Backwind-preventing high-pressure-difference-resisting rotary feed valve

A rotary feeding valve and high-pressure-resistant technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of reducing the pressure of high-pressure pipelines, affecting normal feeding, and loose connections, etc., to avoid damage, Improve the transmission efficiency and greatly promote the effect of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

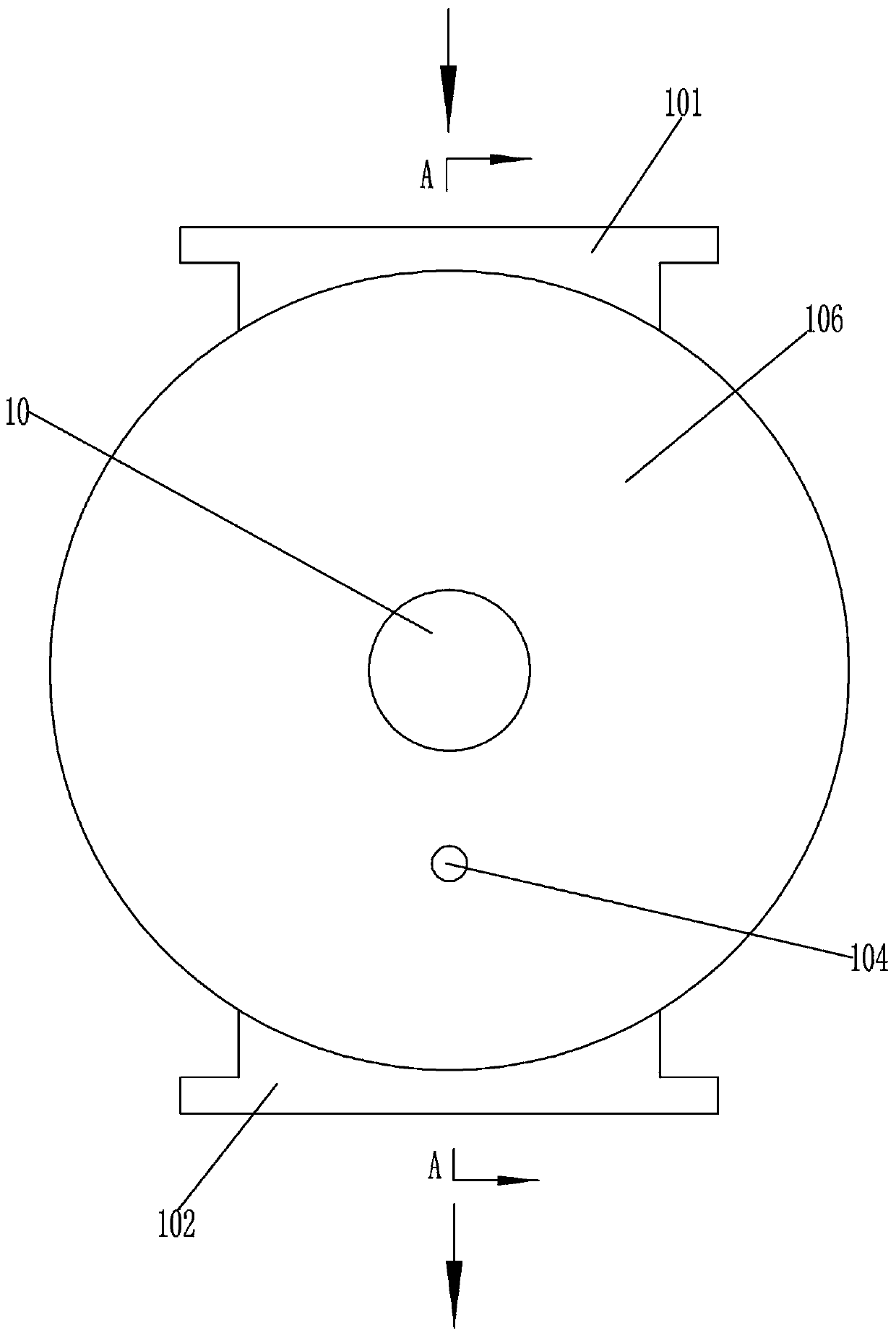

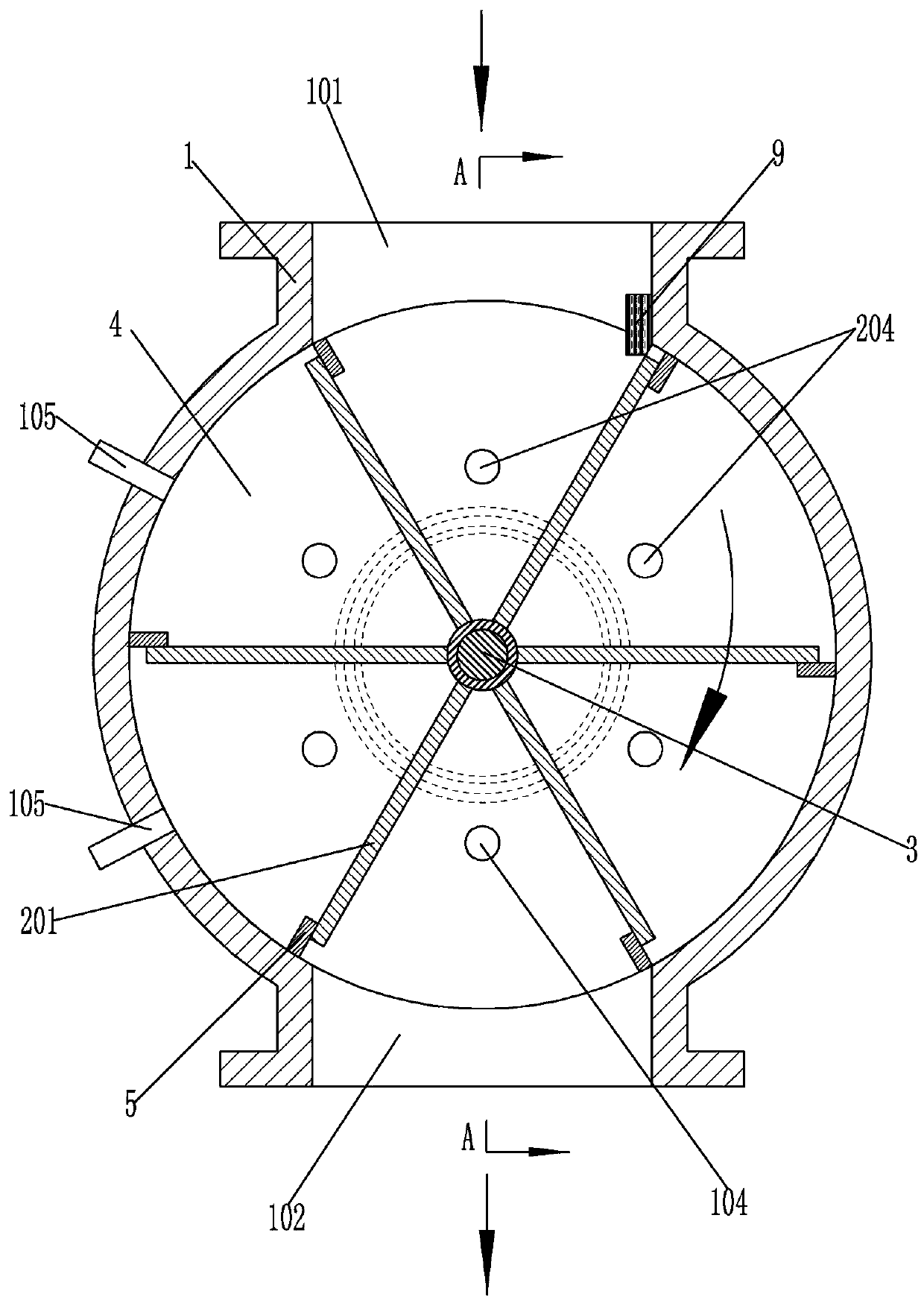

