Dual-channel cooling device for semiconductor laser

A cooling device and laser technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of overheating damage of semiconductor lasers, insufficient heat dissipation efficiency of heat sinks, poor stability and adaptability, etc., to improve heat dissipation and cooling efficiency, accelerate Heat dissipation and cooling efficiency, stable heat dissipation and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

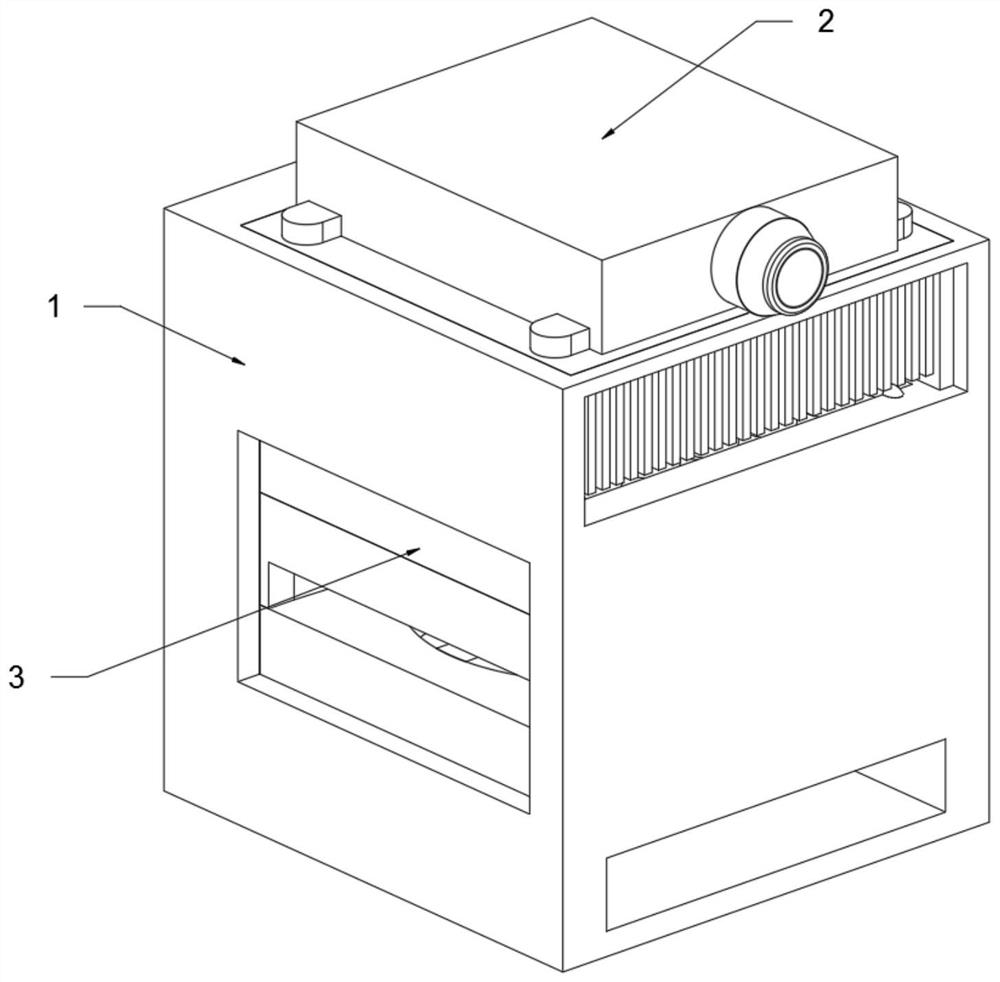

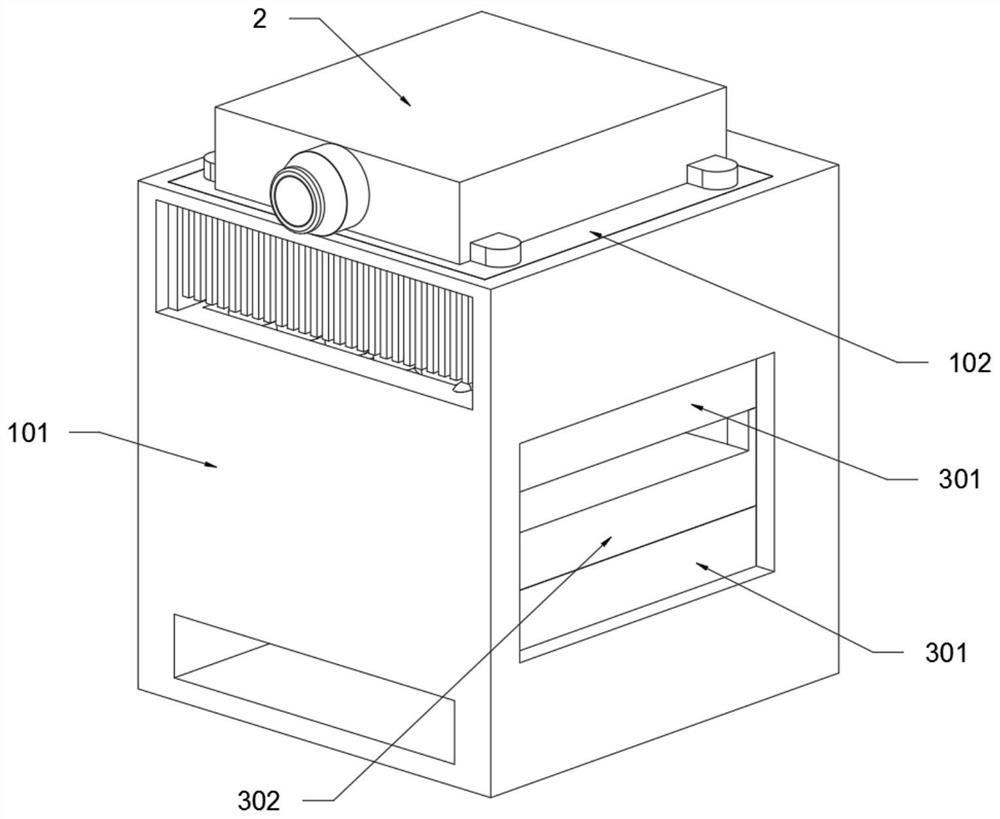

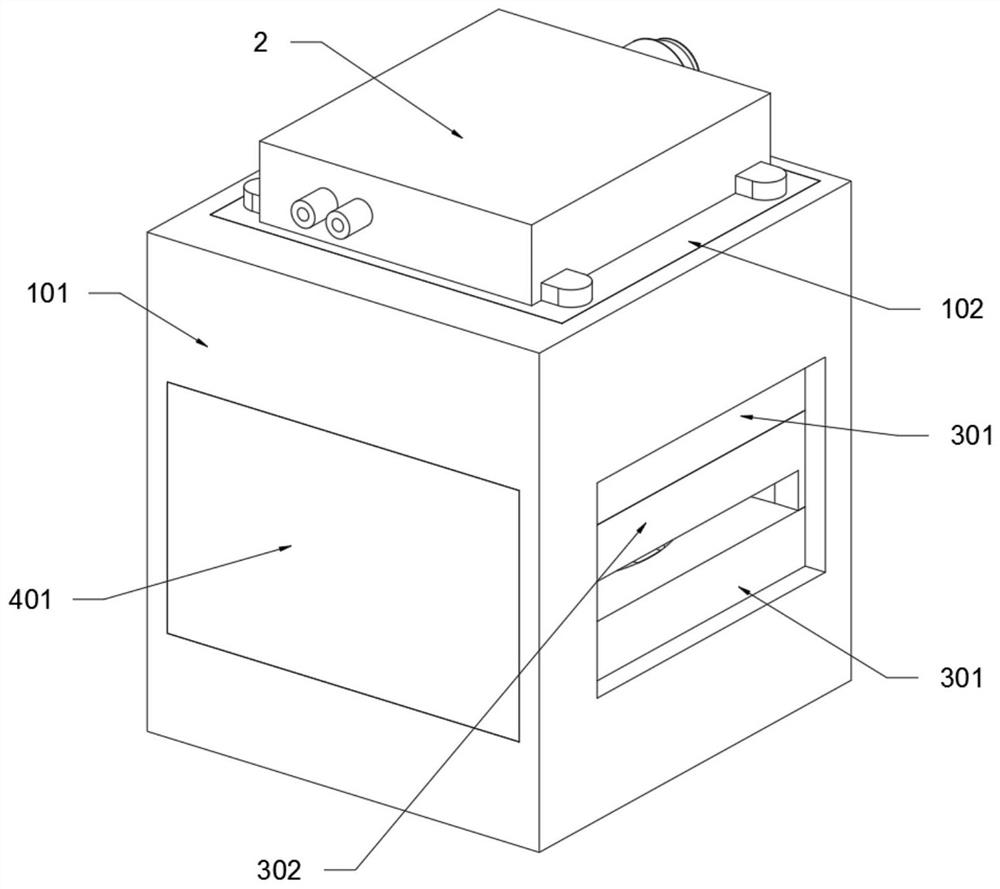

[0036] Example: Please refer to Figure 1 to Figure 8 :

[0037] The present invention proposes a dual-channel cooling device for semiconductor lasers, comprising: a frame assembly 1; the frame assembly 1 includes a mounting frame 101 and a heat sink 102, and the heat sink 102 is fixedly installed on the top of the mounting frame 101; the semiconductor laser 2 , the semiconductor laser 2 is fixedly mounted on the top of the heat sink 102; the heat dissipation cooling assembly, the heat dissipation cooling assembly includes a cooling mechanism 3 and a circulation mechanism 4, the cooling mechanism 3 includes a heat dissipation fan 301 and a deflector 302, and the heat dissipation fan 301 is fixedly installed on The inside of the installation frame 101, and the deflector 302 is fixedly installed inside the installation frame 101; the circulation mechanism 4 includes a circulation cooling box 401, and the circulation cooling box 401 is fixedly installed on the side of the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com