Automatic control system for neutralization process in gelatin production

A technology of automatic control and production process, applied in the direction of electrical program control, preparation of animal glue or gelatin, comprehensive factory control, etc., can solve problems affecting bone quality, waste of water resources, increase of production cost, etc., and achieve economic benefits , Improve production efficiency and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

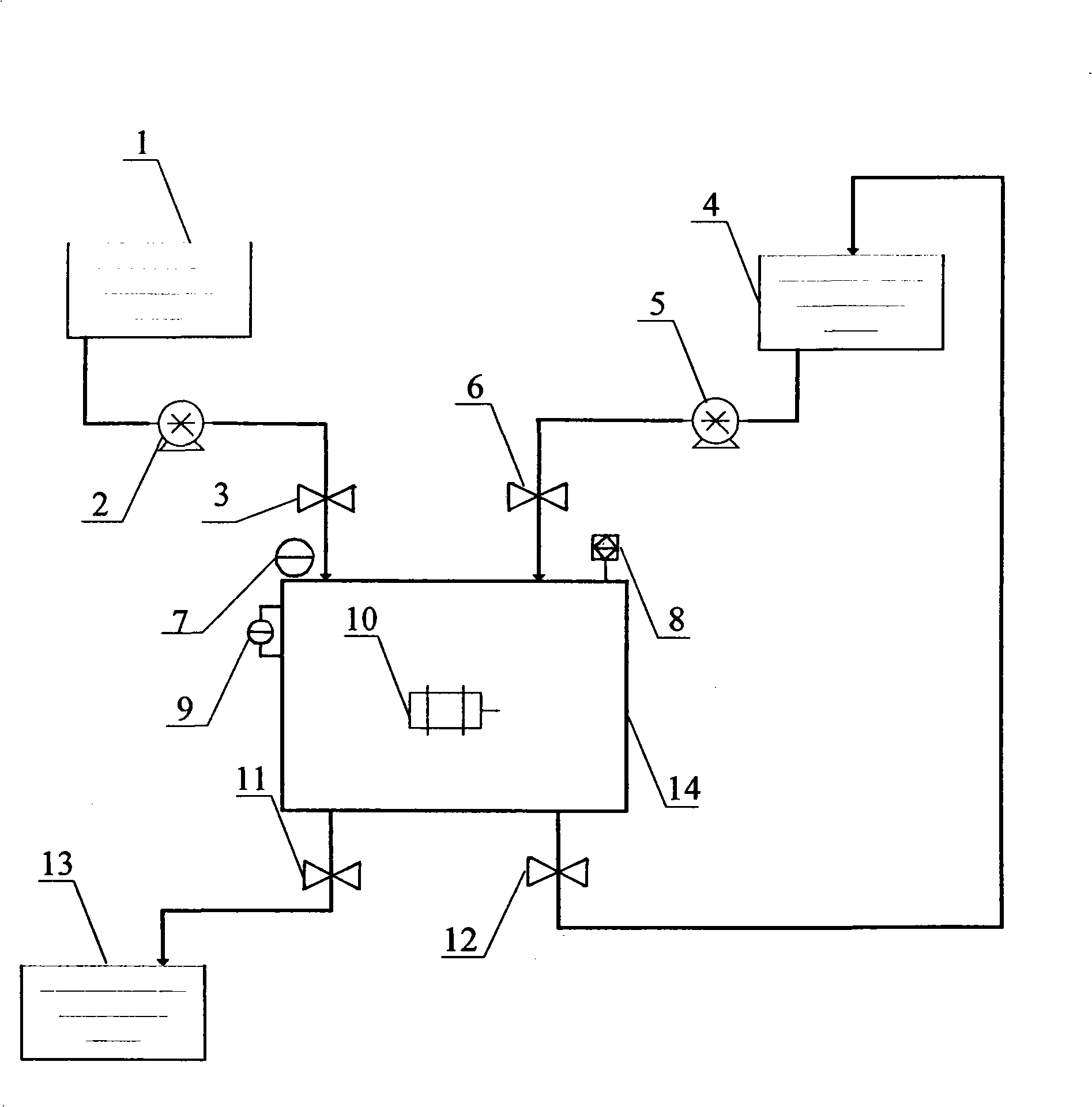

