Pipeline shaft and monitoring system and construction method thereof

A technology for pipeline wells and pipelines, which is used in electrical transmission signal systems, artificial islands, measuring devices, etc., can solve the problems of complicated communication pipeline manhole structure, long construction period, poor safety, etc., so as to improve safety and stability. Low cost, not easy to lose the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

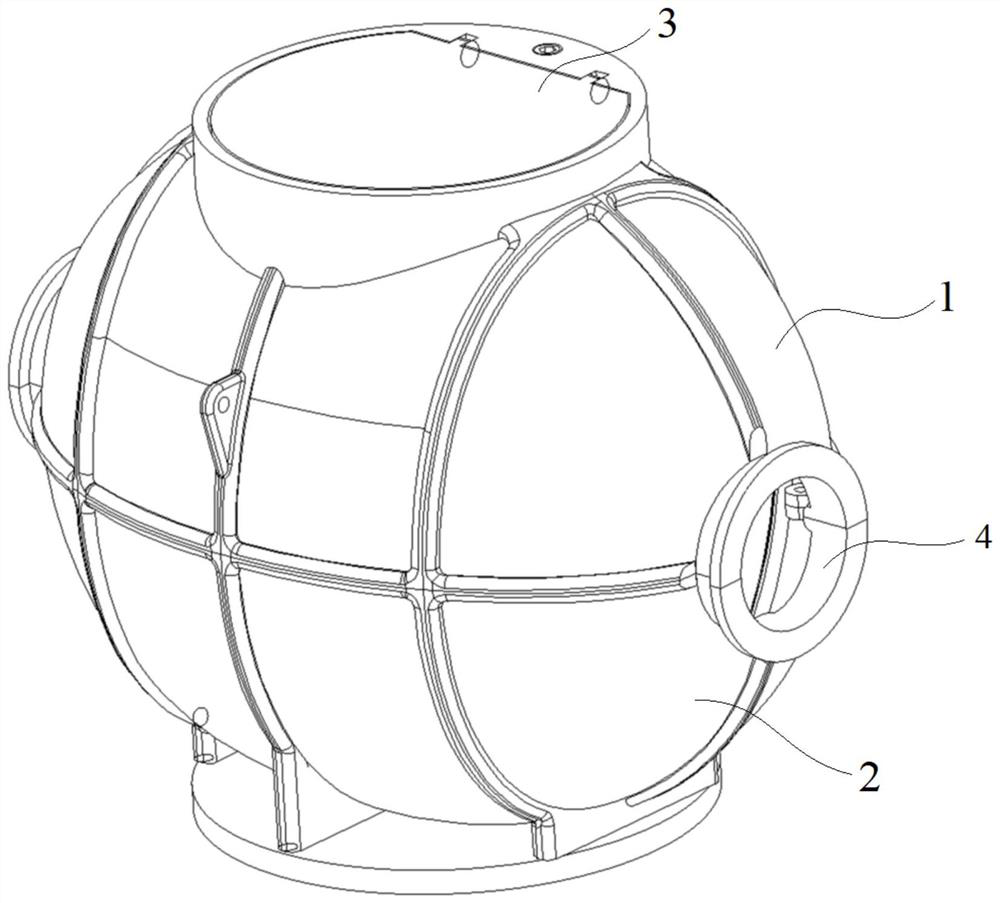

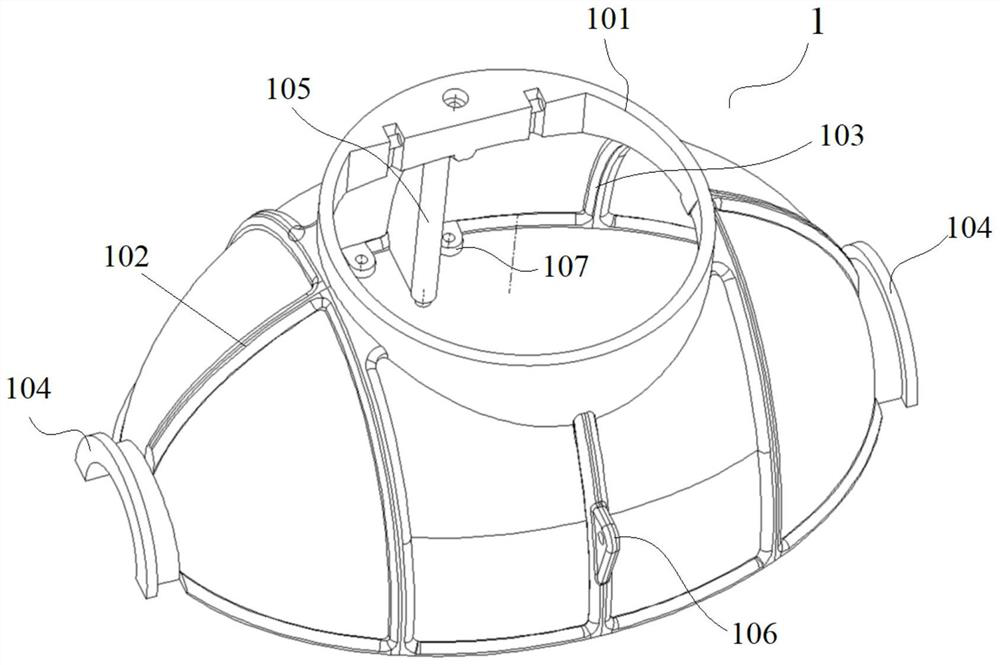

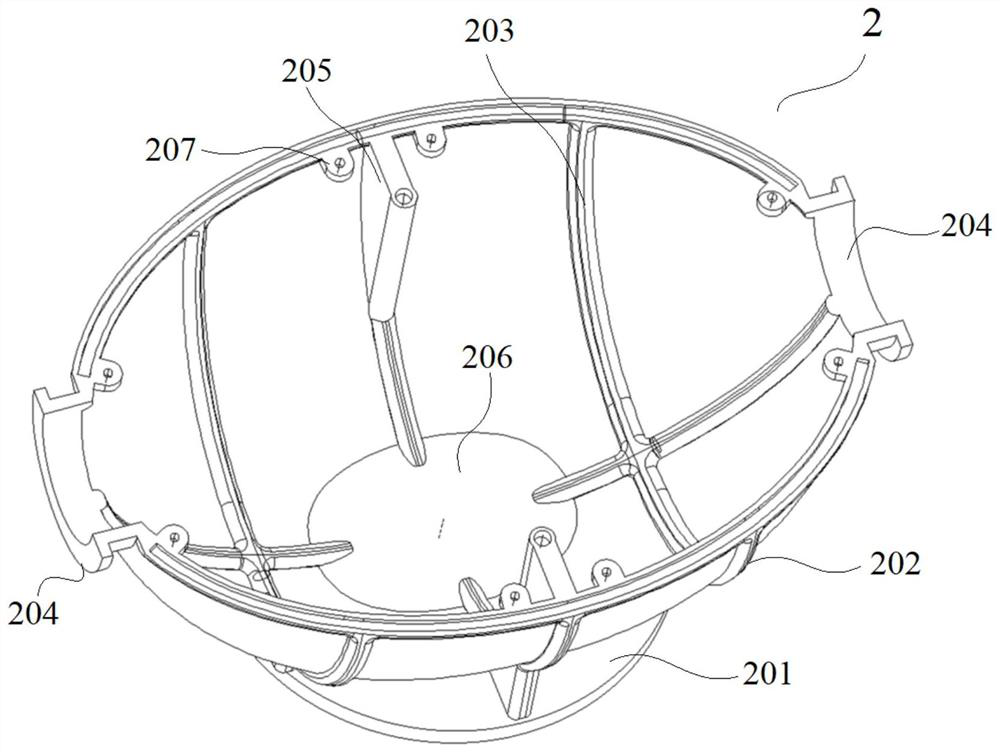

[0068] figure 1 It is a three-dimensional schematic view of the pipeline well provided in the embodiment of the present application. The pipeline well is mainly composed of upper well body 1, lower well body 2, well cover 3, bolts and other components. Both the upper well body 1 and the lower well body 2 are integrally prefabricated, and the well cover 3 is also prefabricated. The upper well body 1 and the lower well body 2 are fixed into an integrated pipeline well body by bolts, and the well cover 3 is rotatably connected with the upper well body 1, so that the installation is convenient and fast.

[0069] The upper well body 1 and the lower well body 2 are combined to form an integral pipeline well body, a cavity is formed inside the pipeline well body, and pipeline windows 4 connected with the cavity are formed at both ends of the pipeline well body, so that communication optical cables can be realized. put on. The pipeline well can be used as a communication pipeline ma...

Embodiment 2

[0115] An embodiment of the present application provides a pipeline well monitoring system, which is used to monitor the status of the above-mentioned pipeline well, including but not limited to the open state of the well cover, the state of the liquid level in the well, the state of the air in the well, and the like. Figure 10 It is a schematic structural diagram of the pipeline well monitoring system provided in the embodiment of the present application, and the pipeline well monitoring system includes:

[0116] The manhole cover monitoring module is set at the position of the manhole cover 3 on the upper well body 1, and is used to monitor the opening state of the manhole cover 3;

[0117] The liquid level sensor is installed in the pipeline well to monitor the state of the liquid level in the well;

[0118] The gas sensor is installed in the pipeline well to monitor the gas state in the well and prevent gas poisoning accidents when the staff work;

[0119] Central proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com