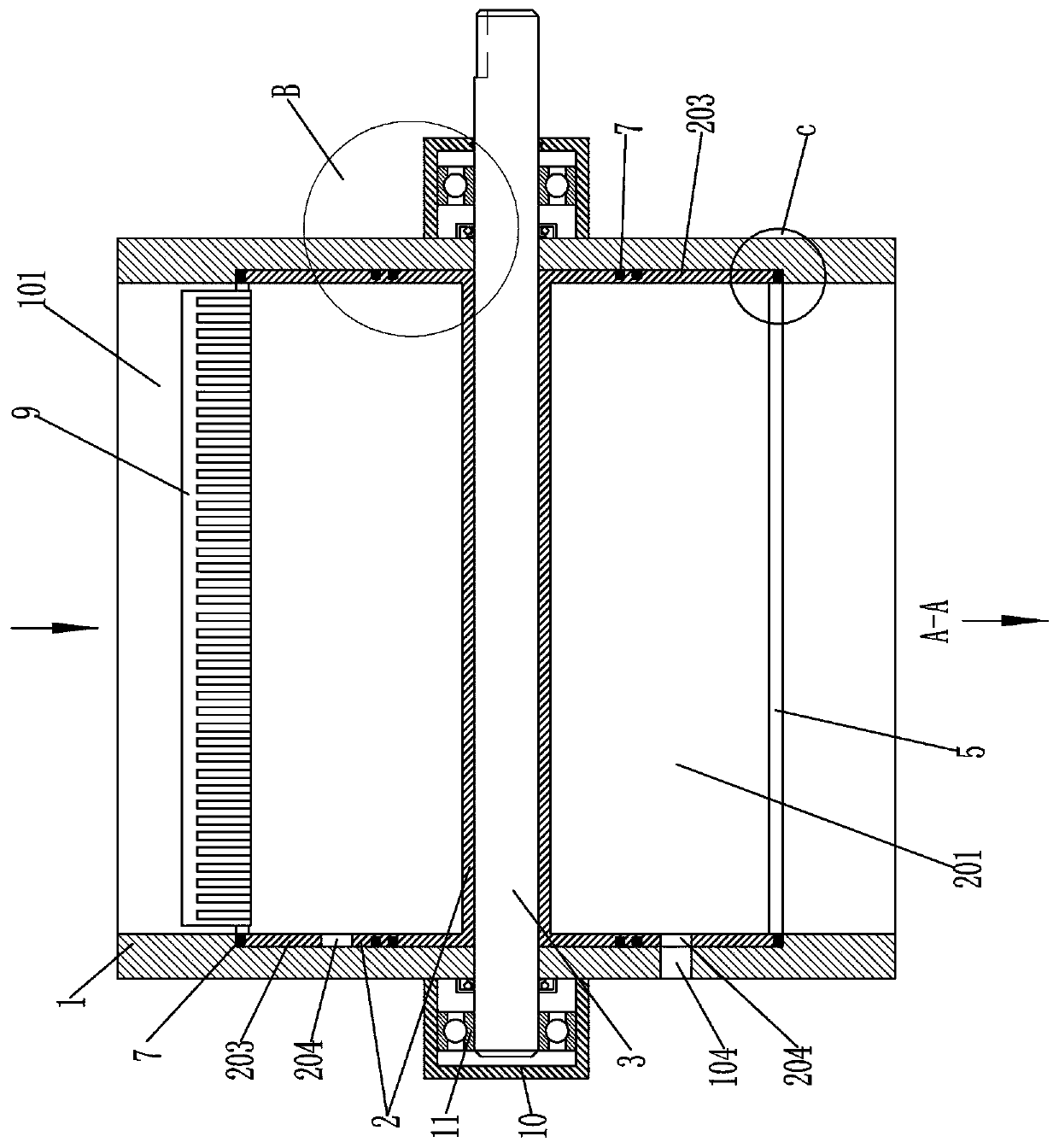

[0020] Embodiment 1, refer to the accompanying drawings (1-6) of the specification, a rotary feeding valve with anti-return wind and high pressure difference resistance, including a feeding valve housing, a rotating impeller, and a drive shaft, characterized in that: the feeding valve The upper end of the housing is provided with a material inlet, and the lower end is correspondingly opened with a material outlet. The center of the cover at both ends of the housing is provided with a shaft installation hole for installing the drive shaft. One of the shaft installation holes and the lower outlet There is a shell air supply hole in the middle of the end cover between the material holes. The shell air supply hole is externally connected with a high-pressure air source to introduce high-pressure gas into the shell. There are two symmetrical arc-shaped side walls on the empty side of the shell. The exhaust hole is used to discharge the high-pressure gas that the return air enters in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com