Industrial wastewater catalytic oxidation equipment based on Internet of Things

A technology of catalytic oxidation of industrial wastewater, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of inaccurate control of wastewater pH value, and achieve the effect of accurately controlling pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

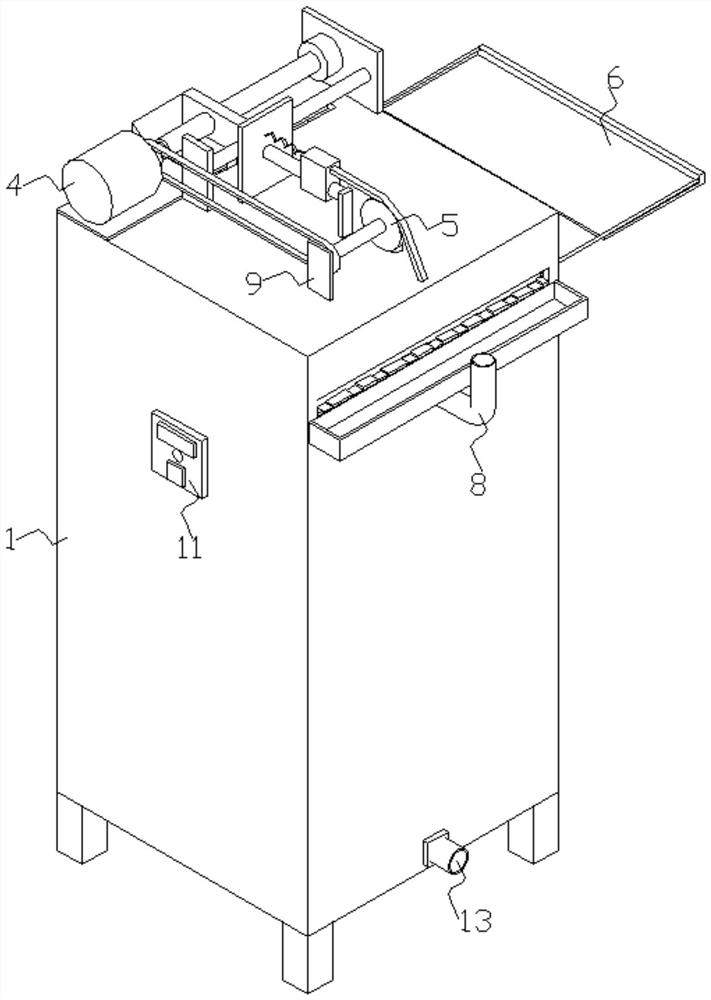

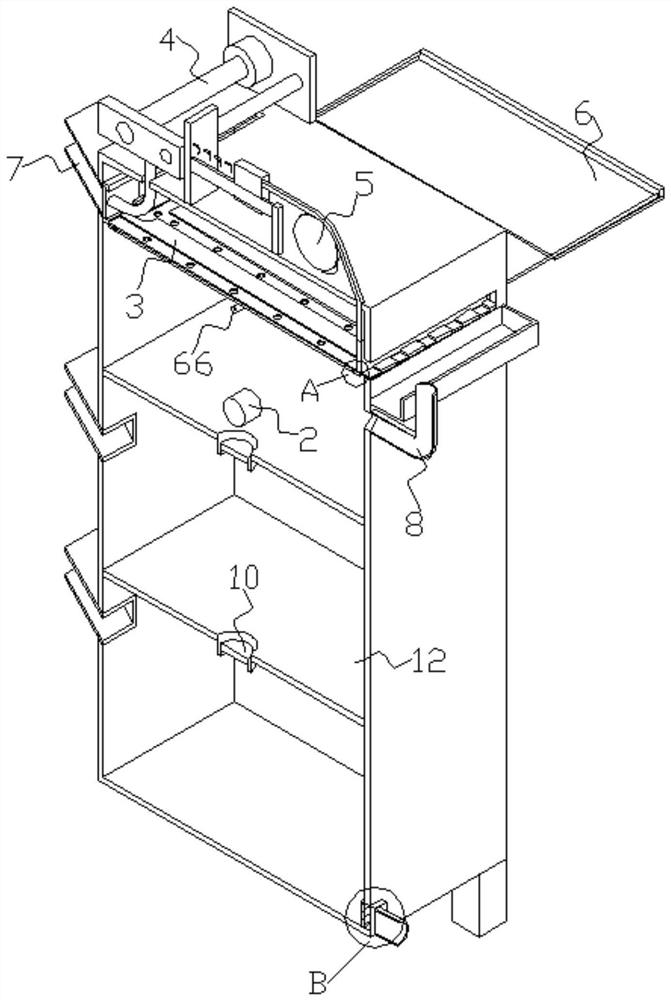

[0028] Refer Figure 1-8 , The embodiment of the invention is provided, an electrically connected industrial wastewater catalyzed oxidation apparatus, including the box 1 and the drainage mechanism 3, and the opening and closing control mechanism 4;

