Thermal chemical sulfur-iodine circulating hydrogen production full-process method and device

A full-process, thermochemical technology, applied in chemical instruments and methods, inorganic chemistry, hydrogen, etc., can solve problems such as energy consumption, catalyst poisoning, energy waste, etc., to reduce investment and energy consumption, prevent I2 precipitation, and improve conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

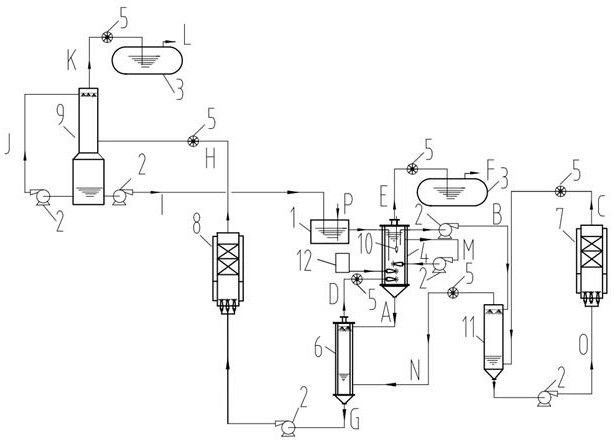

Image

Examples

Embodiment 1

[0052] The initial temperature in the Bunsen reaction separation tower is 85°C under normal pressure, and the feed in the tower is 10 mol H 2 SO 4 , 20 mol HI, 10 mol SO 2 ,20mol I 2 ,120mol water. SO after 1.5h reaction 2 The conversion rate reaches 95%. The two phases were left to stand for 20 minutes to separate, and respectively entered into H 2 SO 4 system and HIx system. h 2 SO 4 Phase and HIx phase outlet temperatures were 85 °C.

[0053] h 2 SO 4 The phase composition is H 2 SO 4 4.7 mol / kg, HI 0.34 mol / kg, I 2 0.115 mol / kg, H 2 O 25.9 mol / kg. Liquid phase mixture from H 2 SO 4 Spraying at the top of the concentration tower, during the descent with 2 SO 4 SO in decomposition tower 2 and O 2 When the high-temperature steam meets, the liquid water is quickly vaporized and taken away. High temperature mixed gas (450-500°C) from H 2 SO 4 The top of the concentration tower enters the HIx purification and concentration tower through the action of a...

Embodiment 2

[0061] The initial temperature in the Bunsen reaction separation tower is 85°C under normal pressure, and the feed in the tower is 10 mol SO 2 ,34 mol I 2 ,105mol water. SO after 1.5h reaction 2 The conversion rate reaches 95%. The two phases were left to stand for 20 min to separate, and respectively entered into H 2 SO 4 system and HIx system. h 2 SO 4 Phase and HIx phase outlet temperatures were 85 °C.

[0062] h 2 SO 4 The phase composition is H 2 SO 4 4.6 mol / kg, HI 0.3 mol / kg, I 2 0.07 mol / kg, H 2 O 27.4 mol / kg. Liquid phase mixture from H 2 SO 4 Spraying at the top of the concentration tower, during the descent with 2 SO 4 SO in decomposition tower 2 and O 2 When the high-temperature steam meets, the liquid water is quickly vaporized and taken away. High temperature mixed gas (450-500°C) from H 2 SO 4 The top of the concentration tower enters the HIx purification and concentration tower through the action of a fan. h 2 SO 4 Concentration towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com