Open cut tunnel containing iron sand counterweight layer and construction method of open cut tunnel

A technology of open-cut tunnels and construction methods, which is applied to artificial islands, water conservancy projects, soil protection, etc., can solve the problems of site structure uplift, supporting facilities damage, tunnel structure damage, etc. The effect of a large coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

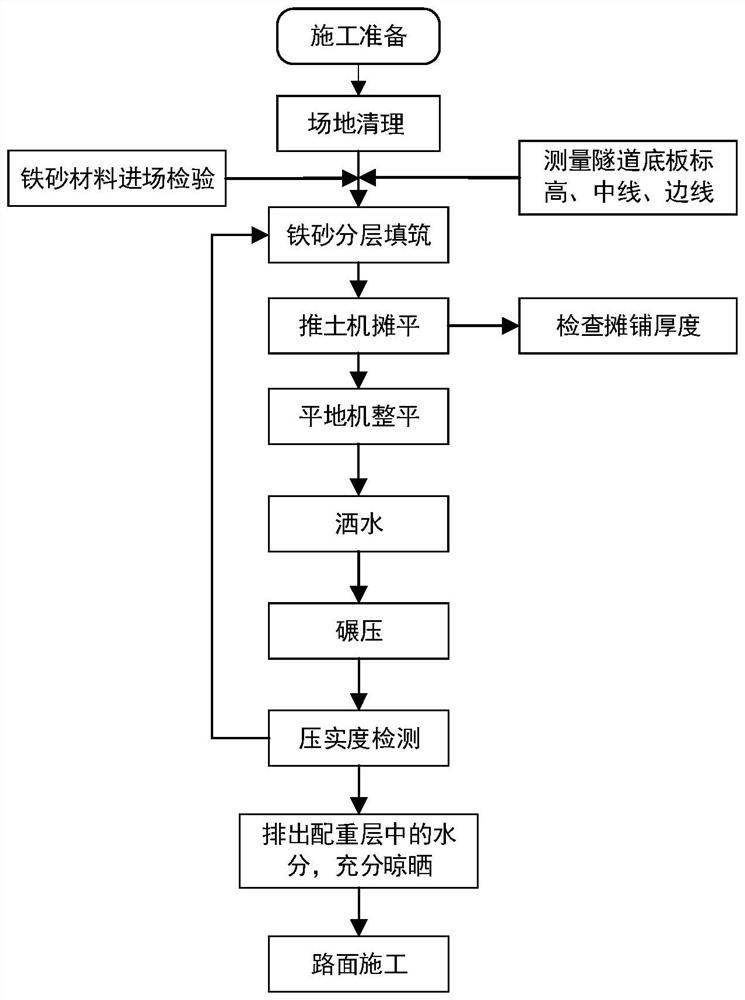

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments.

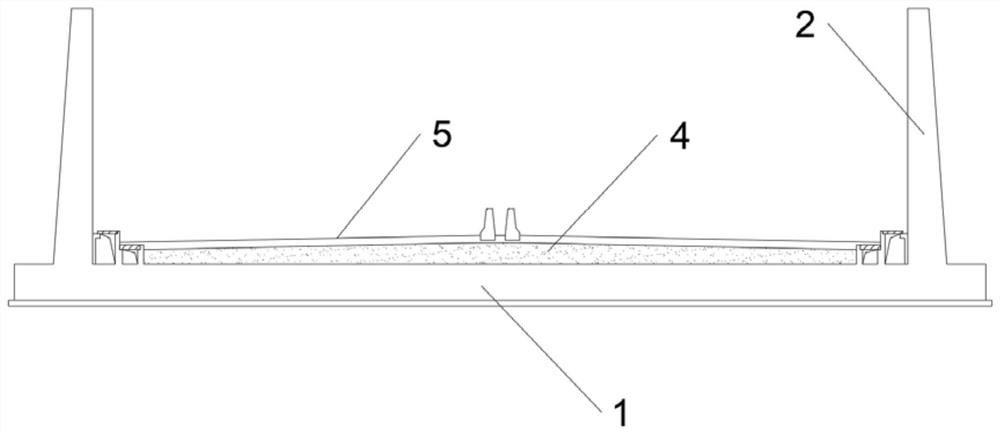

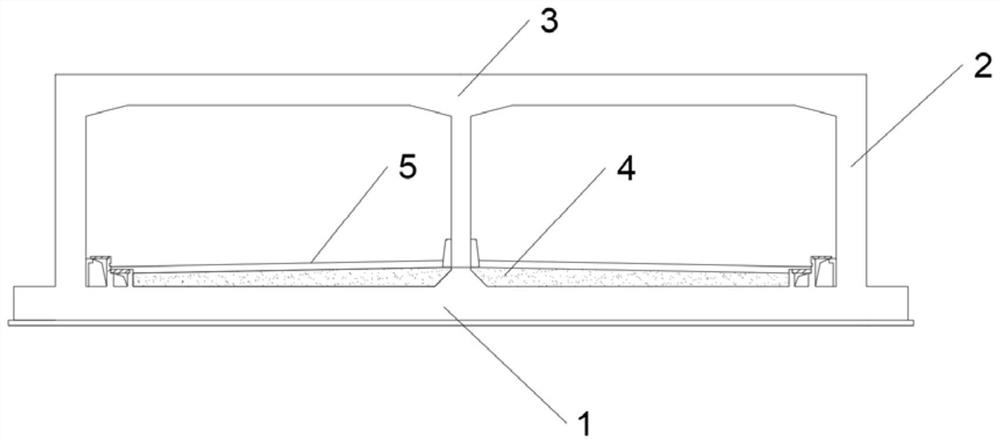

[0032] An open-cut tunnel containing an iron-sand counterweight layer, comprising a tunnel floor, a tunnel side wall, an iron-sand counterweight layer, and an internal road surface of the tunnel; the tunnel side walls are located on the left and right sides of the tunnel floor, and the iron-sand counterweight layer is laid on the upper end of the tunnel floor , The inner pavement of the tunnel is constructed on the upper end surface of the iron sand counterweight layer.

[0033] The iron sand counterweight layer covers the upper end surface of the entire tunnel floor; the iron sand counterweight layer is used for tunnel counterweight and does not participate in the tunnel structure.

[0034] An open-cut tunnel with an iron-sand counterweight layer is divided into a closed section with a tunnel roof and an open section without a tunnel roof.

[0035] In the iron s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com