Equipment for sleeving connecting part with pipe fitting

A technology for connecting parts and pipe fittings, which is applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of easy overturning of connecting parts, carrying out of connecting parts, and low yield rate of connecting parts in the socketing process, and achieves The effect of improving production efficiency and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As a common heat exchange component, heat pipe heat exchangers are widely used in scenarios such as water heaters and automobile cooling systems. The heat pipe heat exchanger contains multiple heat pipes. In the manufacturing process, the heat pipes need to be bent into a preset shape by using pipe bending equipment. The existing pipe bending equipment generally includes a pipe inlet device, a pipe cutting device, a front pipe end device, and a rear pipe end device. The pipe end device and the pipe bending device are equipped with a conveying device between the front pipe end device and the rear pipe end device. It is equipped with an automatic socketing device for connecting parts. Through the above design, the pipe bending equipment can integrate multiple functions and effectively realize a high degree of automatic production, thereby effectively improving production efficiency.

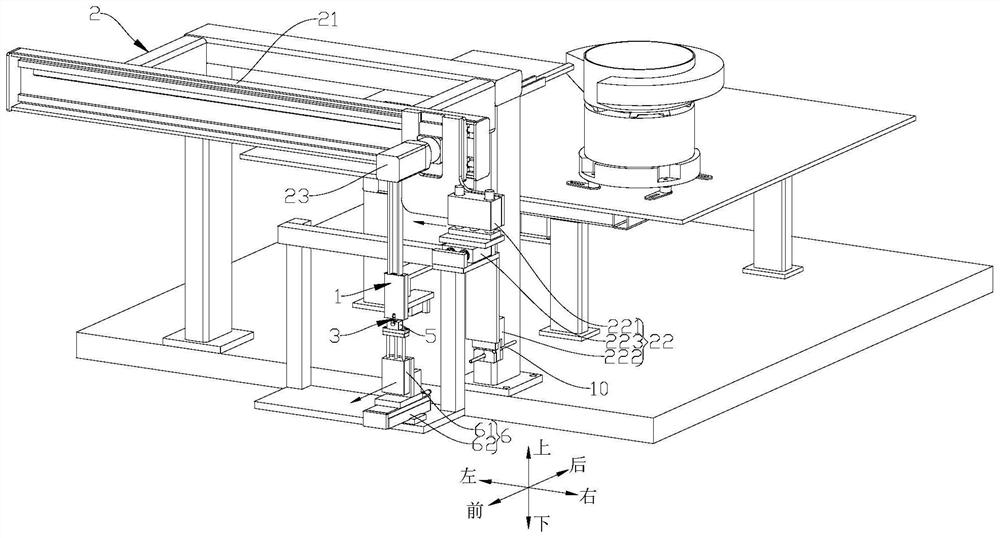

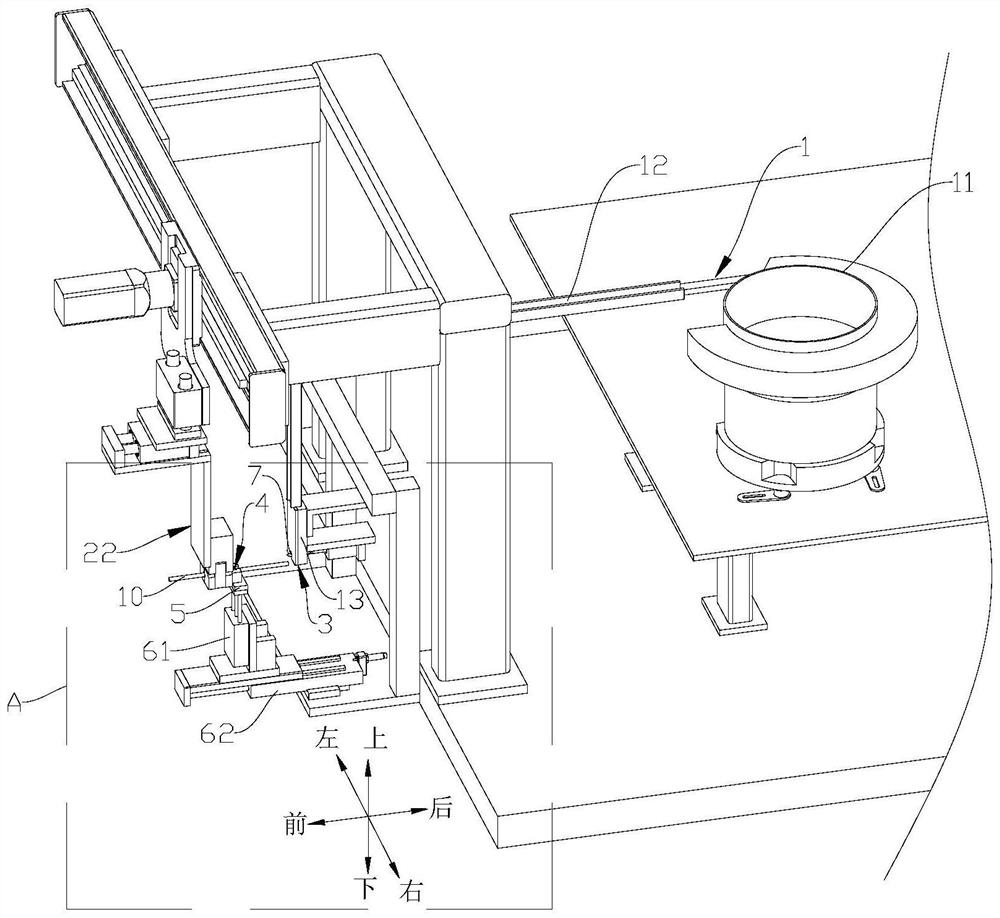

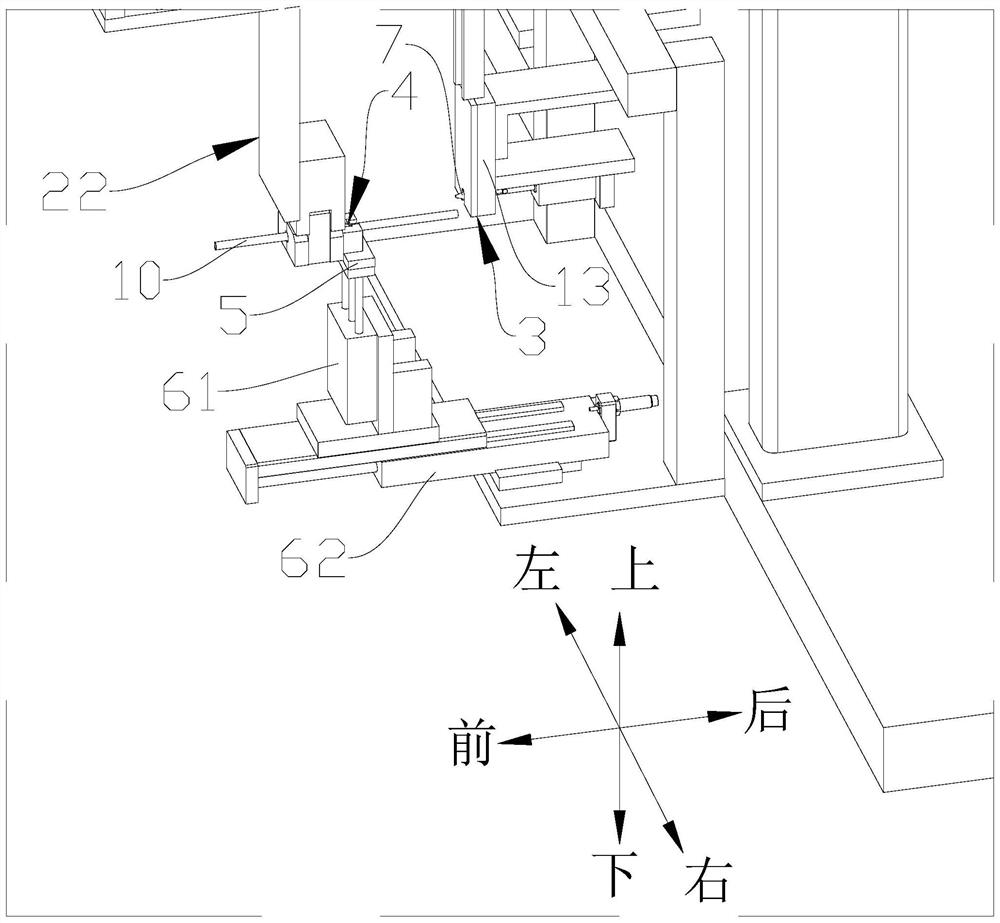

[0030] Such as Figure 1 to Figure 5 As shown, this embodiment provides a kind of equip...

Embodiment 2

[0042] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a processing method for socket connection parts of pipe fittings 10, and provides the equipment for socket connection parts of pipe fittings 10 described in Embodiment 1, including the following steps:

[0043] Driving the pipe transfer device 2 to transfer the pipe 10 from the previous station to the nesting station 4 corresponding to one of the feeding devices 1;

[0044] Drive the first linear driver 61 to move, and transport the receiving seat 52 to the loading station 3;

[0045] Drive the limit assembly 7 to move, so that the bottom connecting part in the material storage assembly 13 falls to the material receiving seat 5, and when the connecting part falls to the material receiving seat 5, the limit assembly 7 is driven to reset to limit the material storage assembly 13 activities of the connecting parts on the outlet;

[0046] Drive the second linear driver 62 to act, transport the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com