Modal test suspension device and modal test system

A modal test and suspension device technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of small application range and complicated operation of air springs, so as to avoid safety accidents and improve convenience Performance and reliability, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

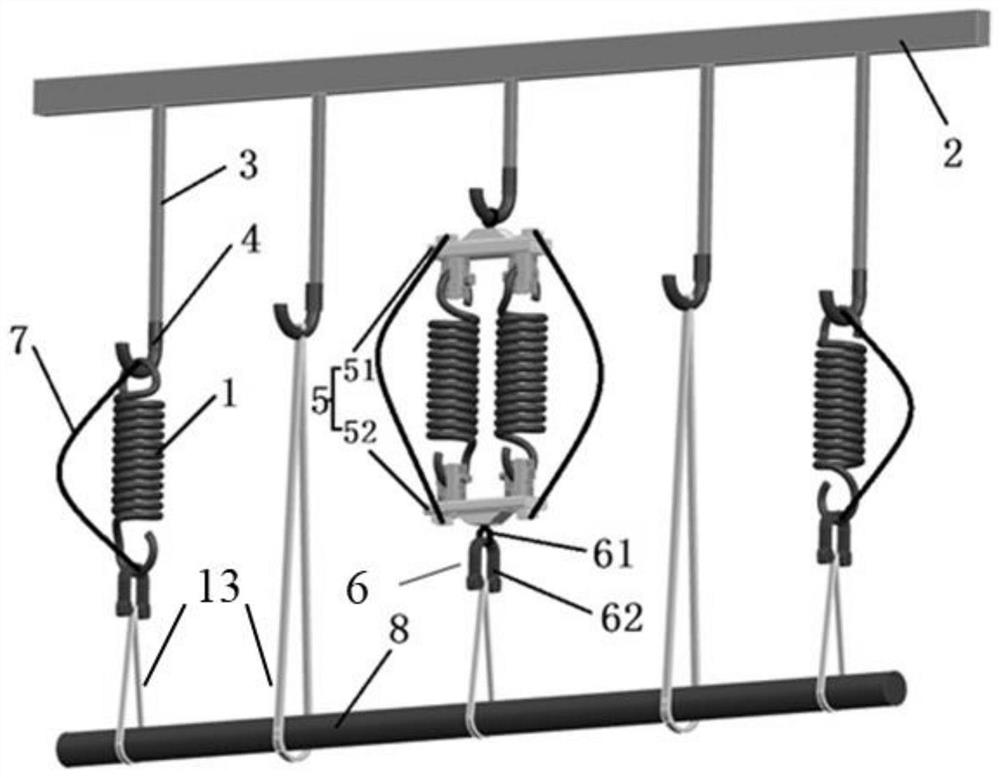

[0052] see figure 1 , a specific embodiment of the present invention discloses a modal test suspension device. The modal test suspension device of this embodiment is used for high-precision parameter measurement of 3-5 Hz aerospace product modal tests with long length (more than 20 meters), larger volume and heavier weight (more than 30 tons).

[0053] The modal test suspension device of this embodiment includes: a suspension assembly and a test piece 8 connected to the suspension assembly; the suspension assembly includes a plurality of steel springs 1, and the technical parameters of the steel springs 1 are based on the test piece 8 weight and fundamental frequency to determine.

[0054] During implementation, the effect of modal test suspension device among the present invention is to make the test piece 8 of modal test be in suspension state, and simulate free-free boundary condition, measure the structural modal parameter of test piece 8 under free-free state .

