Bending device for seat framework

A bending device and seat frame technology, applied in the field of cushion processing, can solve the problems of no equipment processing, difficult automatic equipment processing, affecting the aesthetics and comfort of the seat, and achieve the effect of convenient support and fixing, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

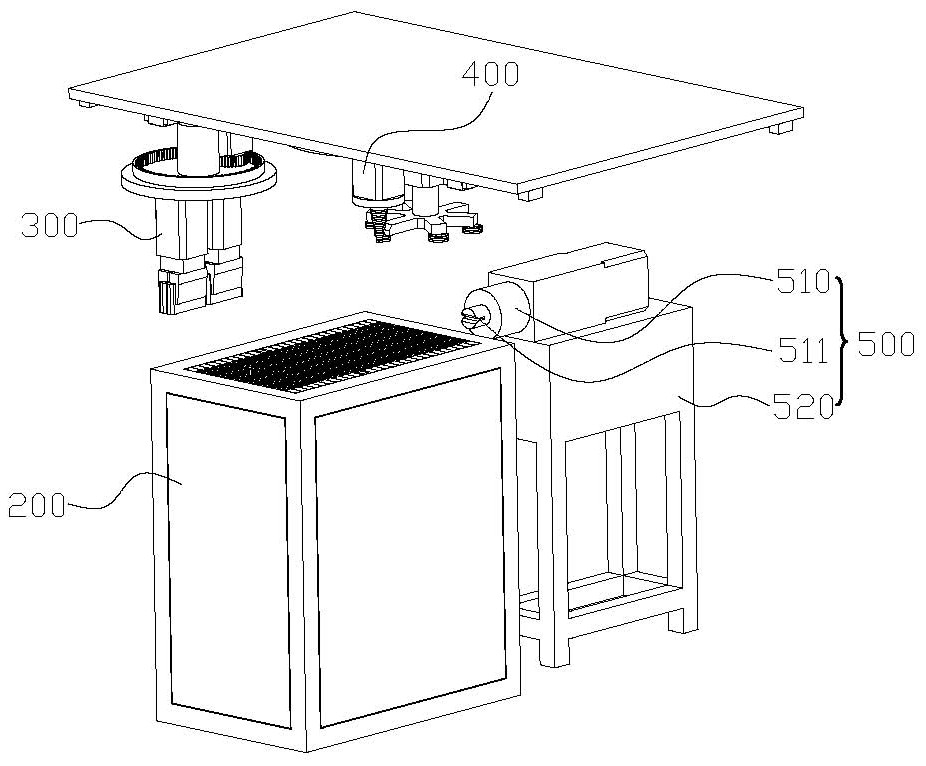

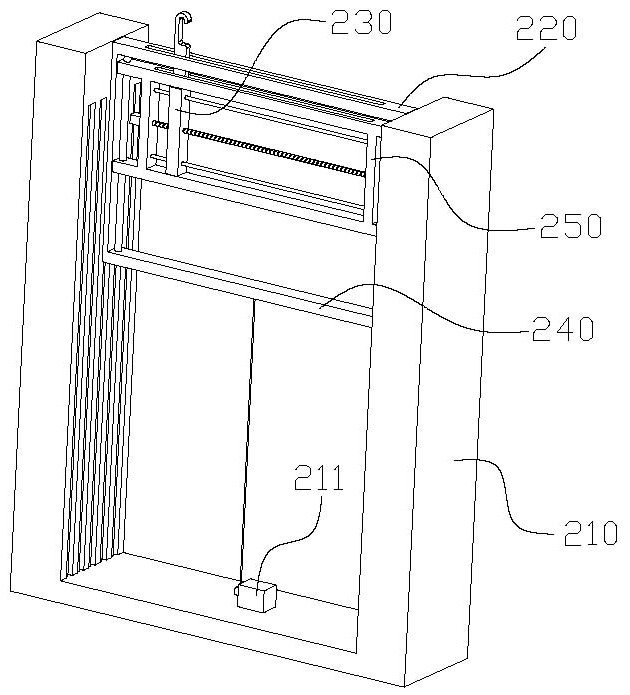

[0028] Combine below Figure 2 to Figure 20 , the present invention is described in further detail.

[0029] In this case, more power units or drive units are involved to drive other parts to move, and the specific structure is not given in detail, because common drive units such as slide rails, screw nuts, and cylinders can be used. The content of the invention is more concise, and only the function of each power unit or drive unit is described below.

[0030] At the same time, in the following content, the advantages of the structures in some solutions have been mentioned above, so in the subsequent description of the solution, only the solution itself will be described, and the advantages or beneficial effects of the solution will not be repeated.

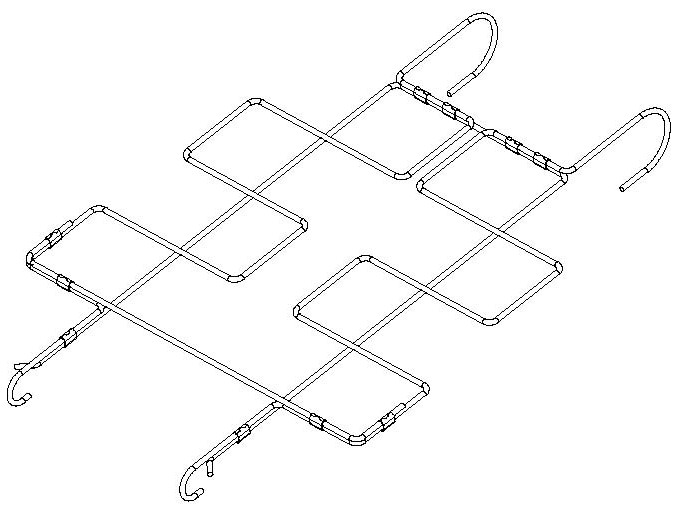

[0031] refer to Figure 2-Figure 8 , the present invention discloses a bending device for a seat frame, comprising a supporting unit 200, a bending unit 400 and a bending unit 300, the supporting unit 200 is used to support th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com