A high-pressure nano-homogenizer with multiple accumulators to stabilize oil pressure

A nano-homogenizer and accumulator technology, applied in accumulator devices, mechanical equipment, fluid pressure actuating devices, etc., can solve problems such as oil pulsation, reduce oil pressure pulsation and ensure stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

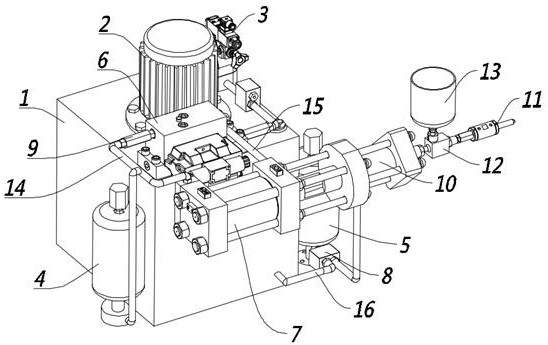

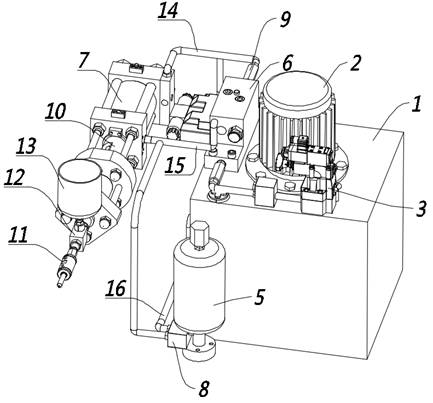

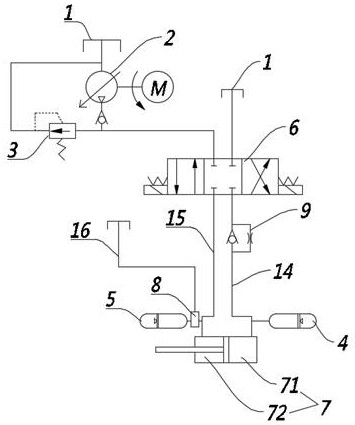

[0022] This embodiment provides a high-pressure nano-homogenizer with multiple accumulators to stabilize oil pressure, which mainly solves the problem of oil pulses generated when the plunger pump reciprocates.

[0023] Including oil tank 1, oil pump 2, reversing solenoid valve 6, hydraulic cylinder 7, such as figure 1 As shown, the oil pump 2 is installed on the oil tank 1 to absorb oil and deliver it to the hydraulic cylinder 7, and the reversing solenoid valve 6 is installed between the oil pump 2 and the hydraulic cylinder 7 to switch the oil flow direction. The inner cavity of the hydraulic cylinder 7 is slidably provided with a piston, and the piston divides its inner cavity into a first oil cavity 71 and a second oil cavity 72. The hydraulic rod is mounted on the piston and extends out of the hydraulic cylinder 7, and has hydraulic pressure. The inner cavity of the rod is the second oil cavity 72 , the first oil pipe 14 is connected between the first oil cavity 71 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com