Meshing type soil crushing and mixing device for ex-situ soil remediation and treatment

A soil remediation and soil crushing technology, which is applied in the restoration of polluted soil, mixers, grain processing, etc., can solve the problems of reduced crushing and mixing efficiency, easy to block materials, etc., and achieve the effect of improving effect and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

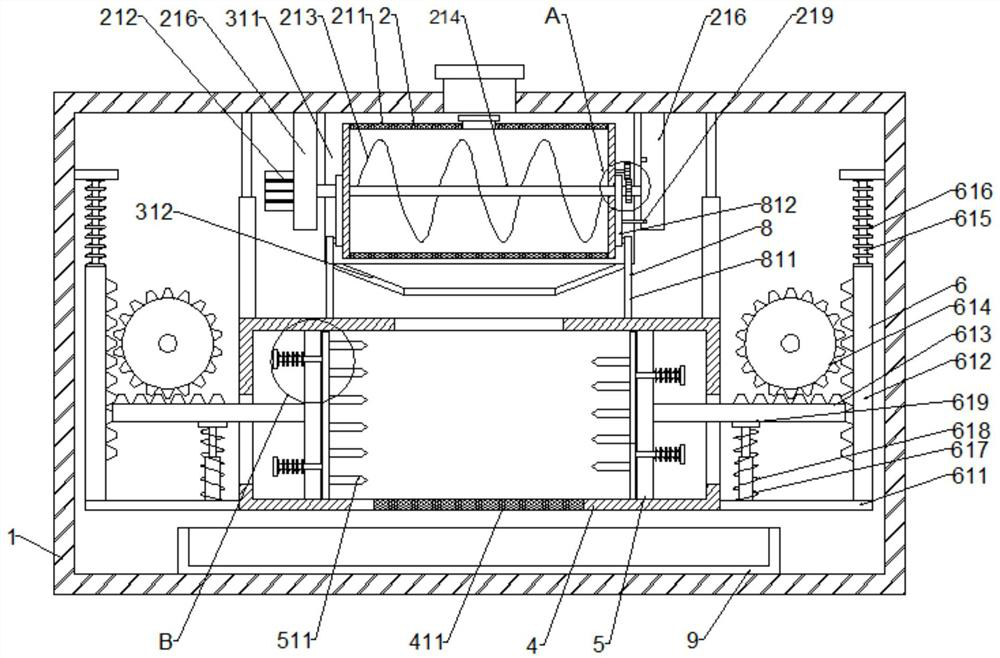

[0046] As an embodiment of the present invention, please refer to Figure 1 to Figure 2 : A soil pulverizing and mixing device for meshing heterotopic soil restoration and treatment, comprising a main body 1, and the main body 1 is correspondingly provided with a feed pipe 1, and also includes:

