Preparation method of sodium methyl lauroyl taurate

A technology of sodium methyl lauroyl taurate and sodium methyl taurate, which is applied to the preparation of sulfonates, preparation of organic compounds, chemical instruments and methods, etc., and can solve the problems of sodium chloride residue, complex process, Poor safety and other issues, to achieve the effect of reducing investment, simple process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

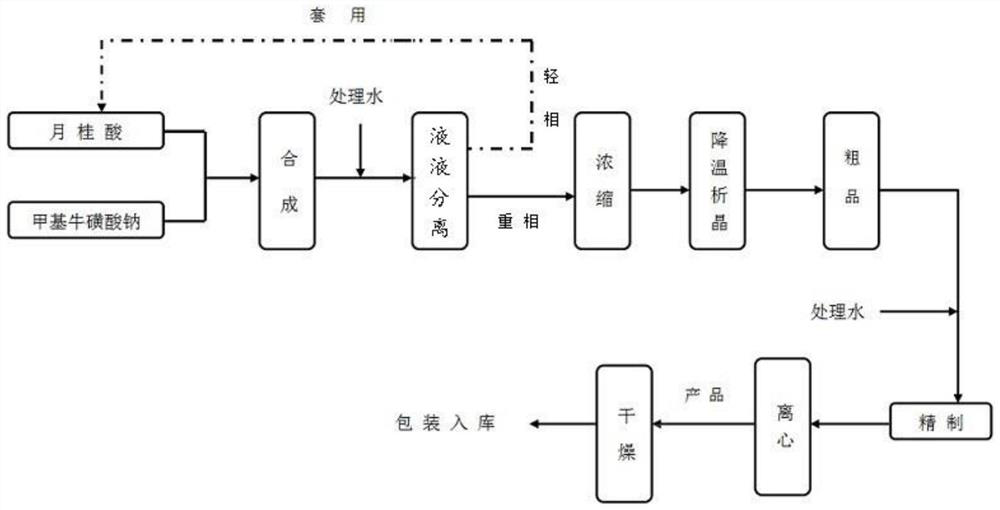

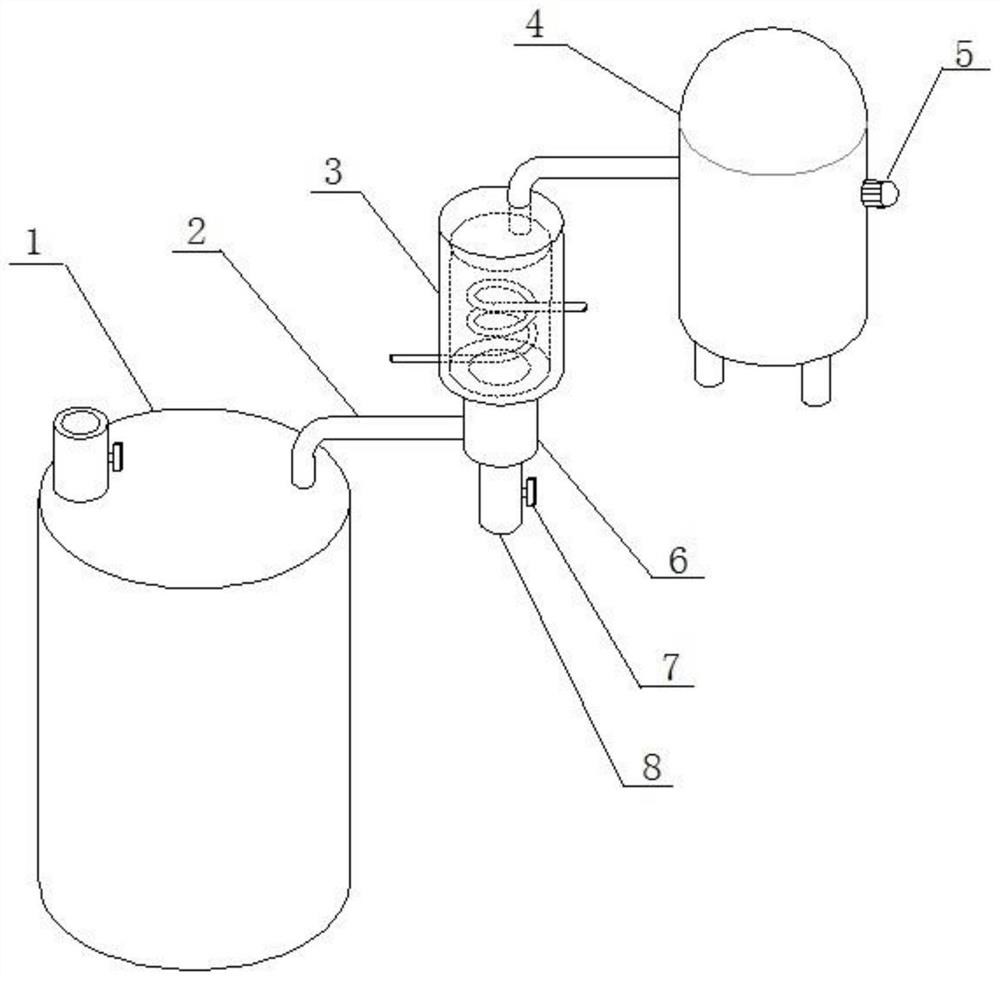

[0027] Such as figure 1 Shown, the invention provides a kind of preparation method of sodium methyl lauroyl taurate, comprising the steps:

[0028] S1. Add the designed amount of lauric acid into the reaction system, feed nitrogen to replace the air, and heat up until the lauric acid is completely melted.

[0029] S2. Control the temperature of lauric acid in the reaction system at 100-140°C, slowly inject the aqueous sodium methyl taurate solution, evaporate the water in the aqueous sodium methyl taurate solution, and control the injection speed of the aqueous sodium methyl taurate solution to avoid The reaction system produces a large amount of foam and overflows, wherein the molar ratio of lauric acid to sodium methyl taurate is 2.0-3.5:1, and the mass fraction of sodium methyl taurate is 40-60%.

[0030] S3. After the water in the sodium methyl taurate aqueous solution evaporates, the temperature of the reaction system is raised to 230-250° C. for reflux reaction for 4-8 ...

Embodiment 1

[0039] The present embodiment provides a kind of preparation method of sodium methyl lauroyl taurate:

