Automatic forking method of unmanned forklift

A technology of unmanned forklifts and forklifts, applied in non-electric variable control, two-dimensional position/channel control, vehicle position/route/height control, etc. Goods damage and other problems, to improve the accuracy of fork picking, avoid damage to goods and forklifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

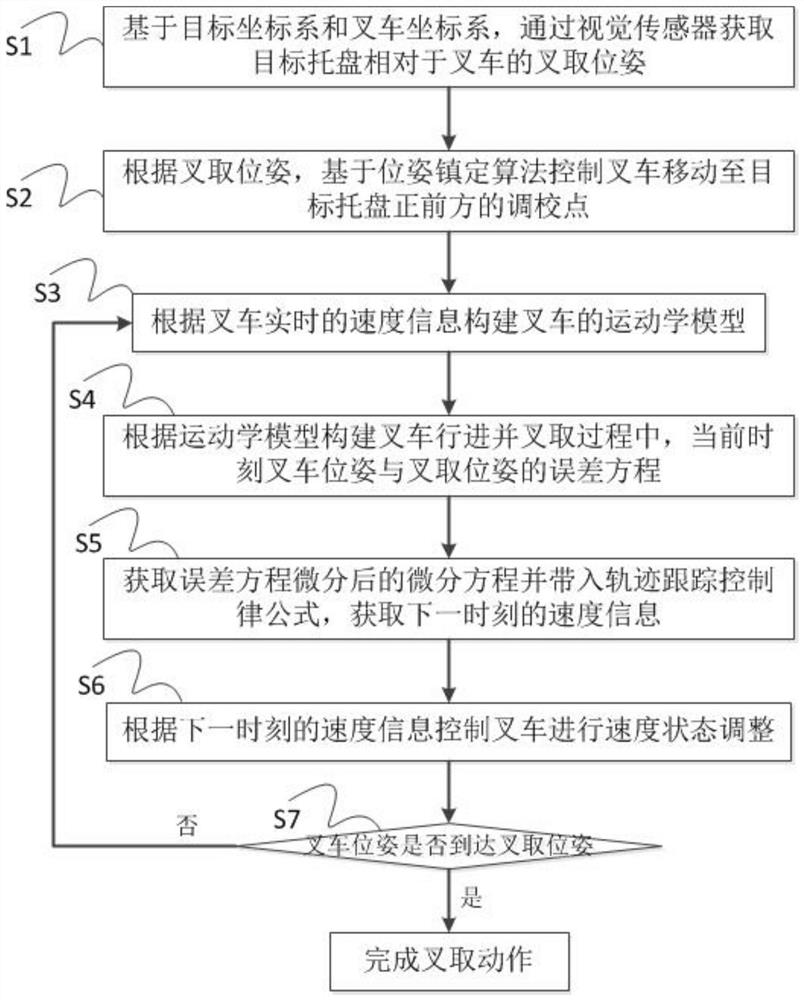

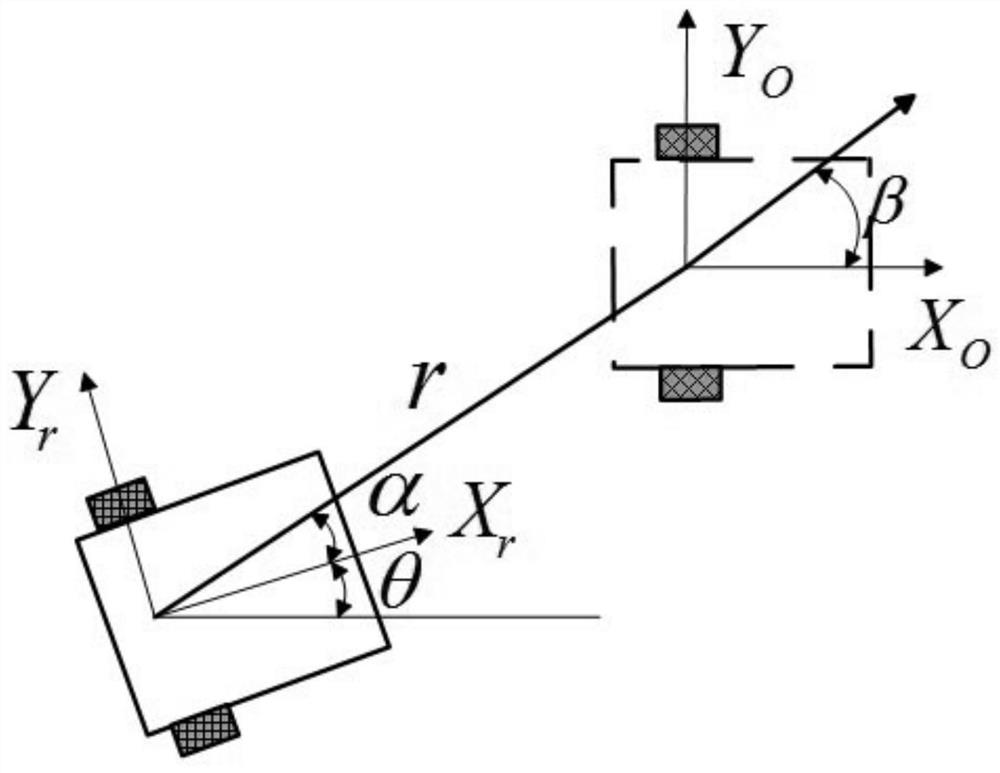

[0046] In order to enable unmanned forklifts to better align the pallet jacks when facing irregularly placed pallets, and avoid damage to forklifts and goods caused by forklift collisions, such as figure 1 As shown, the present invention proposes an automatic fork picking method for an unmanned forklift, which uses the inertial origin of the target pallet as the target origin to construct a target coordinate system, and uses the forklift wheel axle center point as the forklift origin to construct a forklift coordinate system, including steps:

[0047] S1: Based on the target coordinate system and the forklift coordinate system, the fork-taking pose of the target pallet relative to the forklift is obtained through the visual sensor;

[0048] S2: Control the forklift to move to the adjustment point directly in front of the target pallet based on the pose stabilization algorithm according to the fork pose;

[0049] S3: Construct the kinematics model of the forklift according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com