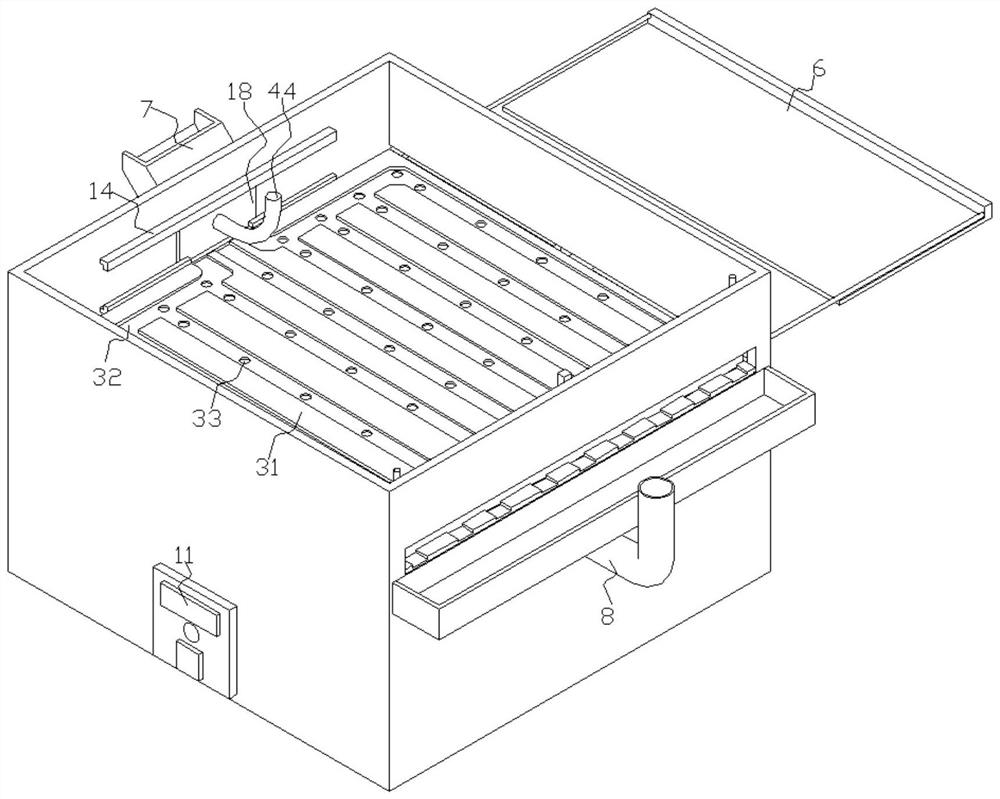

[0029] Two partition plate 12 is mounted in the casing 1, and the casing 1 is separated from top to three sets of processing chambers, and the partition plate 12 is used to divide the interior space of the box body 1, and the three sets of processing cavities are opened. In the feed port 7, the three sets of feed port 7 are used to place different additives, and two slide rails 14 are mounted in the upper handling cavity, and the two rails 14 are located on the feed port 7, respectively. The movable plate 18 is placed between the two rails 14, and the movable plate 18 is used to enclose the uppermost feed port 7, and the opening and closing control mechanism 4 is fixed to the outside of the casing 1, and the opening and closing contro...

Embodiment 2

[0036] In Example 1, since the drainage plate 31 is inclined, and the oblique lower end leads to the casing 1, the partial acid liquid is flowed through the drainage plate 31 to the casing 1, in order to prevent waste, refer to the external flow of the acid liquid during adjusting the pH. Figure 1-8 In this embodiment, a shut-off mechanism 5 is included.

[0037] The intercepting mechanism 5 is attached to the outside of the casing 1, and the shutoff mechanism 5 is connected to the output shaft of the motor 41 through the transmission mechanism 9.

[0038] The shutoff mechanism 5 includes two fixed plates 51, a fixing lever 52, a movable block 53, a spring 54, a sprocket 55, a support rod 56, a chain 57, and a shut-off plate 58, and two fixed plates 51 are mounted above the outer portion of the box 1. One end of the fixing lever 52 is fixed to one of the fixed plates 51, and the other end is fixed to the other fixing plate 51, and the movable block 53 is disposed between the two f...

Embodiment 3

[0044] Due to the closure of the uppermost feed port 7, the excess time flows through the drainage plate 31 to the acid collecting mechanism for a certain period of time. At this time, some acid solution is still dropped through the flow hole 33. In the wastewater, affect the pH of the wastewater, resulting in the next waste water pH value, affecting the treatment effect, in order to collect the poly acid solution, no additional acid re-enter the pH of the wastewater, refer to the reference Figure 1-8 In this embodiment, a closure mechanism 6 is included.

[0045] The closure mechanism 6 is attached to the top handling cavity is attached, and the closure mechanism 6 is located below the drainage plate 31.

[0046] The closure mechanism 6 includes a long plate 61, a closure plate 62, two rods 63, a carrier plate 65, an electric telescoping rod 66, and a connecting plate 67, and the closure plate 62 is active under the drainage plate 31, and the closure plate 62 is used to close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com