AES disinfection channel spraying method

A channel and disinfection solution technology, which is applied in the direction of disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of insufficient spraying methods, narrow application range, secondary pollution, etc., achieve efficient and stable spraying efficiency, improve disinfection protection, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

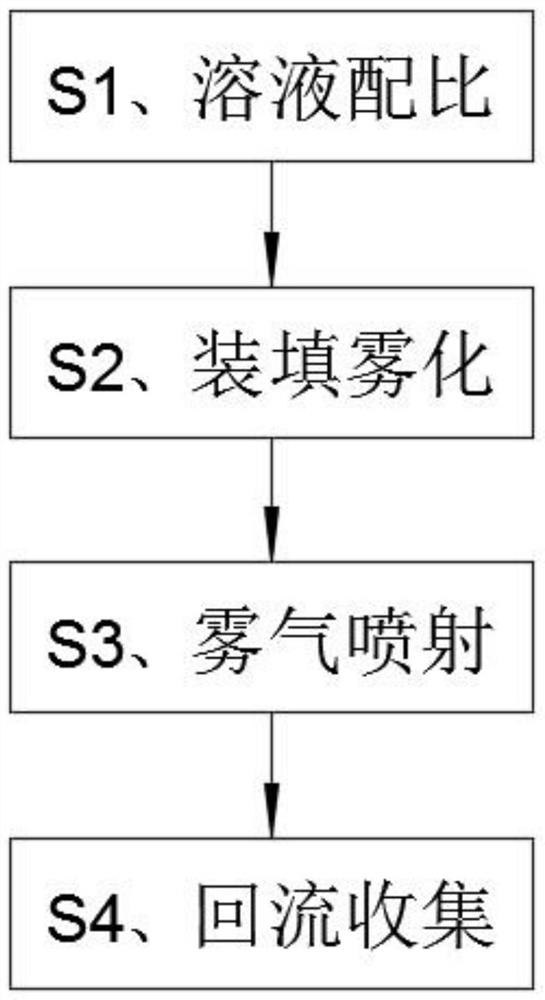

[0038] Such as Figure 1-4 As shown, a AES disinfection channel spray method is characterized in that the following steps are included:

[0039] S1, solution ratio: mix the AES new material with water for 1: 99, then stirred 30s, and the disinfectant solution is obtained;

[0040] S2, filling fitting: Add the sterilization solution to the reservoir 4 of the water tank 4 inside the dust collecting passage by the inlet hole 404, and the liquid level height is located on the lower side of the lateral separator 18, and the water pump 11 and the water pipe 12 will be stored The solution in the liquid zone is pumped into the atomization zone, and the atomizer 20 is discharged from the fog tube 15 after atomizing the solution in the pressure of the fan 16.

[0041] S3, fog injection: fog sequentially passes through the left guiding box body 5, connect the tube 602, the horizontal pipe 603, and the right guiding box body, forms both sides of the spray in the channel by the spray groove 201...

