PVC yoga mat and preparation method thereof

A yoga mat and resin paste technology, which is used in mats, sports accessories, gymnastics equipment, etc. that absorb sports vibration, can solve the problems of easy precipitation of plasticizers and poor resilience, and achieve good environmental protection, high wear resistance, Long-lasting effect of resilience and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

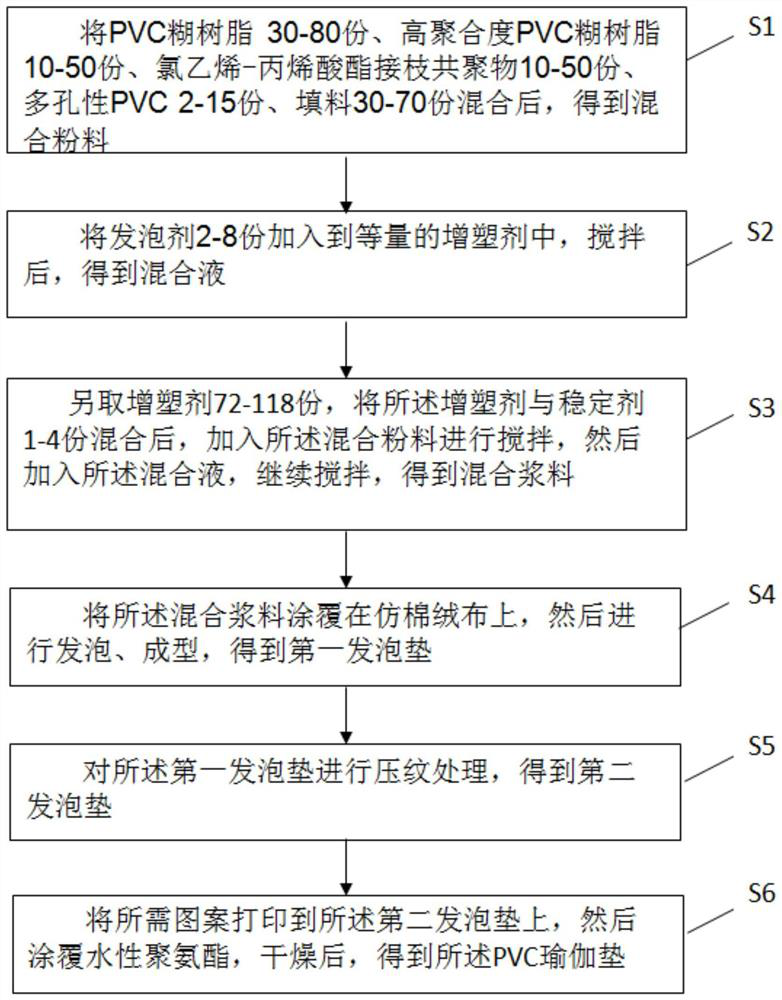

Method used

Image

Examples

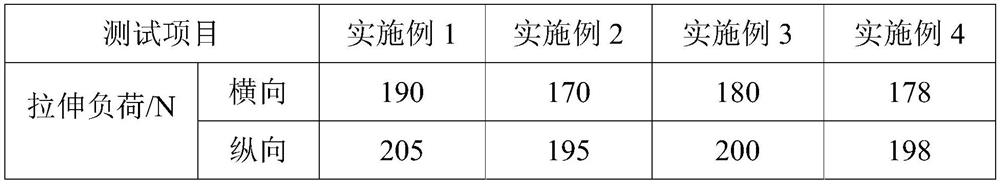

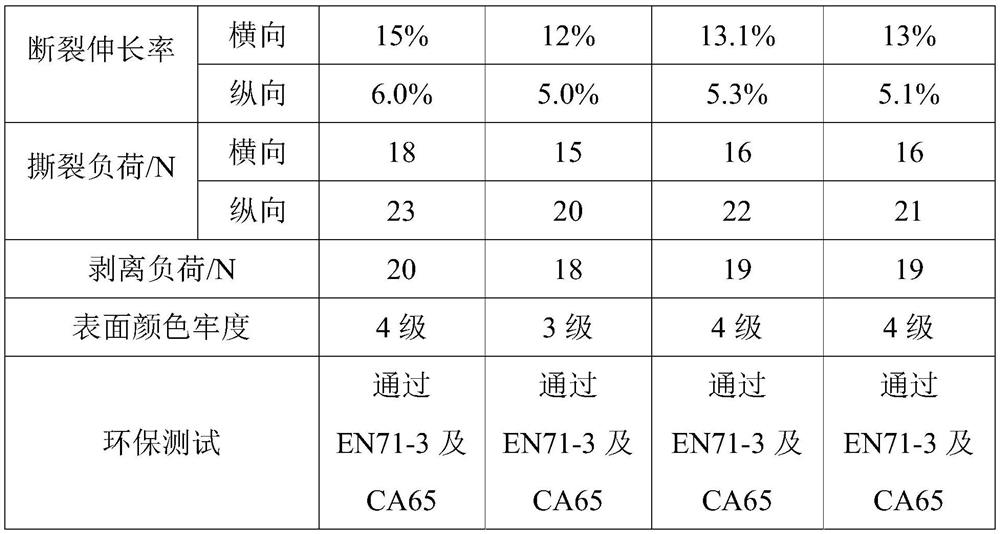

Embodiment 1

[0075] 80 parts of 1311 (PVC paste resin), 50 parts of P-80 (high degree of polymerization PVC paste resin), 50 parts of VK-710 (vinyl chloride-acrylate copolymer), 15 parts of S100 (porous PVC), 1250 mesh After mixing 70 parts of heavy calcium, stir in a blender for 3 minutes to obtain a mixed powder;

[0076] Add 8 parts of azodicarbonamide to the same amount of dioctyl terephthalate, and stir in a mixer for 3 hours to obtain a mixed solution;

[0077] Take another 112 parts of dioctyl terephthalate, mix the dioctyl terephthalate with 4 parts of 3031 (potassium zinc stabilizer) and stir in the mixer, and slowly add the mixed powder in the stirring state material, continue to stir, and after reaching 64°C, add the mixed solution, and continue to stir for 3 minutes to obtain a mixed slurry;

[0078] at 1500g / m 2 The surface density of the mixed slurry is coated on the hairy surface of the imitation cotton flannelette, and foamed in the furnace body at a speed of 6m / min at a ...

Embodiment 2

[0082] 30 parts of 1311 (PVC paste resin), 10 parts of P-80 (high degree of polymerization PVC paste resin), 10 parts of VK-710 (vinyl chloride-acrylate copolymer), 2 parts of S100 (porous PVC), 1250 mesh After mixing 30 parts of heavy calcium, stir in a blender for 3 minutes to obtain a mixed powder;

