Multi-angle bending machine for electrical cabinet manufacturing

A multi-angle, bending machine technology is applied in the field of electrical cabinet production, which can solve the problems of low production efficiency, poor bending effect, and inability to adjust the bending angle of electrical cabinet profiles according to needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

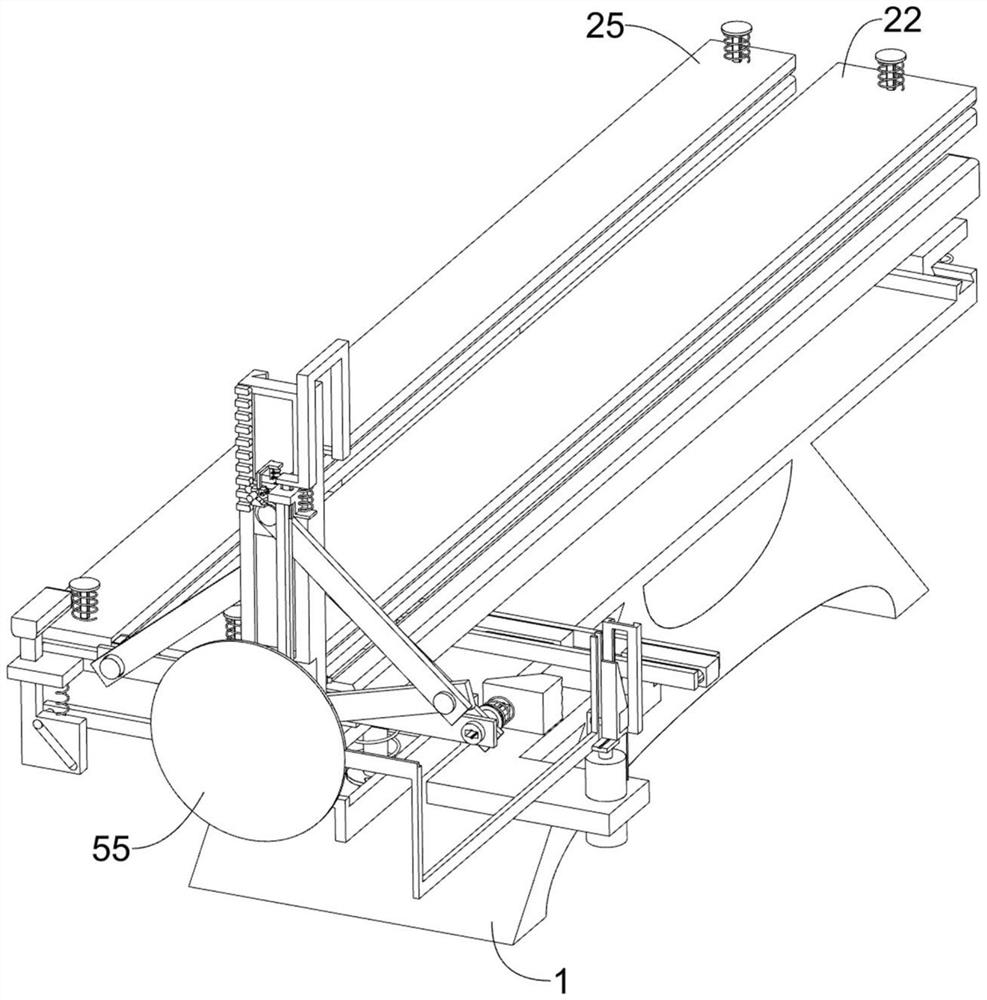

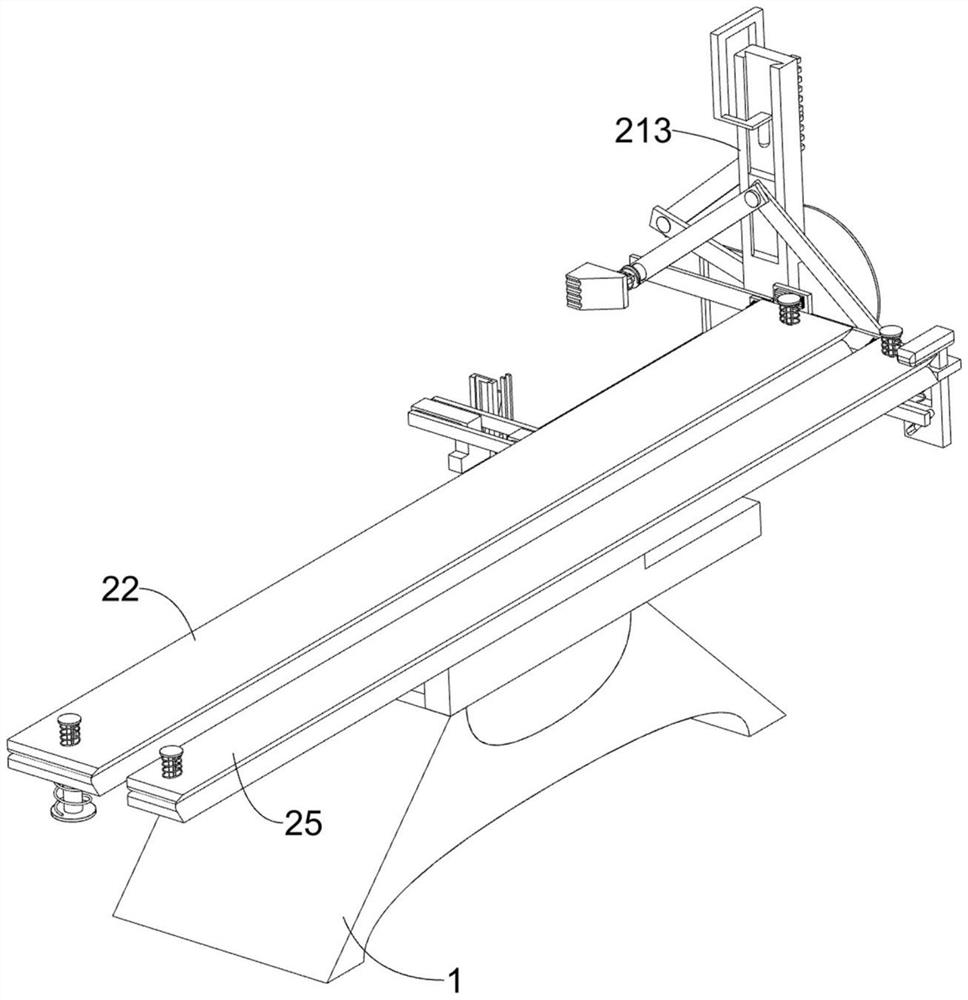

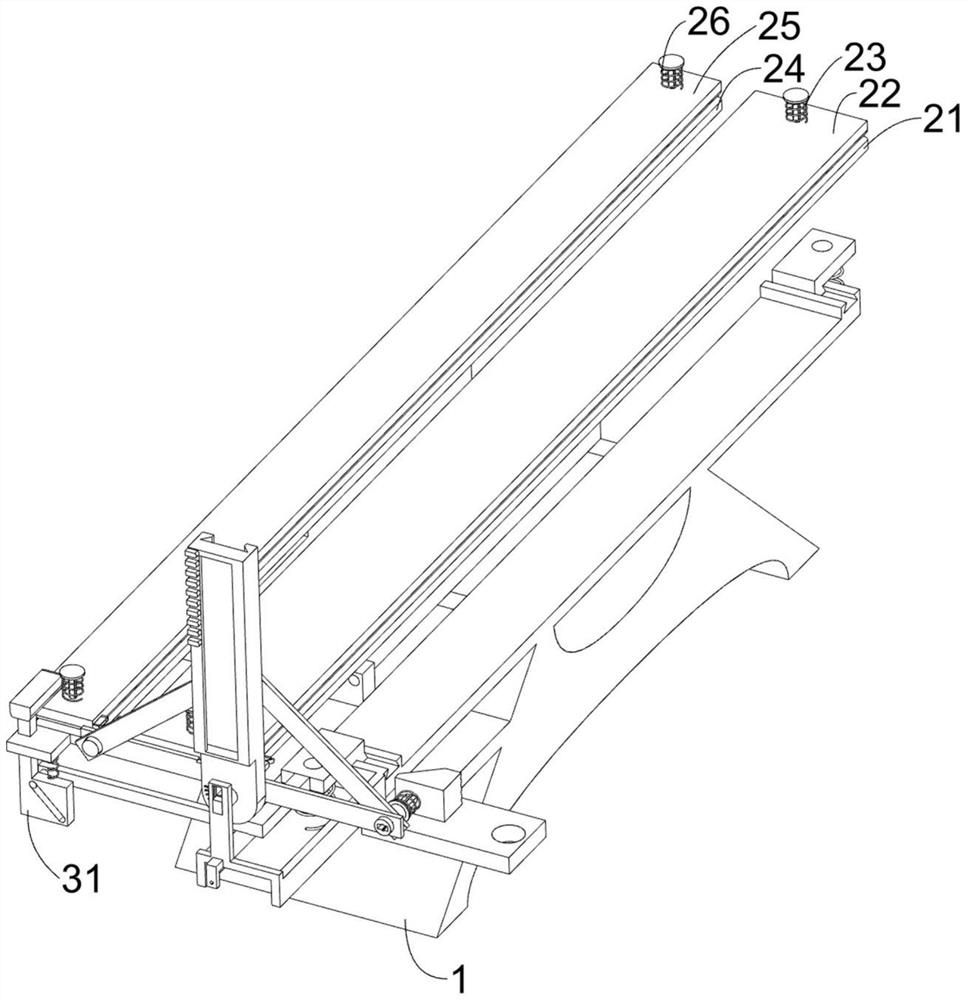

[0030] A multi-angle bending machine for making electrical cabinets, such as Figure 1-12 As shown, it includes a support chassis 1, a limit assembly 2, a bending adjustment assembly 3, a push assembly 4, a termination assembly 5, and a limit clamp assembly 6. The limit assembly 2 is arranged on the support chassis 1, and the bending The