Downhole hydraulic vibration assisted casing running and well cementation integrated combination tool and using method thereof

A combined tool and hydraulic vibration technology, applied in drilling equipment and methods, wellbore/well components, vibration generating devices, etc. The problem of uneven vibration distribution, etc., can improve the replacement efficiency, ensure the cementing quality, and achieve the effect of good drillability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

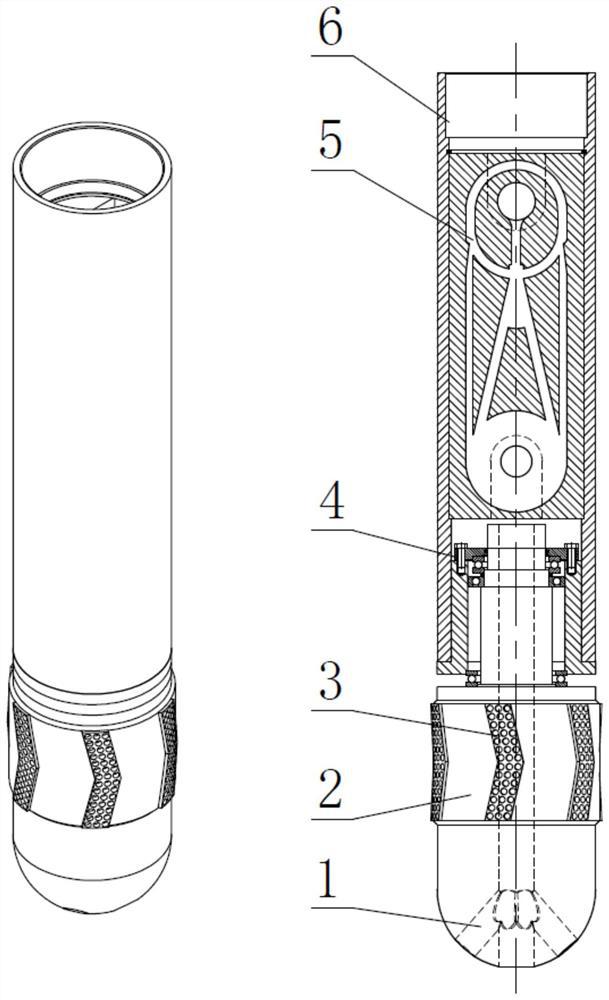

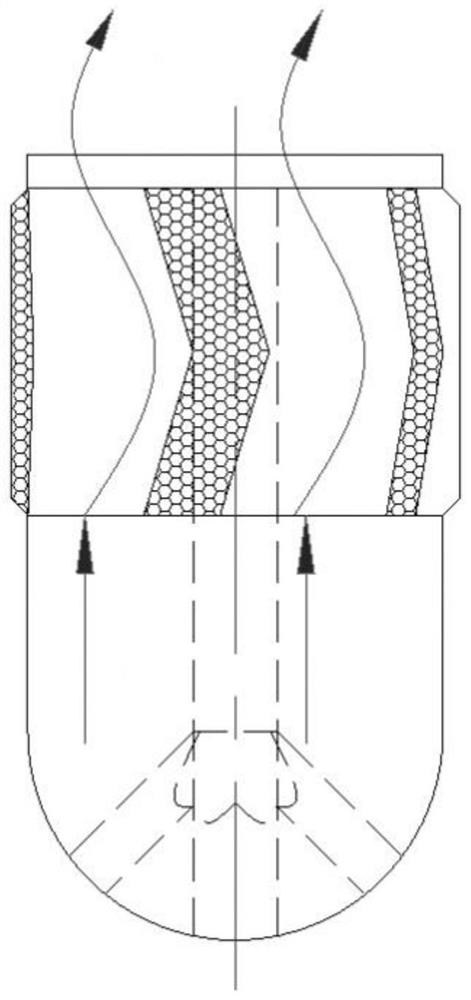

[0035] Such as figure 1 As shown, it is a schematic structural diagram of the integrated tool for casing running and cementing provided by the present invention, including a shoe jet module 1 that can guide casing running, can change the fluid flow path and play the role of reaming The reaming and drainage module, the turbine assembly 4 that is installed in the casing to drive the shoe-introduction jet module 1 through hydraulic circulation, the reaming and drainage module to rotate together, the hydraulic vibration module 5 with a unique self-exciting swirl cavity structure, and can be combined with The inner threaded joint 6 that matches the casing.

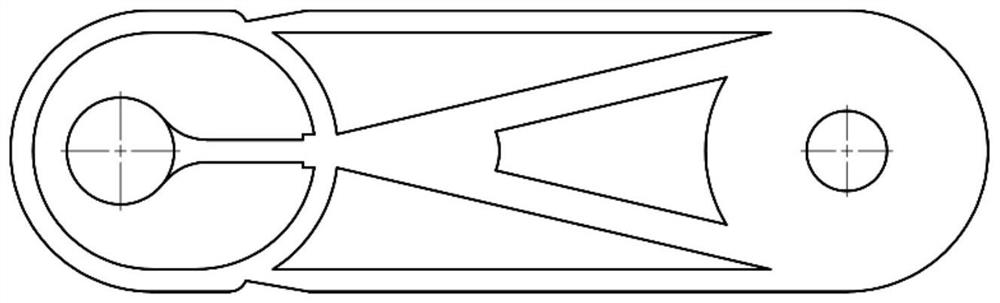

[0036] In the combined casing and cementing integrated tool assisted by downhole hydraulic vibration of the present invention, the hydraulic vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com