Reaction device and method for capturing carbon dioxide and preparing formic acid through hydrogenation and application

A carbon dioxide and reaction device technology, applied in the field of carbon dioxide capture and hydrogenation formic acid reaction device, can solve the problems of unfavorable large-scale amplification, easy loss of catalyst, poor reaction continuity, etc., to maximize gas-liquid-solid mass transfer efficiency, reduce Amplification effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

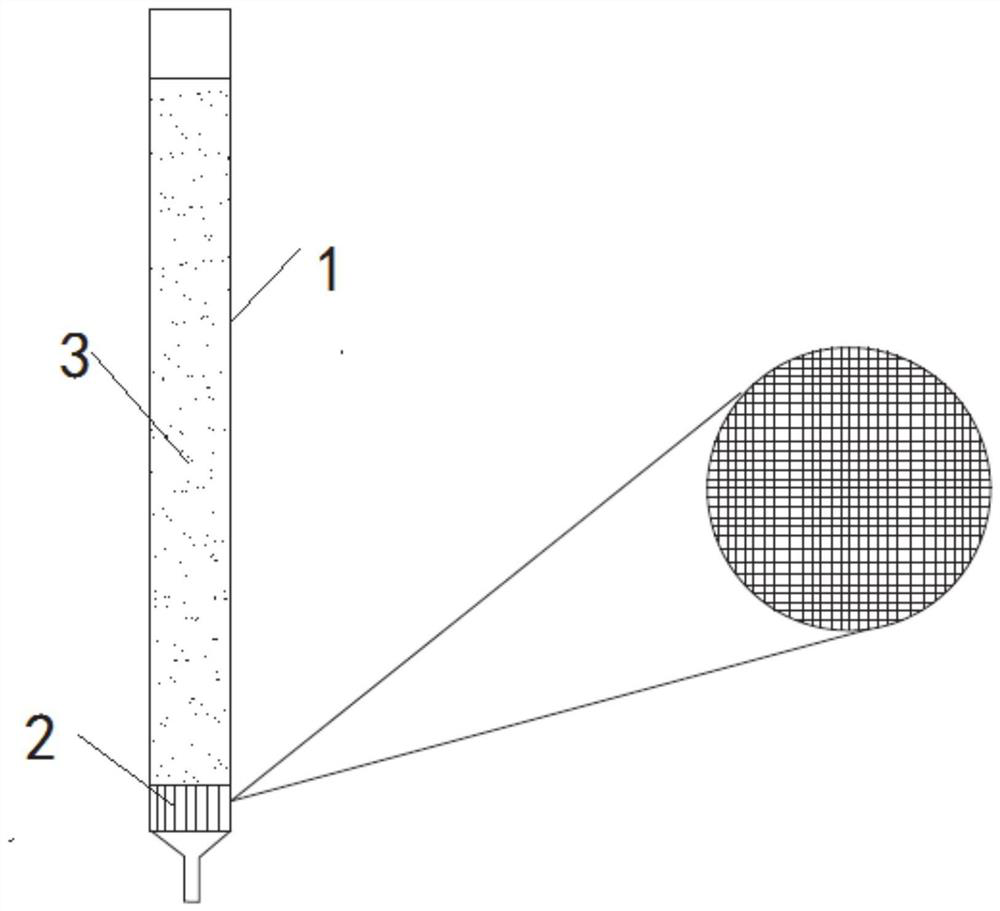

[0052] Examples 1-6 use the carbon dioxide capture and hydrogenation formic acid reaction device provided by the present invention to carry out carbon dioxide capture and hydrogenation reactions in a discontinuous manner, and investigate the capture and hydrogenation performance of different types of organic amine solutions for carbon dioxide. The reactor Such as figure 1 shown. The specific parameters of the reactor are: the diameter of the reaction tube is 1 cm, the length is 20 cm, the aperture of the gas distributor is 15 μm, and the material is glass. The specific operation process is as follows: Weigh a certain mass of catalyst, place it in a reaction tube, then add 5 mL of an aqueous solution of organic amine with a concentration of 2 mol / L, the reaction temperature is room temperature, and the reaction pressure is 1 atmosphere, and then through the bottom of the reactor. Air was introduced to capture carbon dioxide, and after adsorption was saturated, pure hydrogen wa...

Embodiment 7-8

[0056] Examples 7-8 use the carbon dioxide capture and hydrogenation formic acid reaction device provided by the present invention to react in a discontinuous manner to investigate the performance of different concentrations of carbon dioxide capture and hydrogenation reactions. The reactor is such as figure 1 shown. The specific parameters of the reactor are: the diameter of the reaction tube is 1 cm, the length is 20 cm, the aperture of the gas distributor is 15 μm, and the material is glass. The specific operation process is as follows: Weigh a certain mass of catalyst, place it in a reaction tube, then add 5 mL of an aqueous solution of organic amine with a concentration of 2 mol / L, the reaction temperature is room temperature, and the reaction pressure is 1 atmosphere, and then through the bottom of the reactor. Add a certain concentration of carbon dioxide gas for carbon dioxide capture, after the adsorption is saturated, pass pure hydrogen gas for hydrogenation reaction...