[0040] Add lauric acid into the reaction system, replace the air with nitrogen, and raise the temperature until the lauric acid is completely melted, then control the temperature of lauric acid in the reaction system at 100-140°C, slowly inject an aqueous solution of sodium methyl taurate to evaporate methyl Moisture in the aqueous sodium taurate solution, and control the injection speed of the sodium methyl taurate aqueous solution so as not to overflow the reaction system to produce a large amount of foam, wherein, the mol ratio of lauric acid and sodium methyl taurate is 2:1, methyl The mass fraction of sodium taurate is 60%; after the injection of the aqueous solution of sodium methyl taurate is completed and the water in the aqueous solution of sodium methyl taurate is evaporated, the temperature of the reaction system is raised to 230° C. for reflux reaction for 8 hours...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of sodium methyl lauroyl taurate:

[0045] Add lauric acid into the reaction system, replace the air with nitrogen, and raise the temperature until the lauric acid is completely melted, then control the temperature of lauric acid in the reaction system at 100-140°C, slowly inject an aqueous solution of sodium methyl taurate to evaporate methyl Moisture in the aqueous sodium taurate solution, and control the injection speed of the sodium methyl taurate aqueous solution so as not to overflow the reaction system to produce a large amount of foam, wherein, the mol ratio of lauric acid and sodium methyl taurate is 2.5:1, methyl The mass fraction of sodium taurate is 55%; after the injection of the aqueous solution of sodium methyl taurate is completed and the water in the aqueous solution of sodium methyl taurate is evaporated, the temperature of the reaction system is raised to 230° C. for reflux reaction for 6 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com