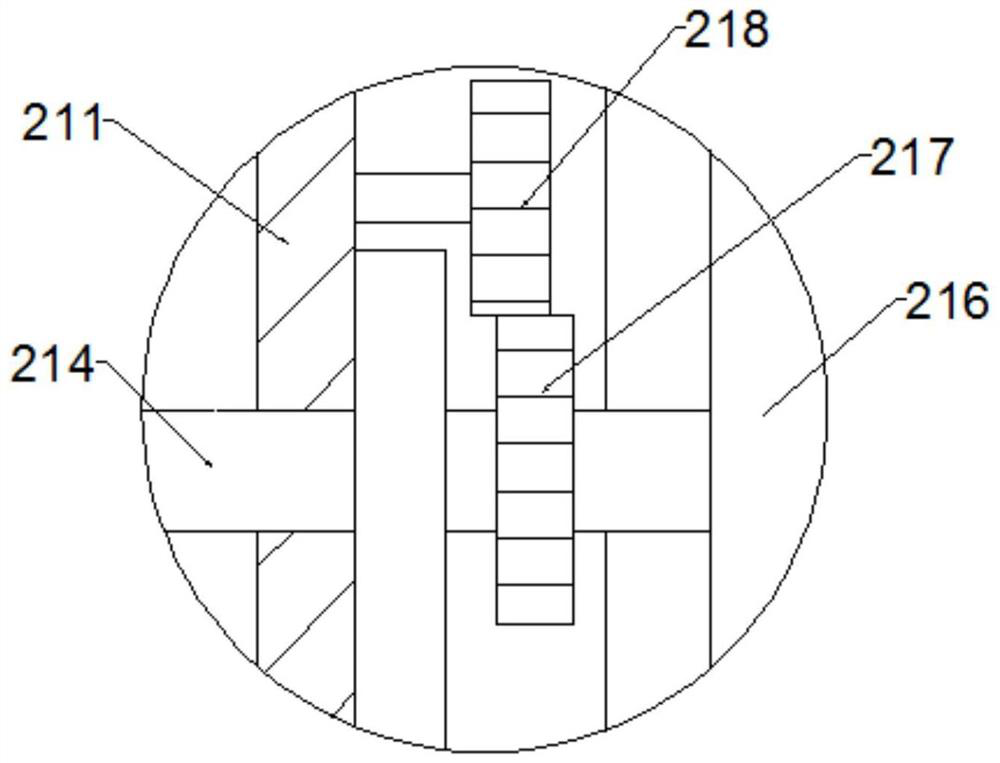

[0047] Pulverizing assembly 2, described pulverizing assembly 2 is arranged on the side close to feed pipe 1 in described main body 1, and described pulverizing assembly 2 comprises pulverizing cylinder 211, fixed seat 216 and motor 212, and the periphery of described pulverizing cylinder 211 The side is provided with a filter screen one and a feed pipe two, the fixed seat 216 is located on both sides of the crushing cylinder 211, the motor 212 is fixed on the fixed seat 216 on one side, and the output of the motor 212 The end is connected with the crushing cylinder 211;

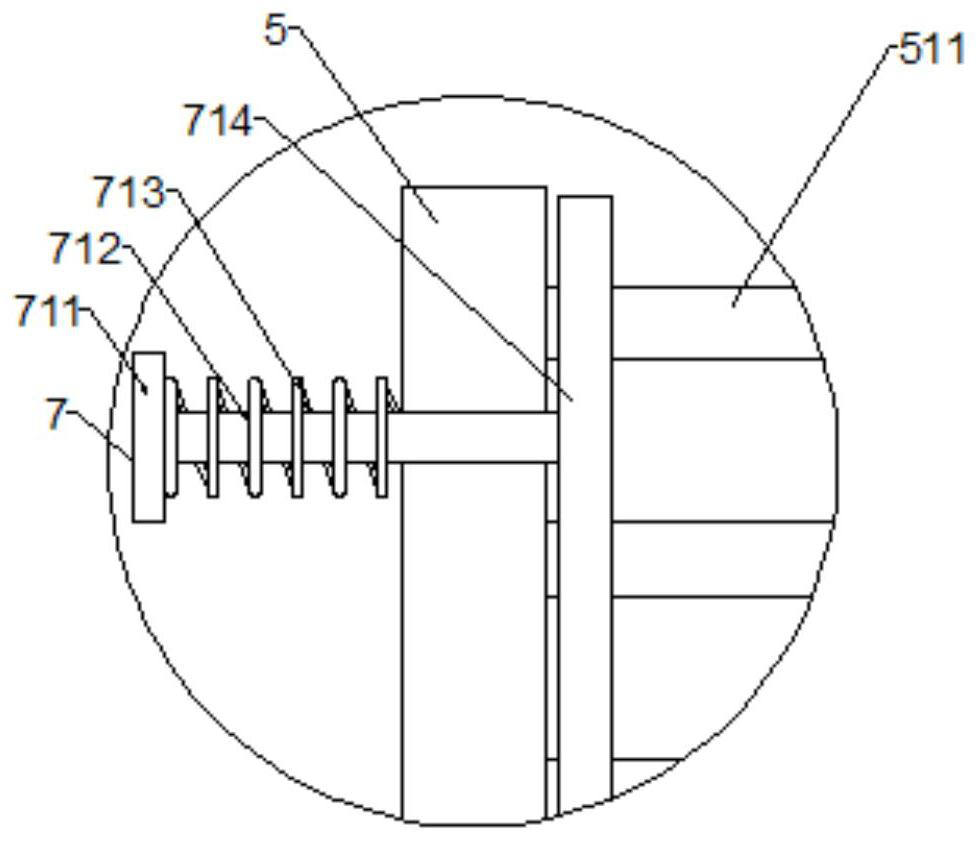

[0048] A guide assembly 3, the guide assembly 3 is arranged on the peripheral side of the crushing assembly 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com