Embodiment 9

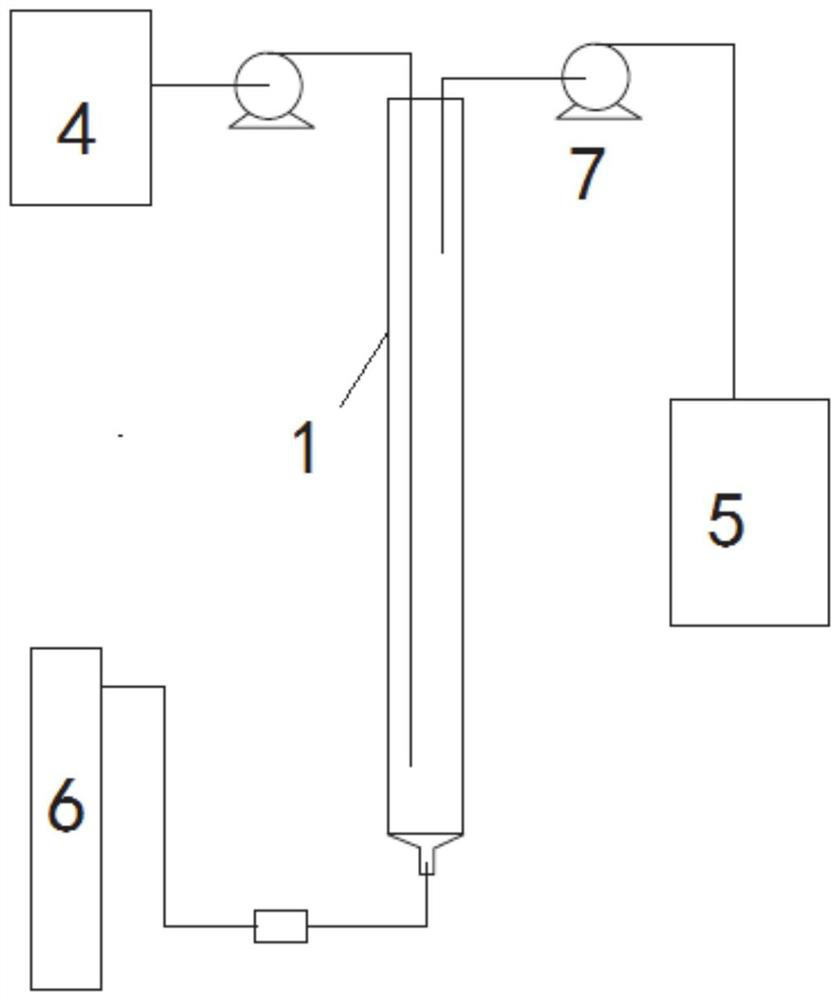

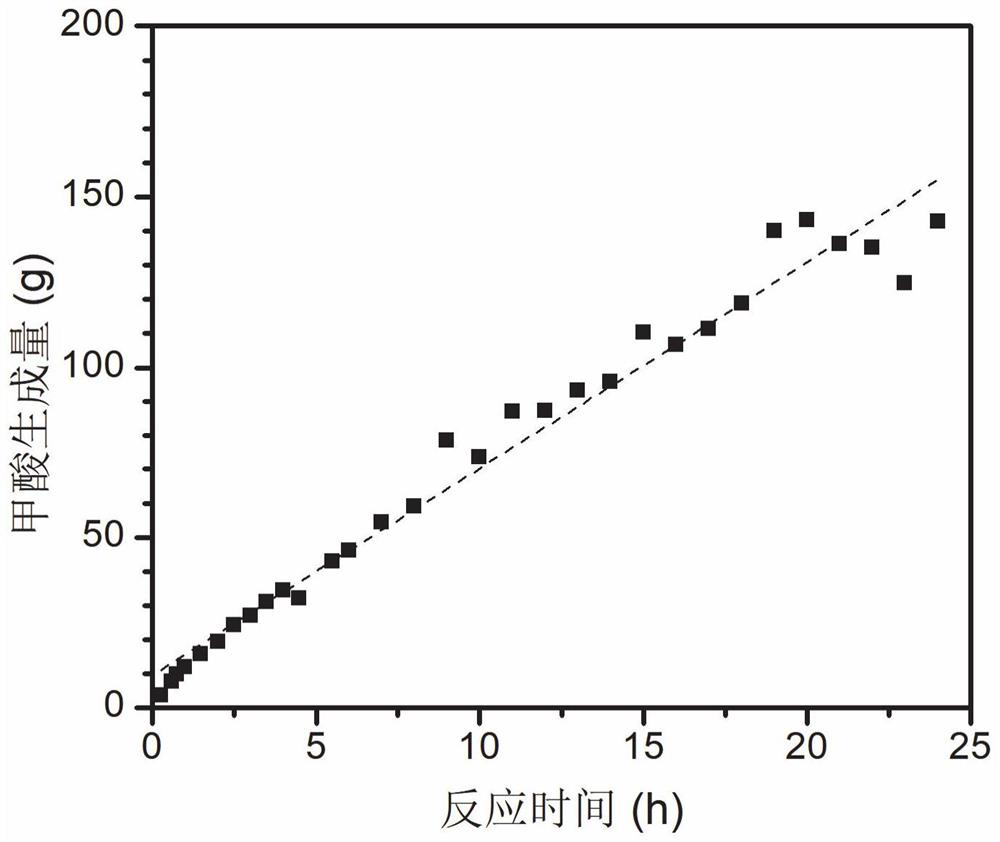

[0060] Example 9 is to use the carbon dioxide capture and hydrogenation reaction device for producing formic acid provided by the present invention, adopting a continuous method of fluidizing the reaction medium to catalyze the direct reaction of carbon dioxide and hydrogen gas mixture to generate formic acid at normal temperature and pressure. The reactor is compared with that of Example 1 -8 Expanded 100 times, carbon dioxide capture and hydrogenation formic acid reaction device such as figure 2 shown. The specific parameters of the reactor are that the diameter of the reaction tube is 5 cm, the length is 1 m, and the aperture of the gas distributor is 30 μm. The reaction medium is circulated by using a peristaltic pump to add a certain amount of fresh alkali solution to the reaction system in real time to the lower end of the reaction tube, and at the same time draw the reacted solution from the top of the reaction tube. Adopt the following operating conditions: normal te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com