adjustment assembly 3 is arranged on the limit assembly 2, the bending adjustment assembly 3 is used to make the equipment suitable for electrical cabinet profiles of different thicknesses, the push assembly 4 is arranged on the support chassis 1, and the termination assembly 5 is arranged on the limit assembly 2 Above, the limit clamp assembly 6 is arranged on the limit assembly 2 , and the limit clamp assembly 6 is used to prevent the third limit plate 24 from being displaced from the electrical cabinet profile on the first limit plate 21 .

[0031]The limiting assembly 2 includes a first limiting plate 21, a second limiting plate 22, a firs...

Embodiment 2

[0042] On the basis of Example 1, such as Figure 11-12 As shown, it also includes an adjustment assembly 7, the adjustment assembly 7 is arranged on the limit assembly 2, the adjustment assembly 7 is used to adjust the bending angle of the profile of the electrical cabinet according to the demand, the adjustment assembly 7 includes a third swing plate 71, a fourth Swing plate 72, block 73, adjustment push frame 74, the ninth spring 75, card frame 76 and the tenth spring 77, the third swing plate 71 is connected in rotation on the sliding support frame 27, and the third swing plate 71 is used to indicate The scale value on the swing slide rail frame 212, the third swing plate 71 is connected with the fourth swing plate 72 in rotation, the fourth swing plate 72 is used to drive the third swing plate 71 to swing, the fourth swing plate 72 and the first adjustment The sliding frame 51 is rotatably connected, and the swing rail frame 212 is distributedly connected with blocks 73, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com