Embodiment 2

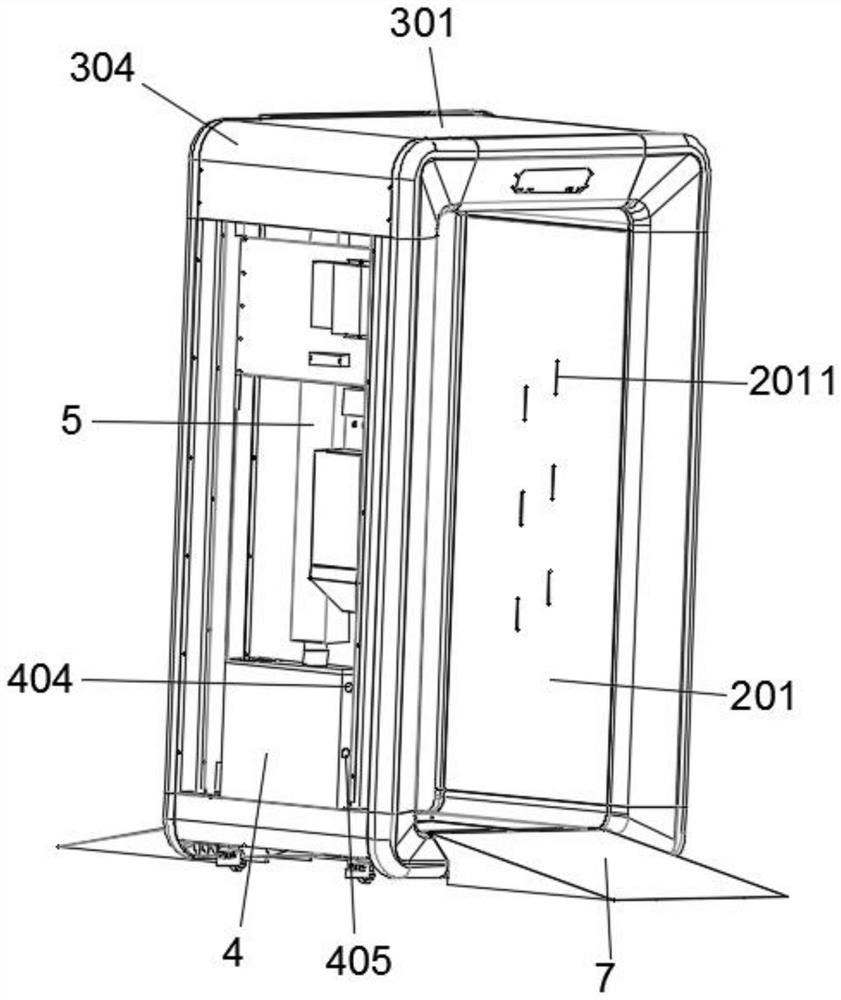

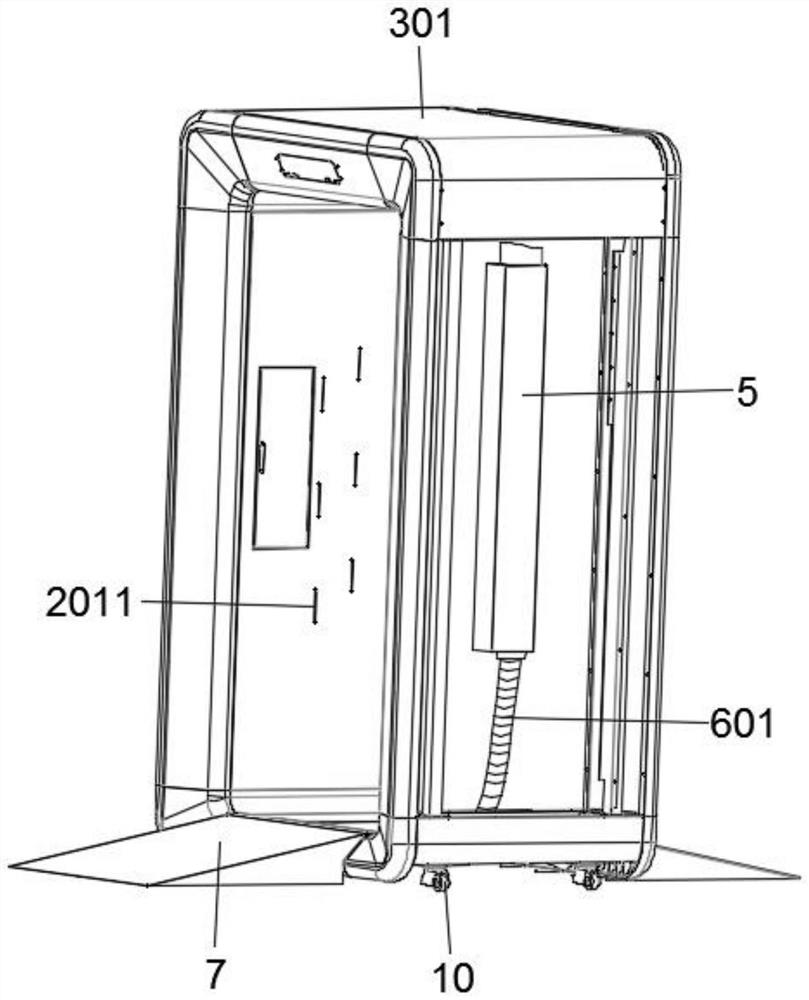

[0046] On the basis of Example 1, ifFigure 1-7 The integrated channel described in step S2, includes a frame 1, the frame 1 including block 101 and a vertical rod 102, the square frame 101 is provided with two groups and up and down, two sets of square block 101 There is a fixed connection between the rod 102;

[0047] The inner plate 2 includes an inner plate 201, an inner top plate 202, an inner bottom plate 203, and an inner arc plate 204, and the upper side of the side frame 101 is fixedly mounted with inner bottom plate 203, and the inner bottom plate 203 Since the internal arc plate 204 is fixed, the upper side of the square frame 101 is fixedly mounted, and the inner arc plate 204 is fixed, and the inner arc plate 204 is fixed, and the inner side plate 201 respectively corresponds to an arc plate, respectively. 204 fixed connection;

[0048] The outer plate 3 includes a top plate 301, an outer plate 302, an outer substrate plate 303, and an outer arc plate 304, and the lowe...

Embodiment 3

[0061] On the basis of the above embodiments, such as Figure 8-11 Indicated;

[0062] The tank 4 is fixed to the top of which is attached to the top of the water tank 4, from left to right, the air outlet 402, the air outlet 402, and the mounting port 403, the water tank 4, front and rear side wall, two side walls, fixed mounting There is a guide plate 17, the guiding plate 17 is inclined toward the air outlet 401 side, and the upper side is fixed to the upper side of the connecting plate 14, and the sealing plate 14 is located on the upper side of the inlet 401. Fan 16 is attached to the opening, the sealing plate 14 is located on the upper side of the air opening 402, and the fog tube 15 is inserted inside the water tank 4;

[0063] The inner left side wall of the water tank 4 is fixedly mounted having a lateral partition 18 and a longitudinal separator 19, and the lateral partition 18 and the longitudinal separator 19 divided the water tank 4 into an atomizing region and a rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com