Integrated reversible hydrogen fuel cell high-pressure sealing element

A fuel cell and high-pressure sealing technology, which is applied in the field of electrolytic cells, can solve the problems of easy misalignment of sealing rings, sealing contact pressure, large compressive stress, etc., and achieve the effect of improving sealing performance and meeting the needs of high-pressure sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

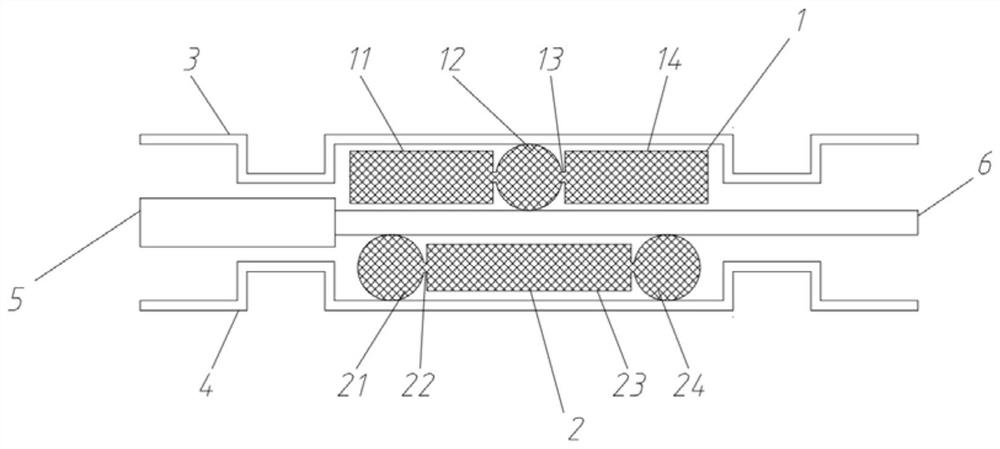

[0036] One-piece reversible high-pressure sealing components for hydrogen fuel cells, including hydrogen-side sealing rings and oxygen-side sealing rings; the hydrogen-side sealing rings adopt an odd-numbered composite sealing structure with rectangular structures and O-shaped structures arranged at intervals, and the oxygen-side sealing rings use O-shaped sealing rings. Odd-numbered composite sealing structure with rectangular structure and rectangular structure arranged at intervals.

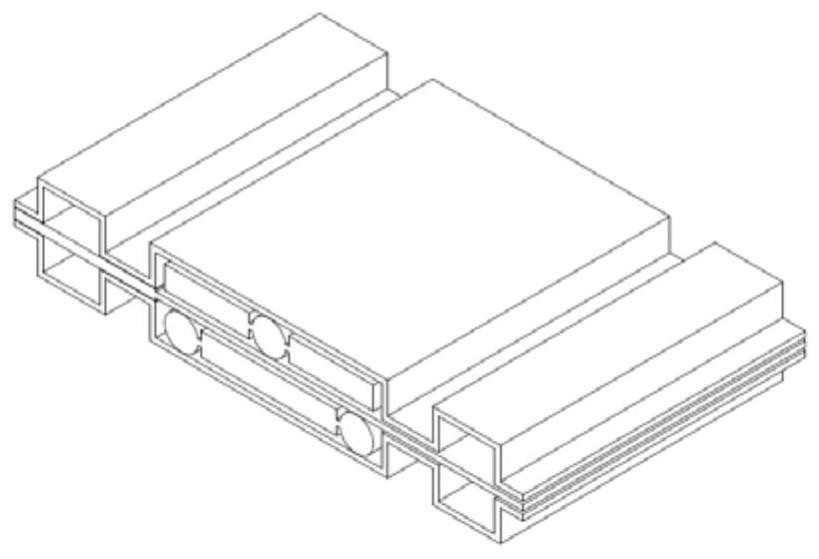

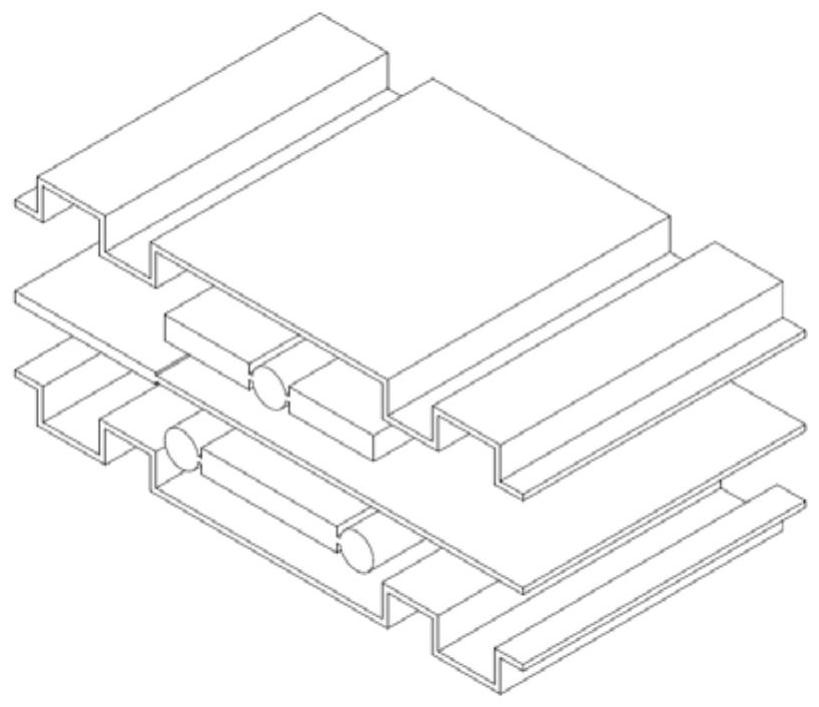

[0037] like Figure 1-6As shown, a complete integrated reversible fuel cell structure includes an oxygen plate 3, a hydrogen plate 4, a membrane electrode 5 and a membrane electrode frame 6, and oxygen is provided between the oxygen plate 3 and the membrane electrode frame 6. A hydrogen side sealing ring 2 is arranged between the side sealing ring 1 , the hydrogen electrode plate 4 and the membrane electrode frame 6 . An oxygen-side sealing ring 1 and a hydrogen-side sealing ring 2 are arrang...

Embodiment 2

[0052] A new type of high-pressure sealing structure for an integrated reversible hydrogen fuel cell, including hydrogen side sealing rings and oxygen side sealing rings; The side sealing ring adopts an O-shaped structure and an odd-numbered composite sealing structure with rectangular protrusions arranged at intervals.

[0053] A complete integrated reversible fuel cell structure includes an oxygen plate 3, a hydrogen plate 4, a membrane electrode 5 and a membrane electrode frame 6, and an oxygen side sealing structure is provided between the oxygen plate 3 and the membrane electrode frame 6 1. A hydrogen-side sealing structure 2 is provided between the hydrogen electrode plate 4 and the membrane electrode frame 6 . An oxygen-side sealing structure 1 and a hydrogen-side sealing structure 2 are provided between the hydrogen electrode plate 4 , the oxygen electrode plate 3 and the membrane electrode frame 6 to ensure good sealing performance of the membrane electrode 5 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com