Device and method for automatically detecting flow of transmission pump

An automatic detection device and automatic detection technology, applied in the field of transmission pumps, can solve the problems of inability to meet fixed sampling frequency, occupation of manpower, material resources, working time constraints, etc., to avoid inaccurate calculation results, improve measurement accuracy, and improve measurement accuracy. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

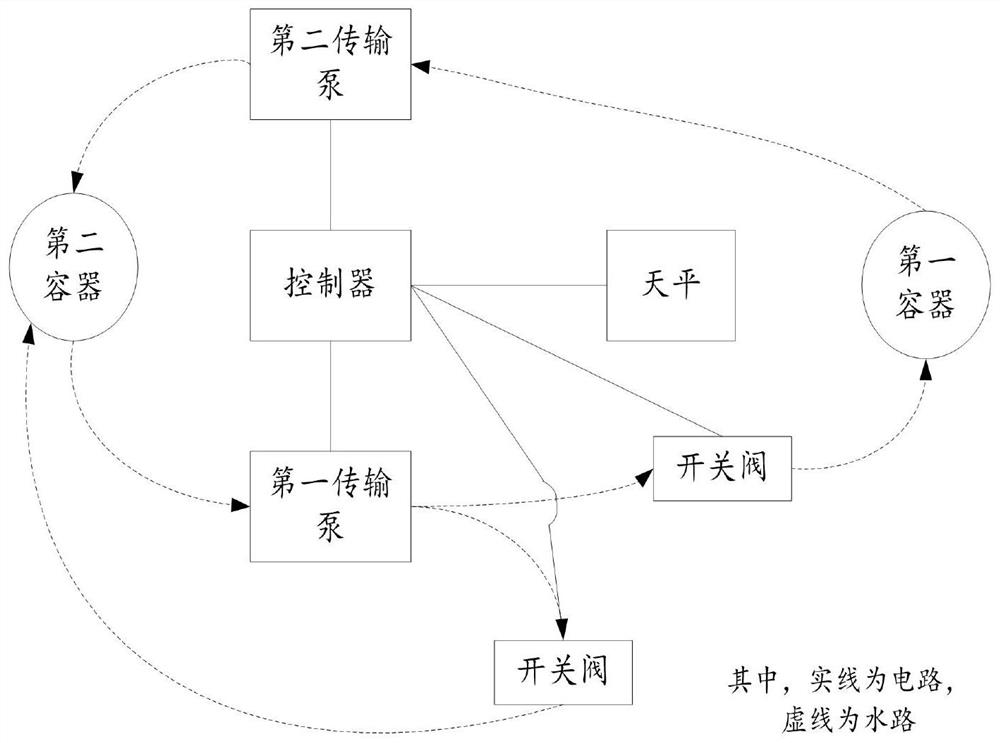

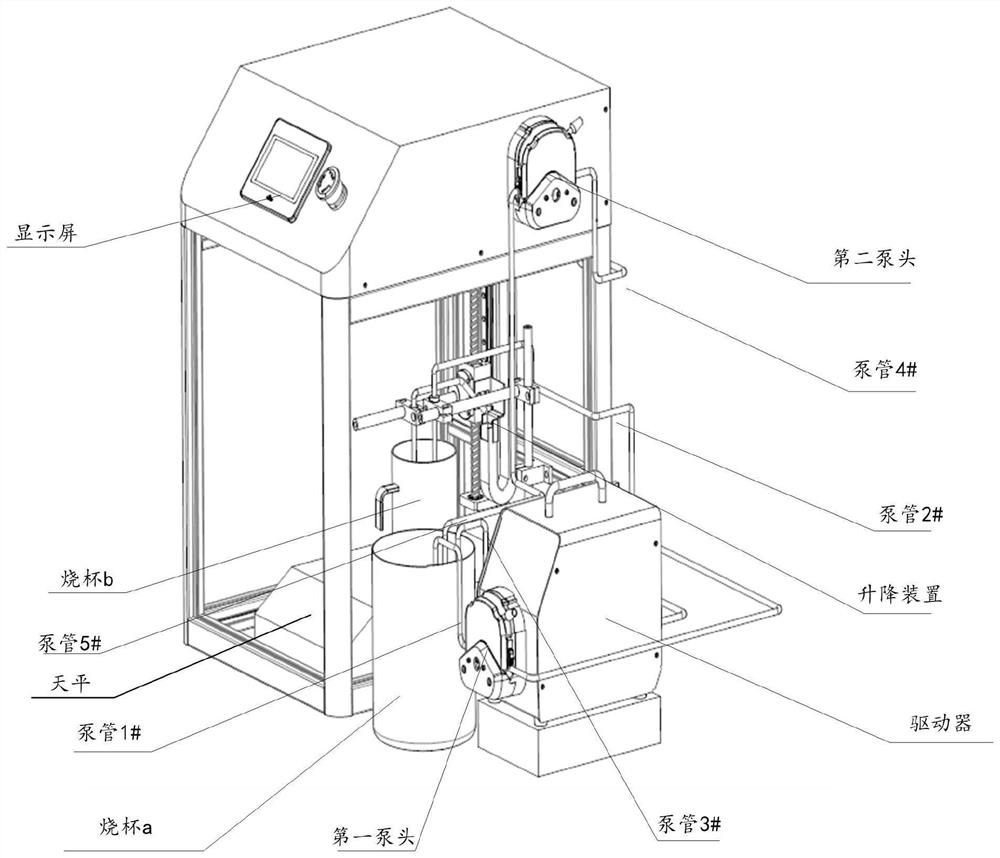

[0041] The present application provides an automatic flow detection device for a transmission pump, including: a controller, a first pipeline, a first transmission pump, a first container and a balance, the inlet of the first pipeline is connected to the liquid input container, and the first A first outlet of a pipeline is connected to the first container, wherein the controller controls the balance to weigh the first container and record data, and the first pipeline is installed on the first transmission pump.

