Mildew-proof composite elastomer

An elastomer and anti-mildew technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of sponges that are not resistant to high temperature, high humidity, mildew, anti-bacteria, etc., and achieve tear resistance Strong ability, cushioning and rebound performance, not easy to deform, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

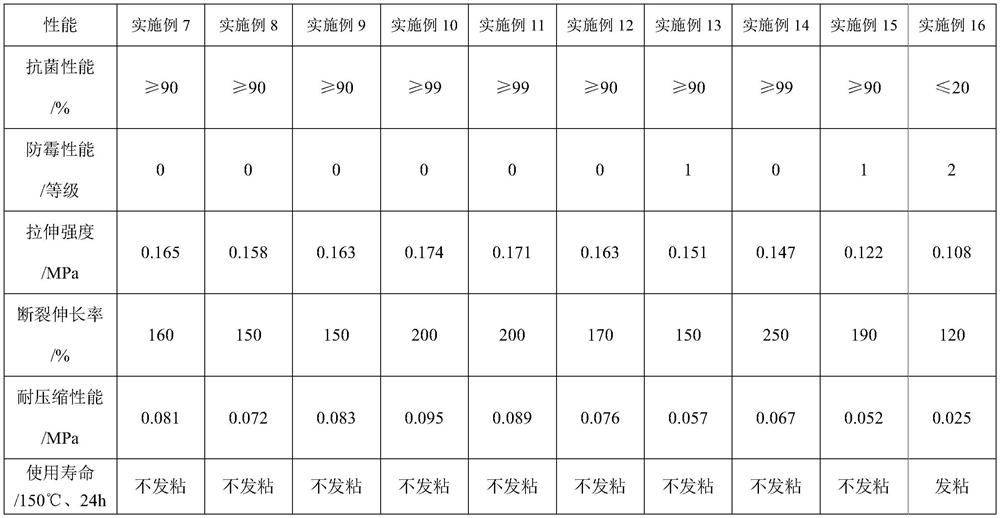

Examples

Embodiment 1

[0029] 1) Preparation of R-Br (R is citronellyl):

[0030] Dissolve 5mL of citronellol and 2mL of phosphorus tribromide in 30mL of anhydrous ether respectively, add aminooligosaccharin solution and 0.45mL of pyridine into a three-necked flask, stir rapidly under ice-salt bath conditions, and then add tribromide Phosphate solution was slowly added dropwise to the above reaction system. After the dropwise addition, continued to stir rapidly for 45 minutes, and then washed with 5% sodium bicarbonate solution, deionized water and saturated saline for 3 times, and dried by adding anhydrous magnesium sulfate. , filtered through a 0.22um membrane filter, and concentrated by rotary evaporation at 35°C for 30min to obtain a light yellow oily liquid citronellyl bromide.

[0031] 2) Preparation of amino oligosaccharin-ROH derivatives (R is citronellyl):

[0032] After dissolving 1g of amino oligosaccharin and 2mL of citronellyl bromide in dimethyl sulfoxide and dimethyl formamide respec...

Embodiment 2

[0034] 1) Preparation of R-Br (R is cinnamyl):

[0035] Similar to Example 1.

[0036] 2) Preparation of amino oligosaccharin-ROH derivatives (R is cinnamyl):

[0037] Similar to Example 1, the yield was 63%.

Embodiment 3

[0039] 1) Preparation of R-Br (R is linalyl):

[0040] Similar to Example 1.

[0041] 2) Preparation of amino oligosaccharin-ROH derivatives (R is linalyl):

[0042] Similar to Example 1, the yield was 69%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap