Ductile iron pouring system with filtering and positioning device and use method of ductile iron pouring system

A pouring system and positioning device technology, which is applied in the direction of manufacturing tools, casting molding equipment, mechanical cleaning, etc., can solve problems such as difficult to achieve gapless bonding, high labor intensity for slag removal, and waste of raw materials, so as to avoid low prices The effects of selling out, saving electricity time, and improving styling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

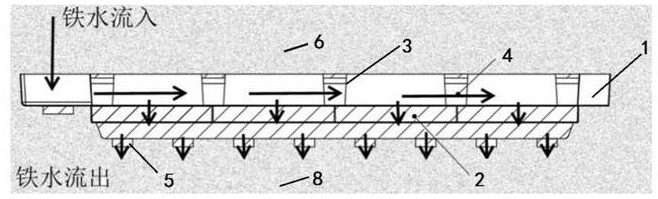

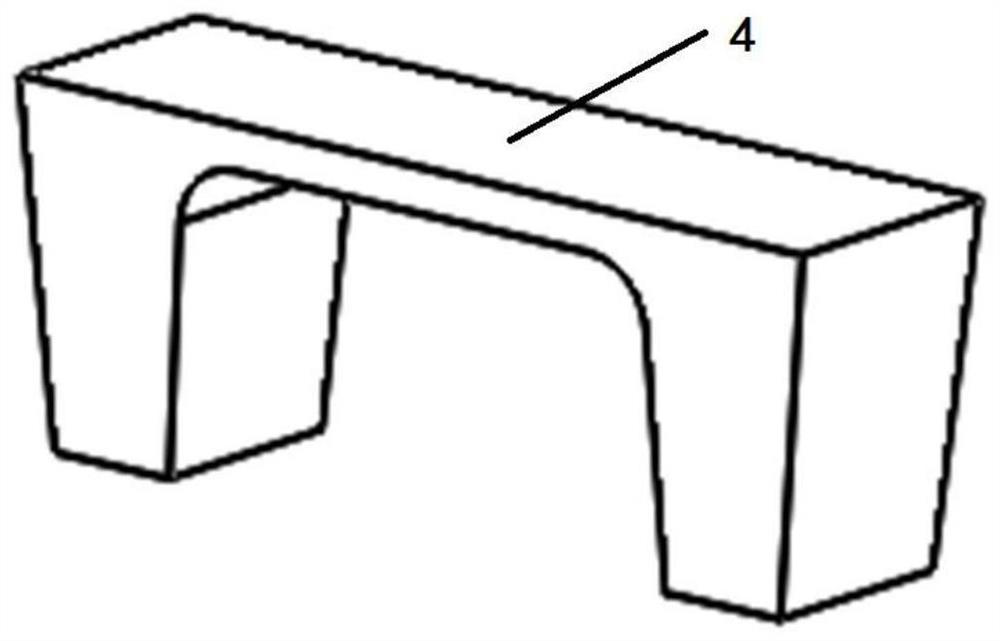

[0043] Such as Figure 1~4 As shown, a ductile iron gating system with a filter positioning device includes a gating system 1, the gating system is in the shape of a stepped groove, and is divided into an upper groove and a lower groove; there are multiple gating systems along the lower groove The filter screen 2 closely arranged in the length direction of 1, the groove wall of the upper groove has a protruding positioning notch 3 between two adjacent filter nets 2, and there is an upper The filter screen positioning device 4 in the groove; the filter screen positioning device 4 adopts a gantry structure, and the arrangement direction of the two legs at the bottom is parallel to the width direction of the pouring system 1, and the outer side of each leg is in line with the upper groove. The groove bottom is contacted and connected, and the inner side of the leg is located above the filter screen 2, and there is a gap of 1-2mm between the filter screen 2, so as to prevent the f...

Embodiment 2

[0045] Such as Figure 1~4 As shown, a method for using a ductile iron pouring system with a filter positioning device, including:

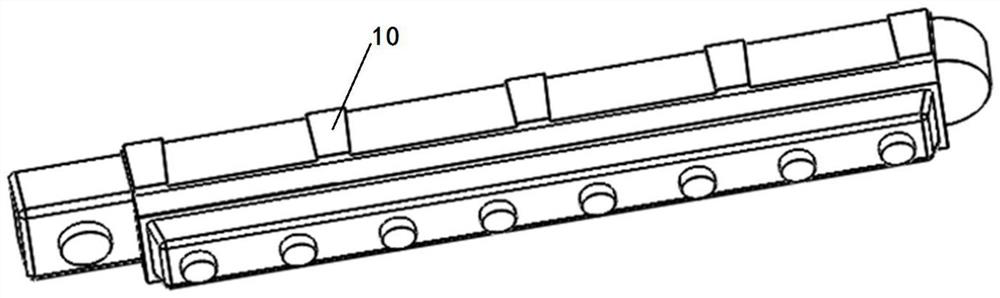

[0046] (1) Prepare the gating system model 7, set the protrusion 10 according to the placement position of the filter screen 2, and the protrusion 10 forms the positioning notch 3 of the gating system 1; The gating system model 7 is made of wood material.

[0047] (2) prepare the filter screen positioning device 4 that matches with the positioning notch 3; the filter screen positioning device 4 can be a standard part, and it must not have depressions or protrusions or cracks; the design of the positioning notch 3 can reserve 1~ 2mm assembly clearance;

[0048] (3) Place the gating system model 7 according to the requirements of the casting process drawings, and complete the assembly with other components such as the ceramic pouring pipe 5, start the sand filling molding, sink the gating system model 7 into the lower sand mold 8, and use manual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com