[0042] In this scheme, the controller can be understood as a device that controls other components, it can be an integrated controller, or it can be a controller composed of modules capable of realizing multiple functions. In this solution, the controller can control the start and stop of the first transfer pump, and control the data measurement and data recording of the balance.

[0043] A transfer pump can be understood as a pump body that transfers fluids, such as...

Embodiment 2

[0051] In the first embodiment, only a quantitative transmission path is added, and a balance is used to measure the fluid in the first container. The first transfer pump continues to transfer, but the capacity of the first container is fixed after all and cannot accommodate more fluid, so this embodiment also adds a pumping pipeline, which is to discharge the fluid in the first container at regular intervals to prevent the fluid from overflowing The first container will cause environmental pollution. In addition, it will also cause errors in measurement data.

[0052] The pumping pipeline in this embodiment includes: a second pipeline, a second transfer pump and a second container, the inlet of the second pipeline is connected to the first container, and the outlet of the second pipeline is connected to the The second container, the second pipeline is installed in the second transfer pump, and the second transfer pump is connected with the controller.

[0053] In this circui...

Embodiment 3

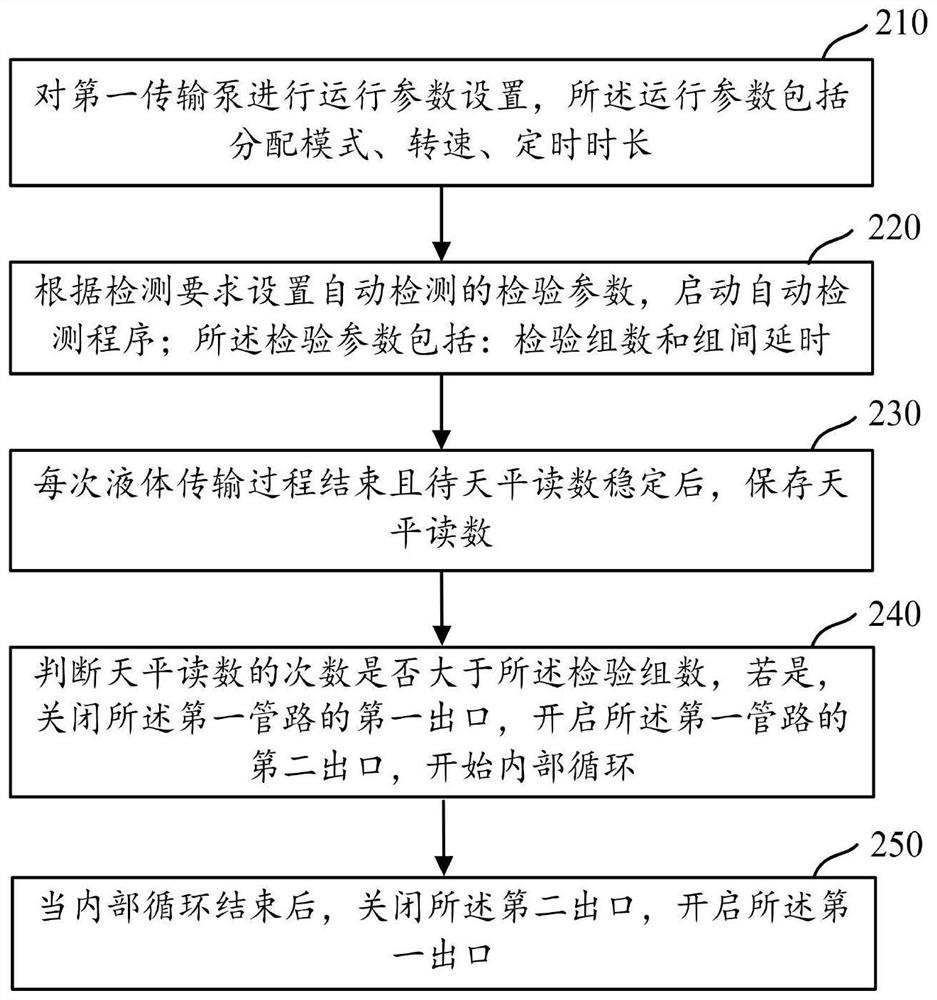

[0058] When testing the peristaltic pump, it is also necessary to measure the stability of the peristaltic pump, that is, whether the accuracy of the peristaltic pump will decrease after long-term continuous operation. This measurement requires long-term quantitative testing and does not need to obtain all measurement data. , such as every 2 hours, 4 hours or every 24 hours.

[0059] In response to this requirement, this embodiment also sets up a continuous circulation pipeline, that is, the pipeline inlet and pipeline outlet of the first transfer pump are placed in a container, so that the fluid transferred by the first transfer pump is always in the same The flow in the container, which can keep the peristaltic pump running normally, can also eliminate the need to measure the transmitted fluid data.

[0060] It should be noted that when the continuous circulation pipeline is running, the quantitative transmission pipeline is stopped. Therefore, in this embodiment, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com