Surface modification method of plastic centrifugal tube for extracting biological sample

A technology for biological samples and centrifuge tubes, applied in the coating and other directions, can solve the problems of inability to ensure protein molecules, poor surface modification uniformity, and dead corners of centrifuge tube modification, and achieve good dipping treatment effect, high uniformity, and low Adsorbent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for surface modification of plastic centrifuge tubes for extracting biological samples, said method comprising the steps of:

[0059] Degreasing and cleaning the plastic centrifuge tube, the plastic centrifuge tube is made of PP material, the length is 8cm, and the maximum diameter is 6mm;

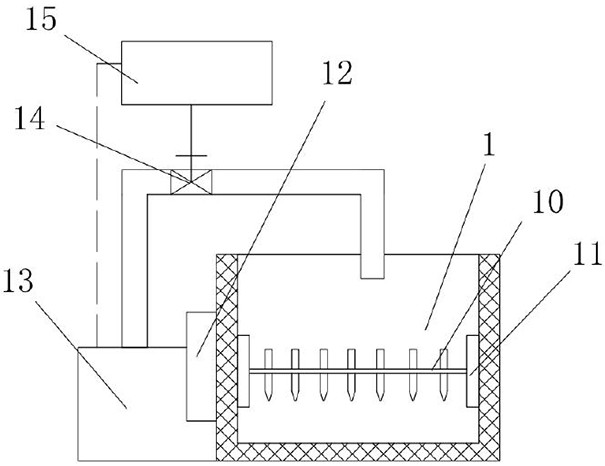

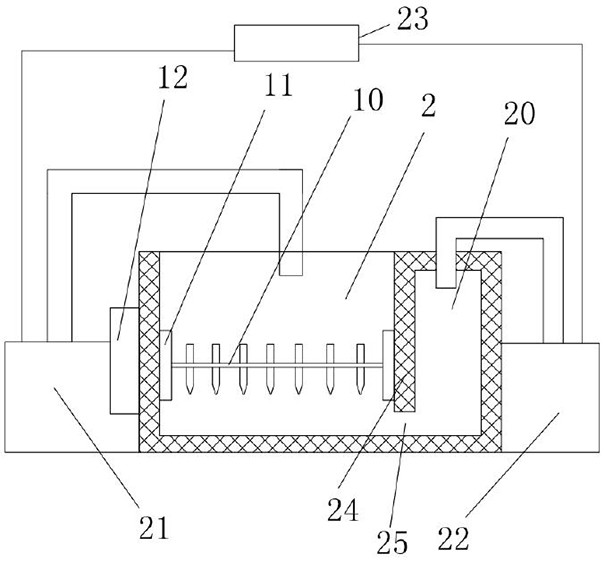

[0060] Prepare an acetone solution containing 2.5-3wt% benzophenone as a hydroxylation solution, and add the hydroxylation solution to figure 1 The impregnation chamber 1 of the hydroxylation equipment shown, the plastic centrifuge tube is placed on the rotating fixture 10 and placed on the mounting seat 11 in the impregnation chamber 1 and immersed in the hydroxylation solution for hydroxylation reaction, and the installation is driven by the rotating device 12 Seat 11 rotates intermittently; rotate forward at a speed of 10 rpm for 4 minutes, then stop the rotation and make the opening of the plastic centrifuge tube downward for 40 seconds, then continue to rotate in the o...

Embodiment 2

[0064] The surface modification method of a plastic centrifuge tube for extracting biological samples provided in this example is basically the same as that in Example 1, the difference is that:

[0065] When carrying out hydroxylation treatment, also use figure 1 The shown equipment pressurizes the reaction system, and the applied air pressure is 8kPa greater than the external atmospheric pressure.

Embodiment 3

[0067] The surface modification method of a plastic centrifuge tube for extracting biological samples provided in this example is basically the same as that in Example 1, the difference is that:

[0068] During the hydroxylation treatment, a stepping device is used to control the plastic centrifuge tube to reciprocate linearly in the hydroxylation solution along the length direction of the rotating fixture 10. The moving distance is 18mm, and the time for one reciprocating movement is 12s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com