Concrete curing system for tunnel with super-large cross section

A super-large cross-section and maintenance system technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problem of time-consuming and affect the construction progress, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

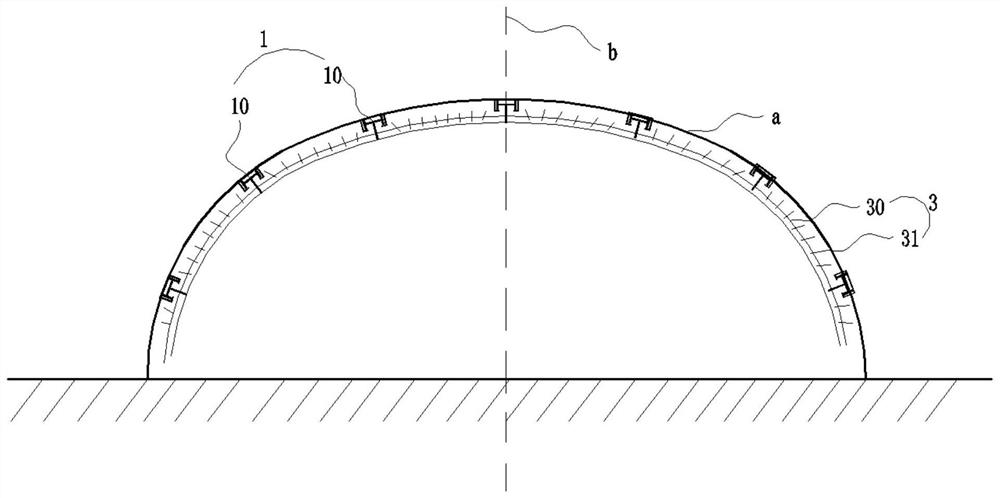

[0043] Such as Figure 1 ~ Figure 2 As shown, a super-large section tunnel concrete maintenance system, including:

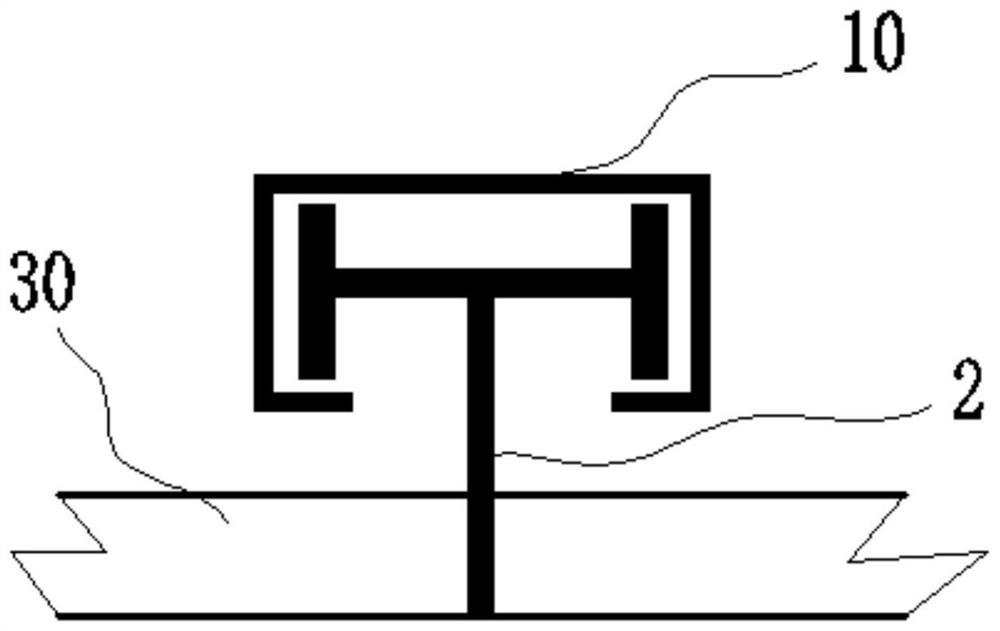

[0044] A maintenance track 1 , a sliding device 2 connected to the maintenance track 1 , and a spray device 3 connected to the sliding device 2 .

[0045] Wherein, the maintenance track 1 includes several C-shaped steel channels 10 arranged in parallel along the length direction of the tunnel. The opening of the C-shaped steel channels 10 faces downward, and the top is fixed to the poured concrete tunnel surface by expansion bolts.

[0046] The sliding device 2 is connected in the C-shaped steel channel 10 and moves along the length direction of the C-shaped steel channel 10 .

[0047] The spraying device 3 includes an arc-shaped spraying pipe 30. The spraying pipe 30 is arranged along the arc direction of the tunnel and is connected with the sliding device 2. Several spraying units 31 are arranged on the spraying pipe 30. 30 when the liquid is passed in, the ...

Embodiment 2

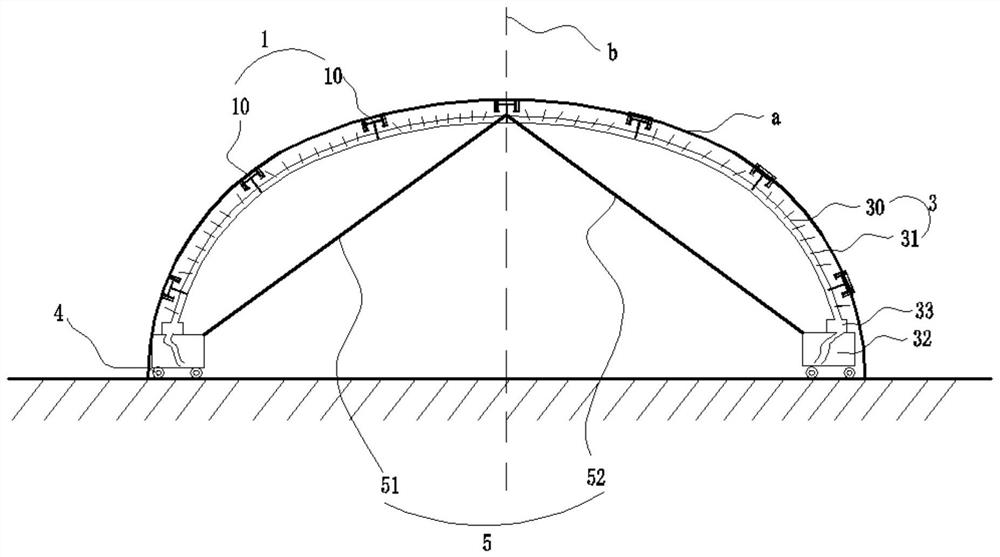

[0052] Such as Figure 3 ~ Figure 5 As shown, a super-large section tunnel concrete maintenance system includes: a maintenance track 1 , a sliding device 2 connected to the maintenance track 1 , and a spray device 3 connected to the sliding device 2 .

[0053] Wherein, the maintenance track 1 includes several C-shaped steel channels 10 arranged in parallel along the length direction of the tunnel. The opening of the C-shaped steel channels 10 faces downward, and the top is fixed to the poured concrete tunnel surface by expansion bolts.

[0054] The sliding device 2 is connected in the C-shaped steel channel 10 and moves along the length direction of the C-shaped steel channel 10 .

[0055] The spraying device 3 includes an arc-shaped spraying pipe 30. The spraying pipe 30 is arranged along the arc direction of the tunnel and is connected with the sliding device 2. Several spraying units 31 are arranged on the spraying pipe 30. 30 when the liquid is passed in, the spray unit 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com