Special negative pressure ventilation system for production improvement of cement kiln

A ventilation system and cement kiln technology, applied in waste heat treatment, dispersed particle filtration, lighting and heating equipment, etc., can solve the problems of heavy burden on the staff, low work efficiency, large air pollution, etc., and achieve simple assembly and convenient loading and unloading Effects of maintenance and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

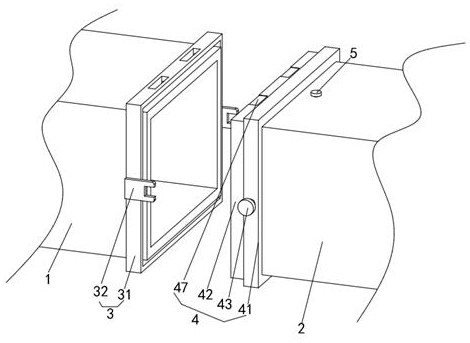

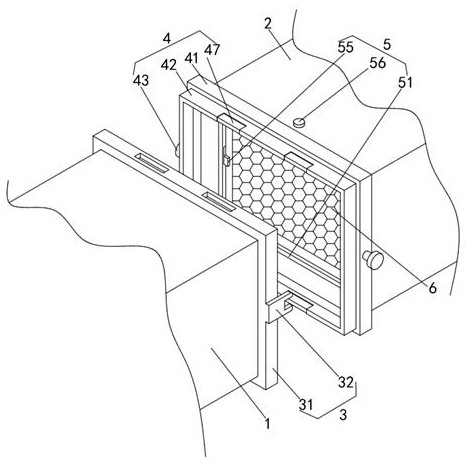

[0023] Such as figure 1 and Figure 3-4 As shown, a special negative pressure ventilation system for cement kilns proposed by the present invention includes air duct one 1, air duct two 2 and filter mechanism 6, and one end of air duct one 1 is provided with a clamping mechanism one 3 One end of the air duct pipe two 2 is provided with a clamping mechanism two 4, and the interior of the air duct two 2 is provided with a clamping mechanism 5, and the clamping mechanism one 3 includes a fixed frame one 31 arranged on the air duct one 1 , the front and back shell walls of the fixed frame one 31 are provided with backing plates 32;

[0024] The clamping mechanism 2 4 includes a fixed frame 41 arranged on the air duct pipe 2 2, the left side of the fixed frame 41 is fixedly connected with an insert frame 42, and the front and back shell walls of the fixed frame 41 are movably connected with Screw mandrel one 43, the inner end of screw mandrel one 43 is rotatably connected with co...

Embodiment 2

[0027] Such as Figure 2-3 As shown, a special negative pressure ventilation system for cement kiln production proposed by the present invention, compared with Embodiment 1, this embodiment also includes: a slot is opened on the fixed frame 1 31, and the top and bottom of the slot are all set There are a plurality of connection holes positioned on the fixed frame one 31, the inside of the fixed frame two 41 is provided with a cavity one, the front and back shell walls of the fixed frame two 41 are all provided with threaded holes, and the outer end of the screw rod one 43 is threaded. Through the threaded hole, and a handle is installed, grooves are provided on the top and bottom shell walls of the socket frame 42, and a cavity 2 is provided on the inner side of the groove, and the transmission shaft is rotatably connected to the cavity 2.

[0028] In this embodiment, the clamping block 47 is located in the groove, so that the clamping block 47 is inserted into the slot along ...

Embodiment 3

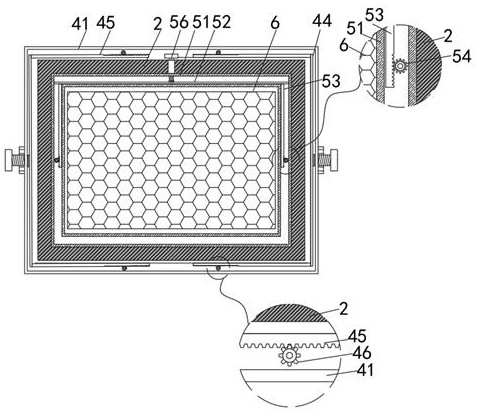

[0030] Such as image 3 and Figure 5 As shown, a special negative pressure ventilation system for cement kilns proposed by the present invention, compared with Embodiment 1 or Embodiment 2, this embodiment also includes: the clamping mechanism 5 includes a frame body 51, a slide plate 52, teeth Bar two 53, gear two 54, backing plate 55 and screw mandrel two 56, the inside of frame body 51 is provided with movable cavity, the inside of movable cavity is slidingly connected with slide plate 52, and the top of slide plate 52 is connected with screw rod two 56, and the top of slide plate 52 is connected with screw rod two 56. The top of rod two 56 passes through the top shell wall of frame body 51 and air duct pipe two 2, and both sides of the bottom of slide plate 52 are provided with rack two 53, and the side of rack two 53 is provided with gear two 54, and gear two A connecting shaft is installed on the 54, and one end of the connecting shaft far away from the second gear 54 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com