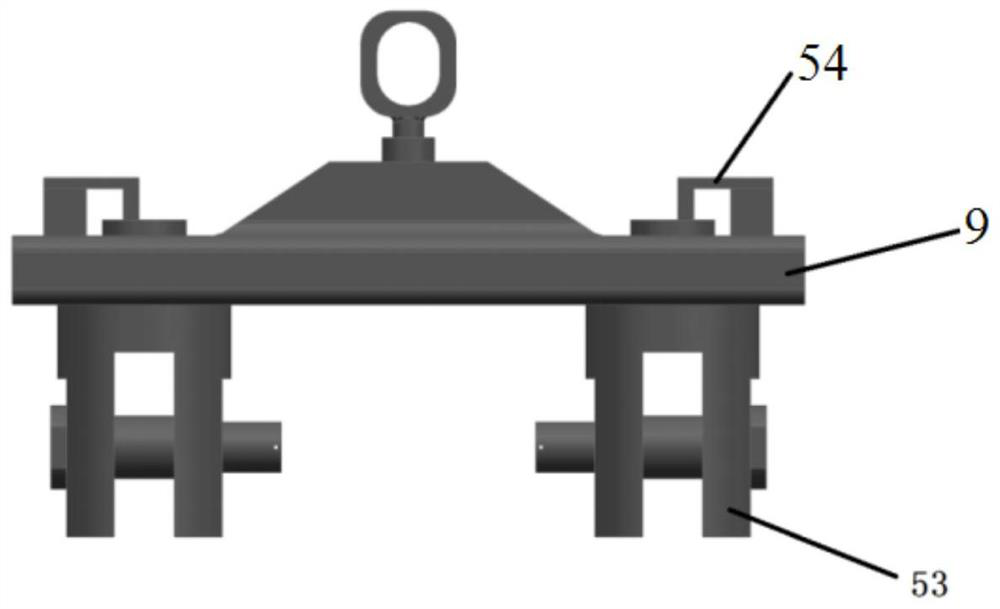

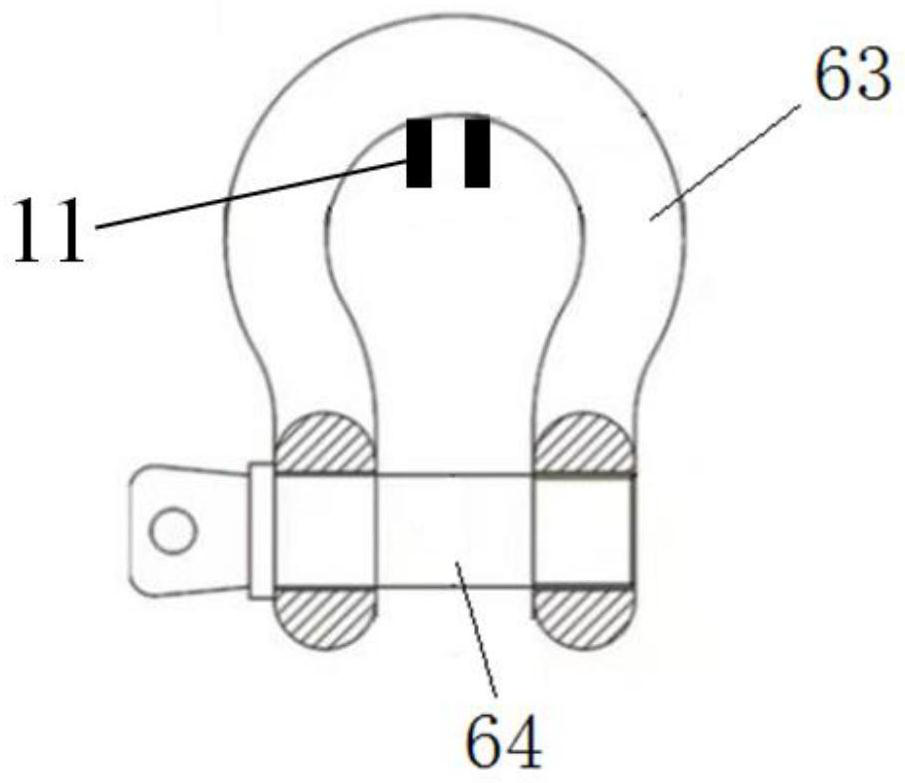

[0055...

Embodiment 2

[0087]Another embodiment of the present invention provides a suspension method for carrying out a modal test using the suspension device of Embodiment 1, which specifically includes the following steps:

[0088] Design the technical parameters of the steel springs included in the suspension assembly, said technical parameters including the wire diameter of the steel spring, the outer diameter of the spring, the direction of rotation, the elongation length and the bearing capacity;

[0089] According to the determined technical parameters, a suspension assembly is used to suspend the test piece so that the test piece is in a free-free boundary condition.

[0090] In the above specific method, the design method of the technical parameters is to determine the technical parameters of the spring according to the axial deformation of the steel spring, wherein the calculation formula of the axial deformation is:

[0091]

[0092] In the above formula:

[0093] λ is the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com