[0083] Add 2 parts of azodicarbonamide to the same amount of dioctyl terephthalate, and stir in a mixer for 1 hour to obtain a mixed solution;

[0084] Take another 78 parts of dioctyl terephthalate, mix the dioctyl terephthalate with 1 part of 3031 (potassium zinc stabilizer) and stir in the mixer, and slowly add the mixed powder under stirring material, continue to stir, and after reaching 64°C, add the mixed solution, and continue to stir for 3 minutes to obtain a mixed slurry;

[0085] at 1500g / m 2 The surface density of the mixed slurry is coated on the hairy surface of the imitation cotton flannelette, and foamed in the furnace body at a speed of 8m / min at a temperature...

Embodiment 3

[0089] 50 parts of 1311 (PVC paste resin), 30 parts of P-80 (high degree of polymerization PVC paste resin), 30 parts of VK-710 (vinyl chloride-acrylate copolymer), 18 parts of S100 (porous PVC), 1250 mesh After mixing 50 parts of heavy calcium, stir in a blender for 3 minutes to obtain a mixed powder;

[0090] Add 5 parts of foaming agent to the same amount of dioctyl terephthalate, and stir in a mixer for 1 hour to obtain a mixed solution;

[0091] Take another 110 parts of dioctyl terephthalate, mix 3 parts of said dioctyl terephthalate with 3031 (potassium zinc stabilizer) and stir in a blender, and slowly add the mixed powder under stirring material, continue to stir, and after reaching 64°C, add the mixed solution, and continue to stir for 3 minutes to obtain a mixed slurry;

[0092] at 1500g / m 2 The surface density of the mixed slurry is coated on the hairy surface of the imitation cotton flannelette, and foamed in the furnace body at a speed of 7m / min at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com