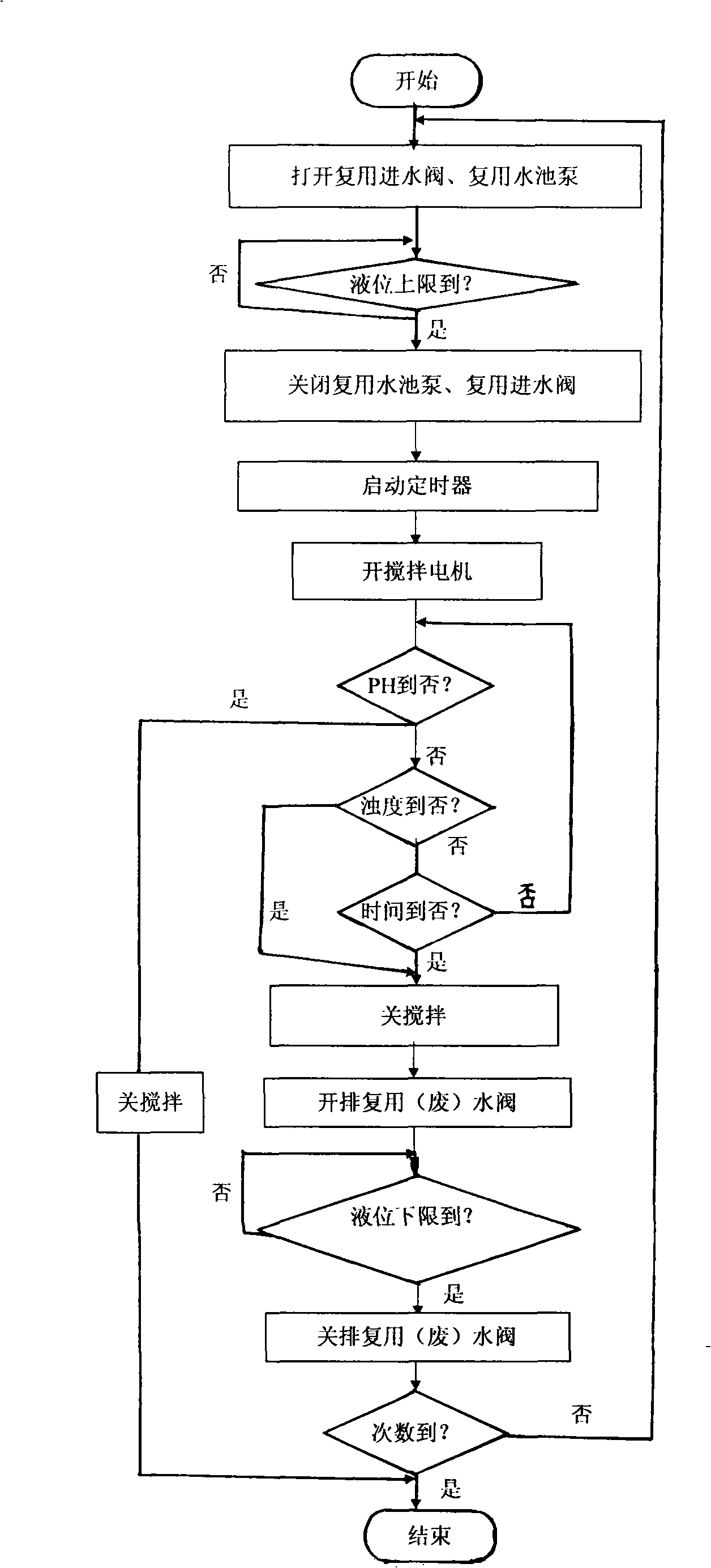

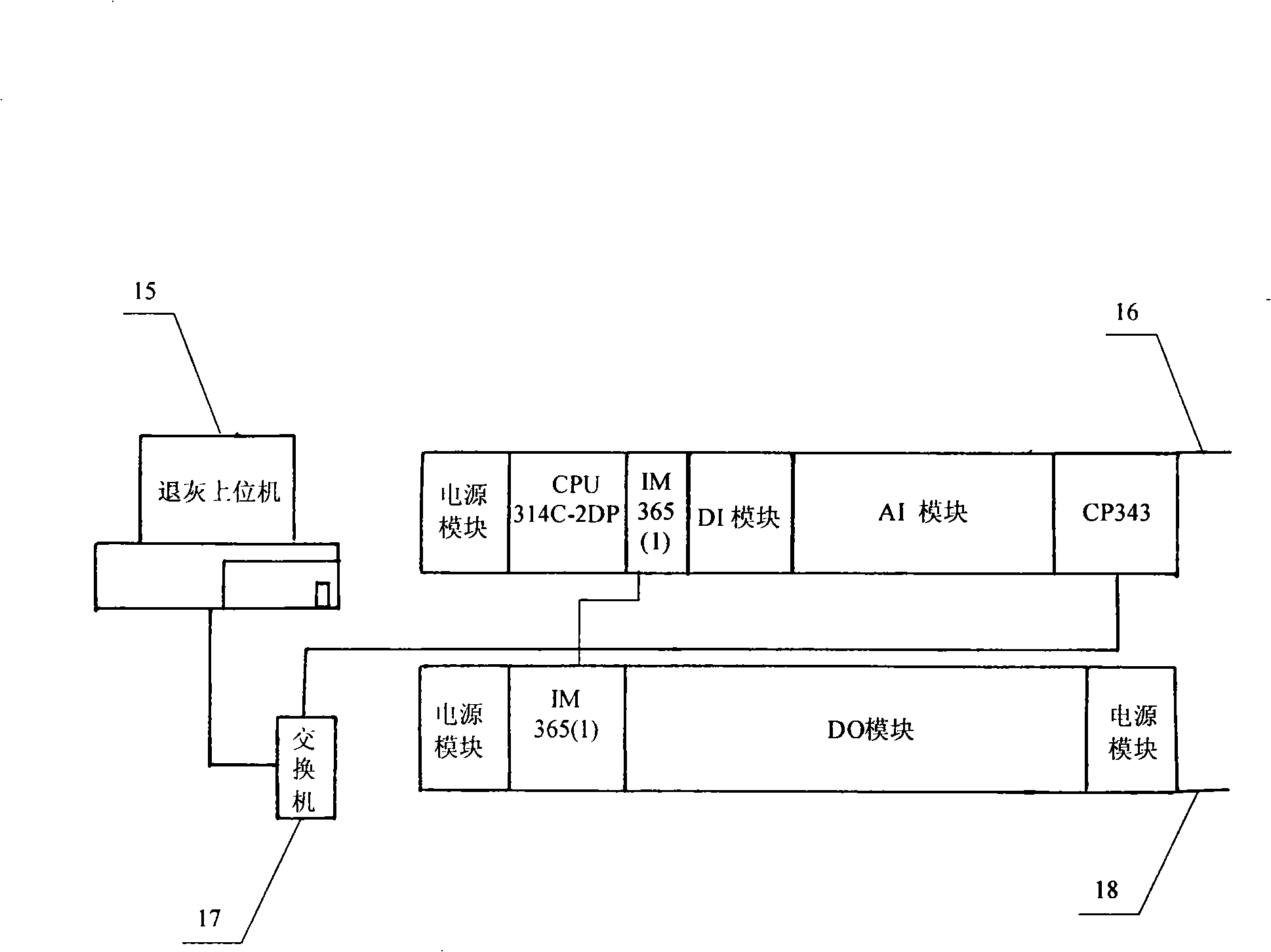

[0010] Such as figure 1 As shown, the automatic control system of the ash removal process includes an ash removal tank 14, a mechanical stirring device 10 is arranged in the ash removal tank 14, and a liquid level sensor 7, a pH sensor 8 and a turbidity sensor 9 are correspondingly arranged in the ash removal tank. On the pool 14, the neutralization and reuse water pool 1 is connected with the ash removal pool 14 through the neutralization and reuse water pump 2 and the neutralization and reuse water inlet valve 3, and the ash removal and reuse water pool 4 is connected with the ash removal and reuse water pump 5 and the ash removal The reuse water inlet valve 6 is connected with the ash removal pool 14, the waste water tank is connected with the ash removal tank 14 through the waste water valve 11, and the ash removal reuse pool 4 is connected with the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com