Method for constructing parameterized model of liquid rocket engine

A technology of engine parameters and liquid rockets, applied in 3D modeling, image data processing, design optimization/simulation, etc., can solve problems such as low efficiency, achieve automatic transmission, improve processing efficiency and quality, and realize real-time driving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

[0037] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

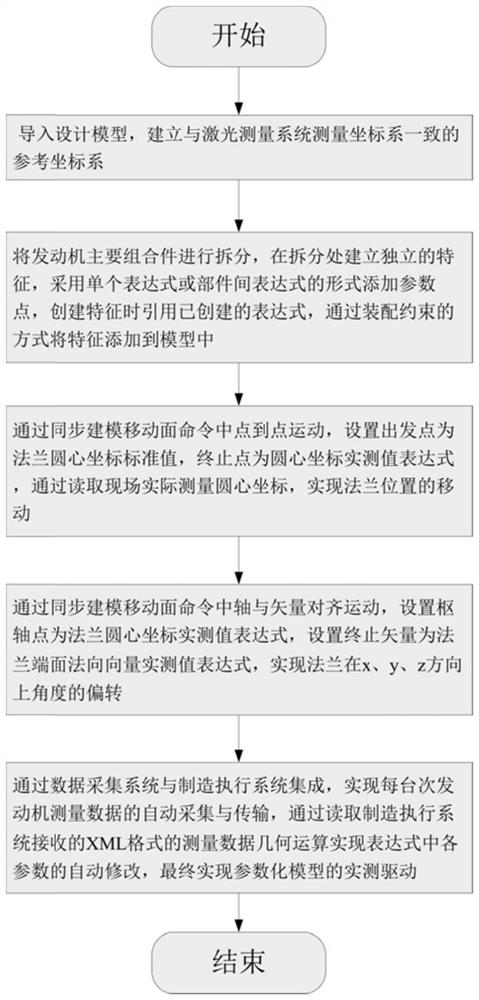

[0038] The invention relates to a method for constructing a parametric model of a liquid rocket engine, which combines parametric modeling technology with reverse engineering to realize that the parametric characteristics of the model driven by receiving the measurement data of the laser measurement system are consistent with the actual state of the engine, and is used for subsequent research based on the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com