Coating for power transmission line and preparation method thereof

A technology for transmission lines and coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of no resistance, increase the probability and frequency of pollution flashover of insulation equipment, poor hydrophobic migration, etc., and achieve convenient construction, low cost, and good performance. The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of coating and preparation method that transmission line is used

[0031] The component distribution ratio involved in the present embodiment 1 is the optimal value of the present invention.

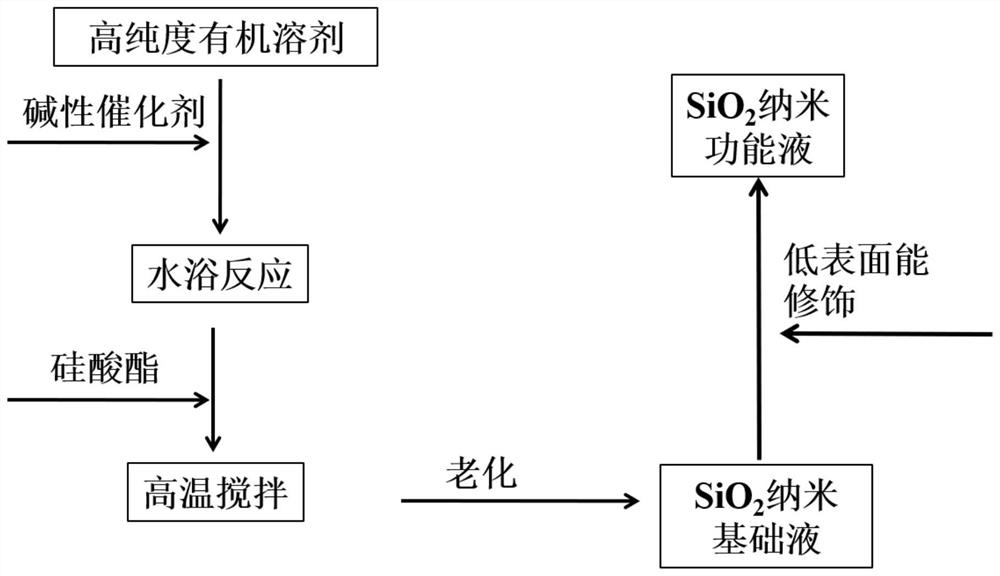

[0032] figure 1 The manufacturing process of the coating for the transmission line of the present embodiment is shown

[0033] 1. The coating used for the transmission line of this embodiment is made by mixing a primer and a top coat, and adopts a construction method of one bottom and one side.

[0034] 1) The primer is two-component, consisting of primer A component, primer B and diluent, stirred, and the dispersion process (that is, the process of dispersing a uniform paint mixture) at a stirring speed of 2000rpm or more is made into a primer.

[0035] Component A of the primer is composed of raw materials fluorosilicone resin (40%), silica filler (10%), ethyl acetate solvent (40%), dispersant (3%), defoamer (2%), It is composed of joint agent (2.5%) and ...

Embodiment 2

[0043] Embodiment 2: the coating that transmission line is used and manufacture method

[0044]The coating and manufacturing method of this embodiment 2 is basically the same as that of embodiment 1, the difference lies in the proportioning range between the components involved, which is controlled within 2% of the given weight proportion value in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com