rod 23 is vertically embedded in the support 1 below the lifting plate 22. There are three push rods 23, and the top of the first electric push rod 23 is fixed on the lower surface of the lifting plate 22, and the two sides of the surface of the lifting plate 22 are vertically fixed with the second side plate 17, and the lower roller 4 passes through The second rotating rod 16 is rotatably installed between the second side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com