Electrolytic stripping solution composition of copper-plated hanger and stripping solution cyclic regeneration method

A stripping solution and composition technology, which is applied in the field of electrolytic stripping solution composition and stripping solution cycle regeneration, can solve the problems of complex composition, high content of copper and nickel ions, high acidity, etc., and achieve the effect of overcoming difficult treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

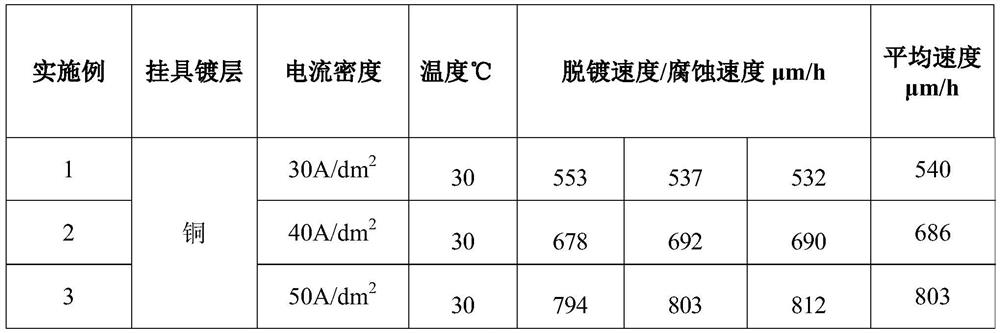

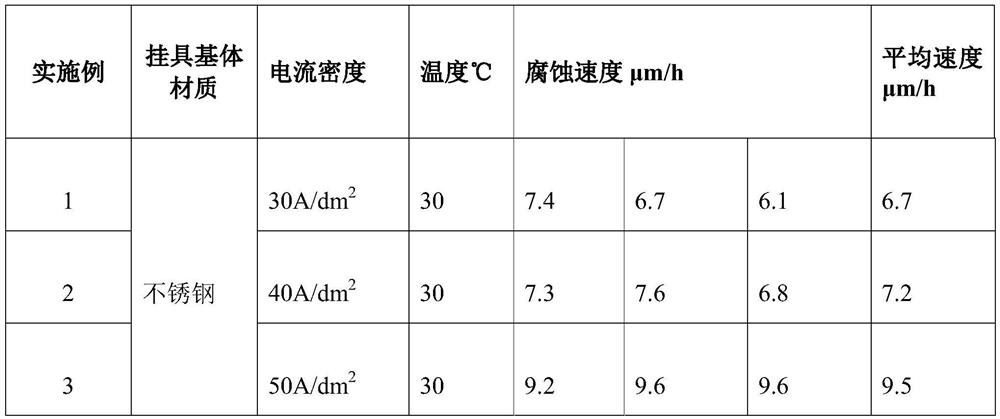

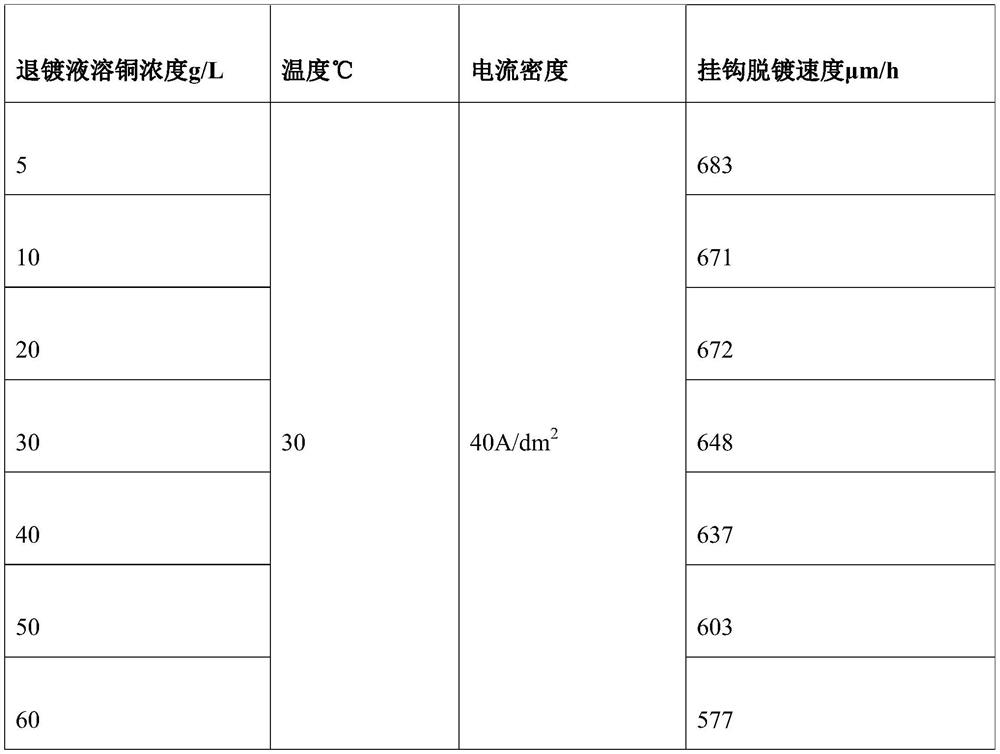

Examples

Embodiment 1

[0032] The electrolytic deplating solution composition of copper-plated hanger comprises the nitrate of 140g / L, the complexing agent of 90g / L, the accelerator of 5g / L, the solid corrosion inhibitor of 2.5g / L and the organic Corrosion inhibitor, the solid corrosion inhibitor is a mixture of thiourea and hexamethylenetetramine, the weight ratio of thiourea and hexamethylenetetramine is 1:0.2, and the electrolytic annealing of the copper-plated rack The plating solution composition is adjusted to a pH of 6.5-7.5 with a pH regulator.

[0033] In some embodiments of the present invention, the nitrate in the formulation system of the electrolytic deplating solution composition of the above-mentioned copper plating rack is sodium nitrate.

[0034] In some embodiments of the present invention, the complexing agent in the formulation system of the electrolytic deplating solution composition of the above-mentioned copper plating rack is EDTA.

[0035] In some embodiments of the present...

Embodiment 2

