PFC coil device and use method

A technology of coil device and wire plate, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/reactor installation/support/suspension, high-efficiency power electronic conversion, etc., which can solve the problem that the manual winding force is difficult to control and consumes a lot of money Problems such as labor and time, automatic winding of magnetic cores, etc., achieve the effect of facilitating automatic winding, saving costs, and avoiding coil scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

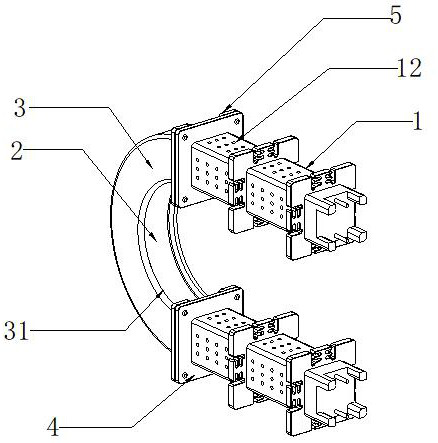

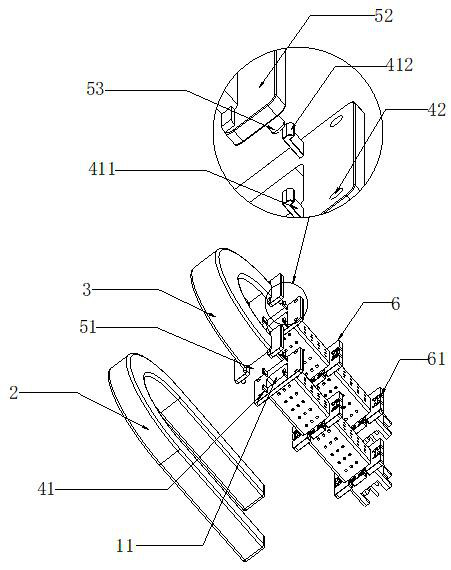

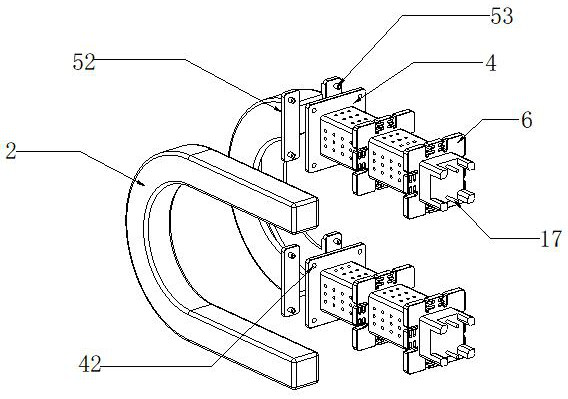

[0047] A PFC coil device, see Figure 1-Figure 6The present invention mainly includes a cuboid winding skeleton 1, a U-shaped magnetic core 2 and an arc-shaped casing 3. In this embodiment, the U-shaped magnetic core 2 is a high-permeability core with small impedance deviation and large output current. High inductance, can suppress high-order harmonics and other characteristics, widely used in electronic equipment such as color TVs, computers, monitors, etc., the number of winding bobbins 1 is two and is wound with wires, and one end of the winding bobbin 1 is provided with a slot 11. The two ends of the U-shaped magnetic core 2 are respectively movably inserted inside the two slots 11. The U-shaped magnetic core 2 matches the size of the slot 11, which can prevent the U-shaped magnetic core 2 from loosening and shaking. Affecting the inductance efficiency, the outer peripheral side of one end of the winding frame 1 is fixedly provided with a mounting plate 4, the cross-sectio...

Embodiment 2

[0057] A PFC coil device, see Figure 1-Figure 9 In the present embodiment, mainly comprise the winding frame 1 of cuboid, I property magnetic core 7, the quantity of winding frame 1 is one and is wound with coil 13, and one end of winding frame 1 offers slot 11, 1 One end of the magnetic core 7 is movably inserted inside the slot 11, and the I magnetic core 7 is adapted to the size of the slot 11, which can prevent the I magnetic core 7 from loosening, shaking, and affecting the inductance efficiency. 1. The fixed sleeve on the outer peripheral side of one end is provided with a mounting plate 4. The cross-sectional area of the mounting plate 4 is larger than the cross-sectional area of the winding skeleton 1. A block 41 is installed on the mounting plate 4. The movable cover is on the opening side of the mounting plate 4. A cover plate 43 is provided, and the block 41 includes an elastic plate 411 vertically fixed on the mounting plate 4. The elastic plate 411 is an elas...

Embodiment 3

[0063] A method for using a PFC coil device, comprising:

[0064] The rectangular parallelepiped winding frame 1 and the arc-shaped casing 3 are formed by injection molding. It should be noted that the mounting plate 4, two wire plates 6, the fixing block 15, the fixing feet 16 and the winding frame 1 are integrally injected, and the clamping plate 5 It is integrally injected with the arc-shaped casing 3, and injection molding is a method for producing and modeling industrial products;

[0065] The wire end 14 on the coil 13 is guided and positioned through the wire groove 61 on the wire plate 6 and the coil 13 is wound on the winding frame 1. According to the application scene of the device, coils 13 with different numbers of turns are selected;

[0066] Select a U-shaped magnetic core 2 with a suitable magnetic permeability, insert the two ends of the U-shaped magnetic core 2 into the slots 11 of the two winding bobbins 1, and set the socket 31 of the arc-shaped casing 3 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com