Multi-nozzle fire extinguishing device

A fire extinguishing device and multi-nozzle technology, applied in fire rescue and other directions, can solve the problems of intelligent fire extinguishing system efficiency discount, effective control of difficult fires, etc., and achieve the effects of structure and size optimization, good gasification and atomization, and good dispersion of fire extinguishing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

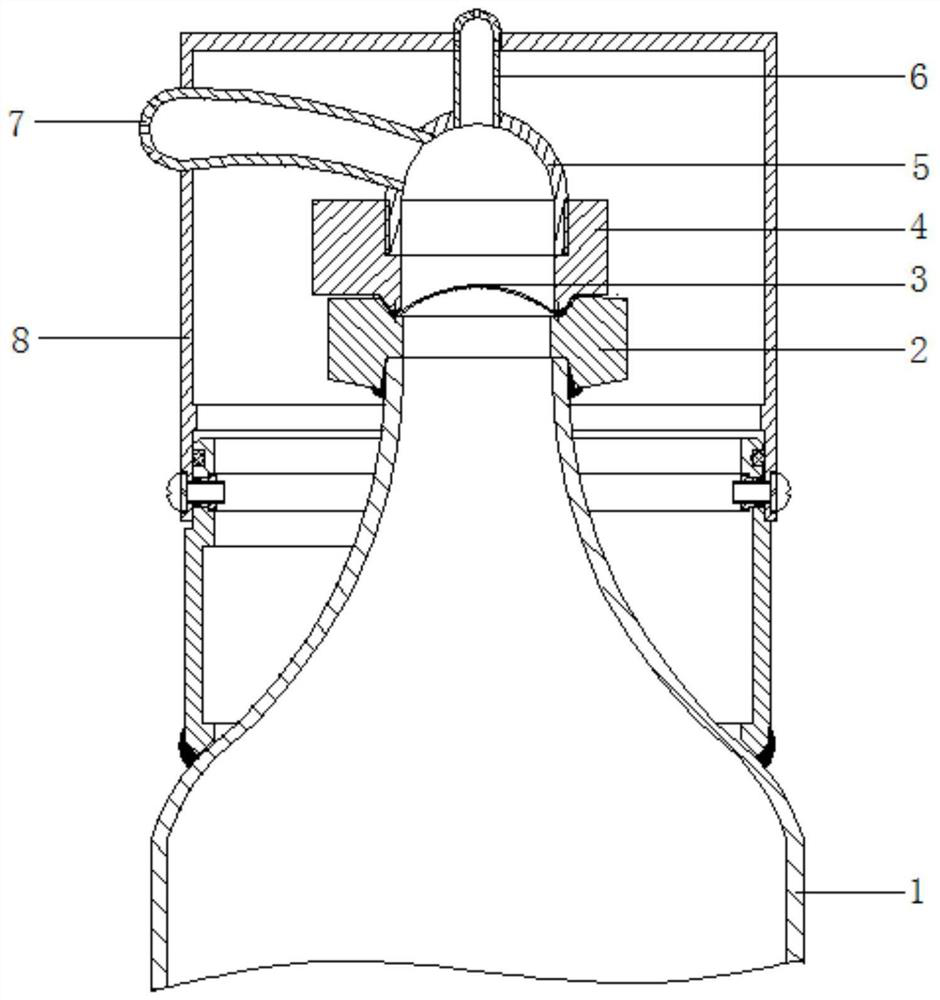

[0018] as attached figure 1 As shown, the present invention provides a multi-spout fire extinguishing device, which includes a bottle body 1 , a shield 8 , a valve seat 2 , a rupture disc 3 , a valve 4 and a nozzle 5 .

[0019] Wherein, the upper part of the nozzle 5 has an upper nozzle 6 and four side nozzles 7, the upper nozzle 6 is located directly above the nozzle, the side nozzles 7 are evenly distributed along the circumference of the nozzle, and the front ends of the upper nozzle 6 and the side nozzles 7 are spherical There are spray holes distributed on the spherical surface; the spray holes on the upper nozzle 6 are composed of a central spray hole and a circle of circumferential spray holes, the axis of the central spray hole coincides with the axis of the upper nozzle 6, and the axis of the circumferential spray hole The included angle with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com