Optical fiber composite high-voltage power cable

A high-voltage power and optical fiber composite technology, used in power cables, power cables including optical transmission components, insulated cables, etc., can solve the problems of different bending resistance, difficult fault diagnosis by maintenance personnel, and easy breaking of optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

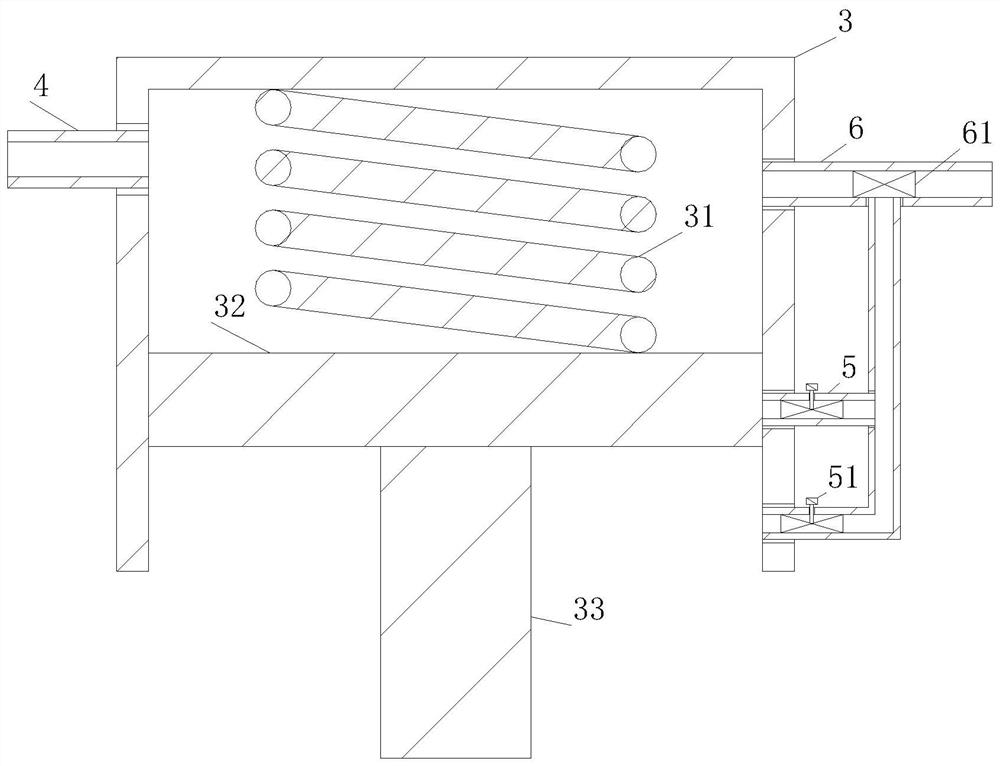

[0032] As an embodiment of the present invention, the inner wall of the airtight box 3 is fixedly installed with a spring 31, and the push plate 32 is connected with the inner wall of the airtight box 3 through the spring 31; the outer side of the airtight box 3 is fixedly installed with Exhaust pipe 6, the interior of the exhaust pipe 6 is fixedly equipped with a pneumatic reversing valve 61; the valves of the outlet pipe 5 and the pneumatic reversing valve 61 are connected to each other; when working, when the composite cable 1 is damaged, the airtight box The gas inside 3 will be discharged through the air outlet pipe 5, and the siren connected to the air outlet pipe 5 will emit a warning sound. It is connected with the valve of the pneumatic reversing valve 61, and the gas discharged from the outlet pipe 5 will enter the valve of the pneumatic reversing valve 61, so that the pneumatic reversing valve 61 conducts, and the exhaust pipe 6 will discharge the gas inside the airt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com