A fully automatic spraying mechanism for mold release agent for automatic shoe-making production line

A release agent, fully automatic technology, applied in the direction of the injection device, etc., can solve the problems of uneven spraying of the release agent, poor release effect, low work efficiency, etc., and achieves ingenious structure, good uniformity and good continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

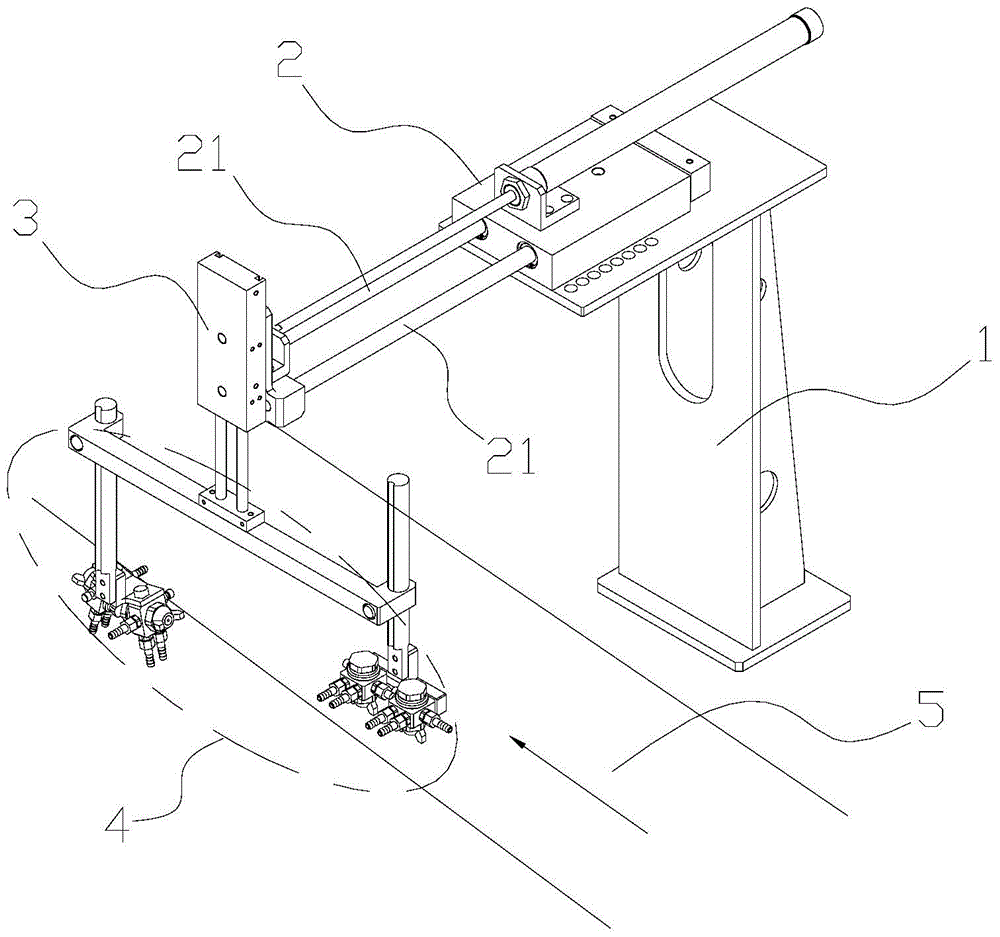

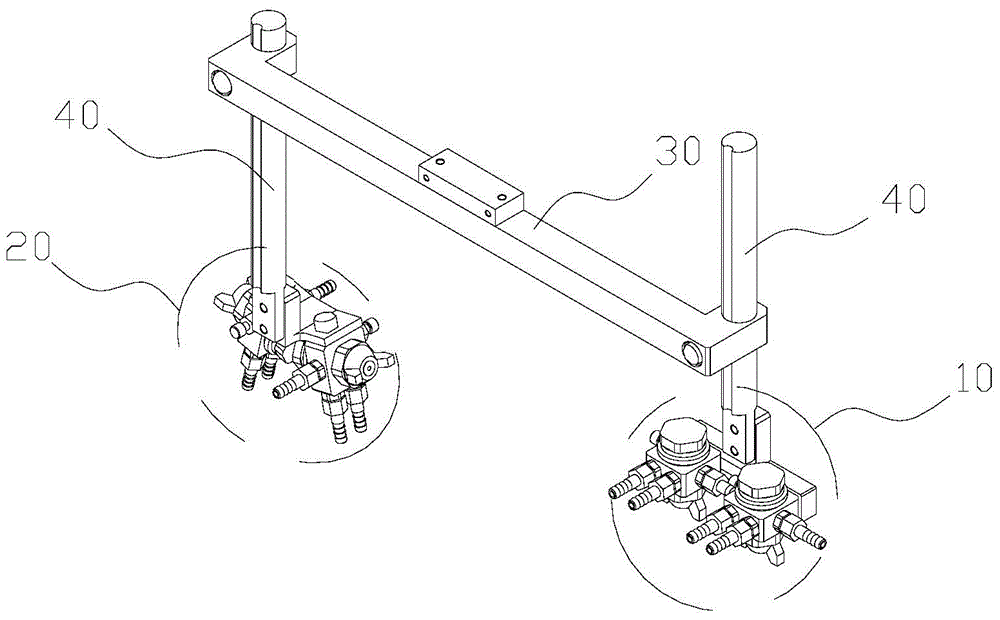

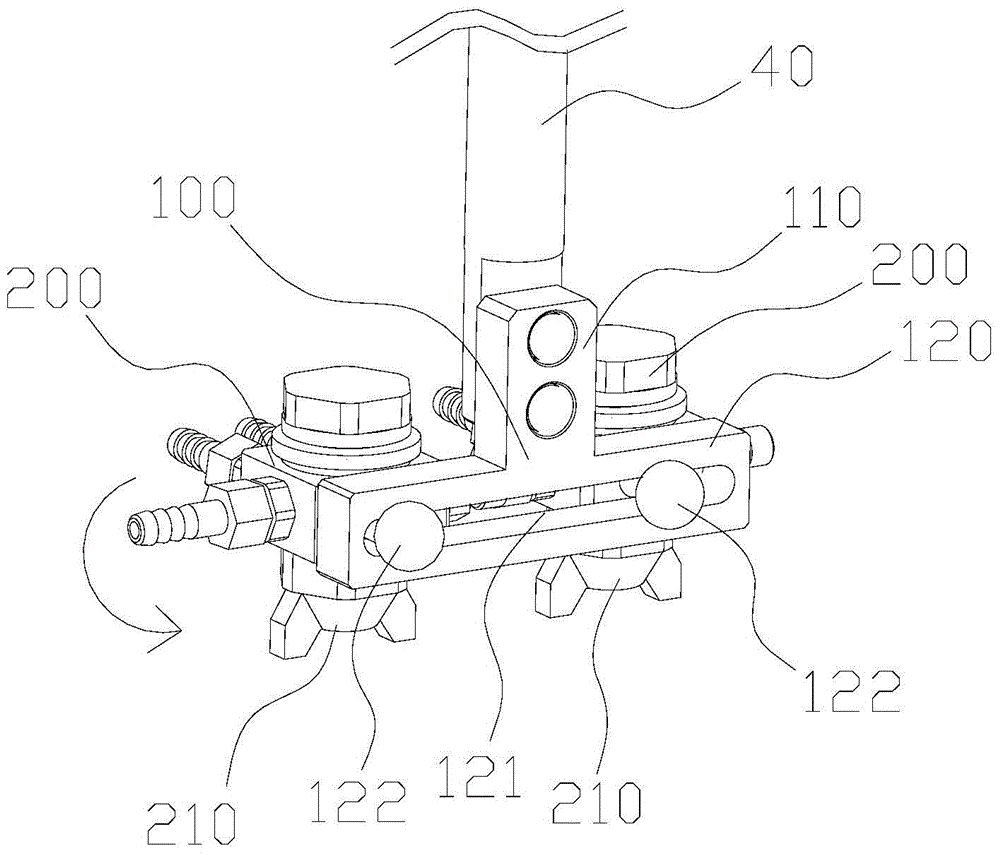

[0028] The invention discloses a fully automatic spraying mechanism for release agent used in an automated shoe production line. figure 1 As shown, it includes a base 1, a lateral movement mechanism 2 and a longitudinal movement mechanism 3 installed on the base 1, and a nozzle structure 4 connected to the lateral movement mechanism 2 and the longitudinal movement mechanism 3. In practical applications, see figure 1 , Both the lateral movement mechanism 2 and the longitudinal movement mechanism 3 adopt air cylinder mechanisms. The base 1 is fixed on one side of the conveyor belt 5, the lateral movement mechanism 2 is fixedly installed on the base 1, and the lateral movement mechanism 2 is also provided with a support guide rod 21. The cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com