Control method of scrubber

A control method and washing machine technology, which is applied to manual floor scrubbing machines, carpet cleaning machines, cleaning machines, etc., can solve problems such as reducing the service life of roller brushes, washing machine failures, and single floors, so as to prolong the service life, The effect of reducing labor intensity and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

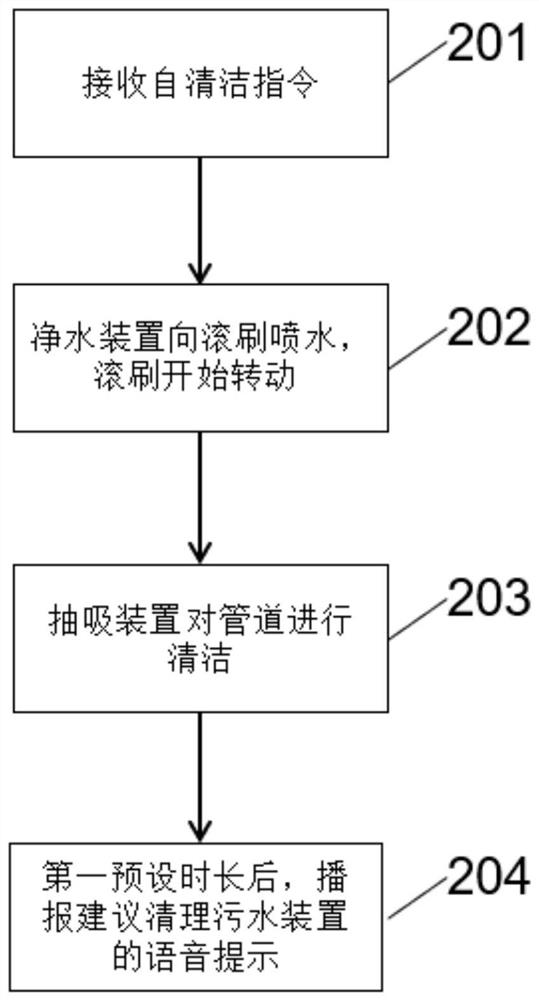

Image

Examples

Embodiment

[0054] Such as Figure 1-Figure 7 As shown, this embodiment provides a control method for a floor washing machine, using a floor washing machine with a water purification device 1, a sewage discharge device 2, a suction device 3 and a ground brush 4, including: a first mode, a second mode , third mode and fourth mode.

[0055] The first mode: receive the start-up command, and broadcast the first voice information, according to the start-up command, start the water purification device 1, the sewage device 2, the suction device 3 and the ground brush 4, the water purification device 1 sprays water to the ground brush 4, and pumps water. The vacuum degree of the suction device 3 is 2-6Kpa, the load of the floor brush 4 is 2000-2500Rpa, and the water volume is 10-30ML / min.

[0056] Specifically, the first mode is preferably the standard mode of the washing machine. The user can start the first mode by pressing the power button on the washing machine. The electrolyzed water devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com