[0041] The composition of the electrolytic deplating solution for copper-plated racks includes 120g / L of nitrate, 60g / L of complexing agent, 0.5g / L of accelerator, 7g / L of solid corrosion inhibitor and 0.5-3g / L of Organic corrosion inhibitor, the solid corrosion inhibitor is a mixture of thiourea and hexamethylenetetramine, the weight ratio of thiourea and hexamethylenetetramine is 1:2.1, the electrolysis of the copper-plated rack The stripping solution composition is adjusted to pH 6.5-7.5 with a pH regulator.

[0042] In some embodiments of the present invention, the nitrate in the formulation system of the electrolytic deplating solution composition of the above-mentioned copper plating rack is sodium nitrate.

[0043] In some embodiments of the present invention, the complexing agent in the formula system of the electrolytic deplating solution composition for the above-mentioned copper plating rack is ethanolamine.

[0044] In some embodiments of the present invention, th...

Embodiment 3

[0050] The composition of the electrolytic deplating solution for copper-plated racks includes 180g / L of nitrate, 120g / L of complexing agent, 10g / L of accelerator, 12g / L of solid corrosion inhibitor and 3g / L of organic corrosion inhibitor agent, the solid corrosion inhibitor is a mixture of thiourea and hexamethylenetetramine, the weight ratio of thiourea and hexamethylenetetramine is 1:4, and the electrolytic deplating solution of the copper plating rack The composition is adjusted to pH 6.5-7.5 with a pH regulator.

[0051] In some embodiments of the present invention, the nitrate in the formulation system of the electrolytic deplating solution composition of the above-mentioned copper plating rack is sodium nitrate.

[0052] In some embodiments of the present invention, the complexing agent in the formula system of the electrolytic stripping solution composition of the above-mentioned copper plating rack is oleic acid.

[0053] In some embodiments of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com